Disposable butadiene-acrylonitrile rubber modified PVC glove and preparation method thereof

A technology of nitrile rubber and liquid nitrile rubber, used in gloves, other household appliances, household components, etc., can solve the problems of poor solvent resistance, uneven vulcanization, poor elasticity of gloves, etc., to achieve excellent wearing comfort and good hand feel , The effect of high solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

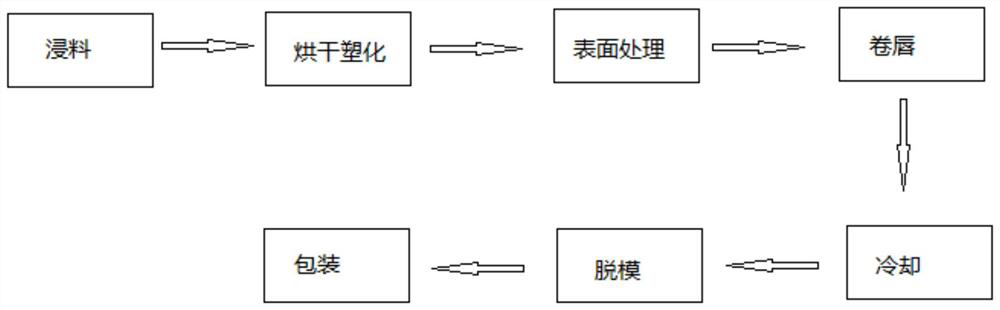

[0040] Example 1: A preparation method of disposable nitrile rubber modified PVC gloves, including the following steps:

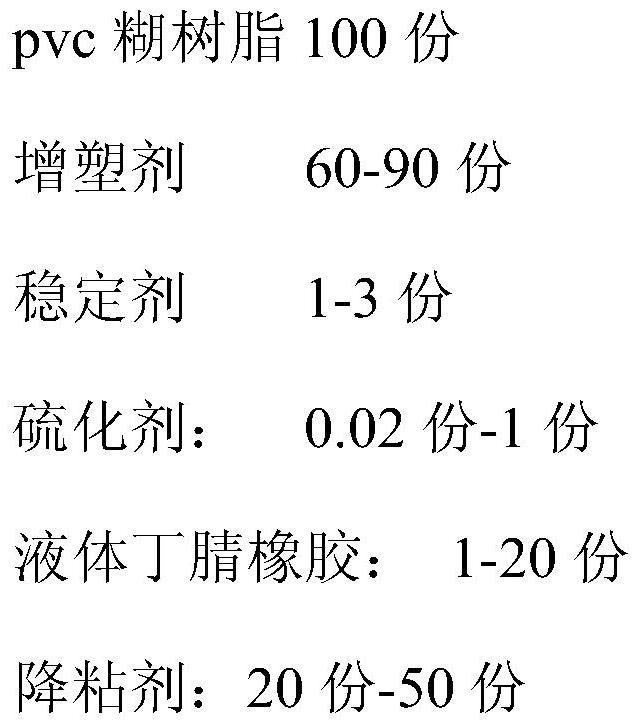

[0041] Add 100 parts of pvc paste resin, 60 parts of plasticizer (dioctyl phthalate (DOP), 1 part of stabilizer (calcium stearate), 0.05 parts of vulcanizing agent (di-tert-butyl permeate) into the stirred tank Cumene oxide), 5 parts of liquid nitrile rubber and 20 parts of viscosity reducer (2,2,4-trimethyl-1,3-pentanediol diisobutyrate: hydrocarbon solvent oil=3:1 ), turn on the agitator, stir quickly (speed at 1000-1500r / min) for 2 hours, after filtering the prepreg, use a pump to pump it into the storage tower for vacuum degassing for 36 hours and save it for use.

[0042] The ceramic hand mold enters the PVC prepreg emulsion tank for pre-soaking for 6 seconds. After soaking, it is plasticized at 200°C for 8 minutes, and then the nitrile rubber is modified by rolling lip, surface treatment, rolling lip, and cooling packaging. Sexual PVC gloves. The glove f...

Embodiment 2

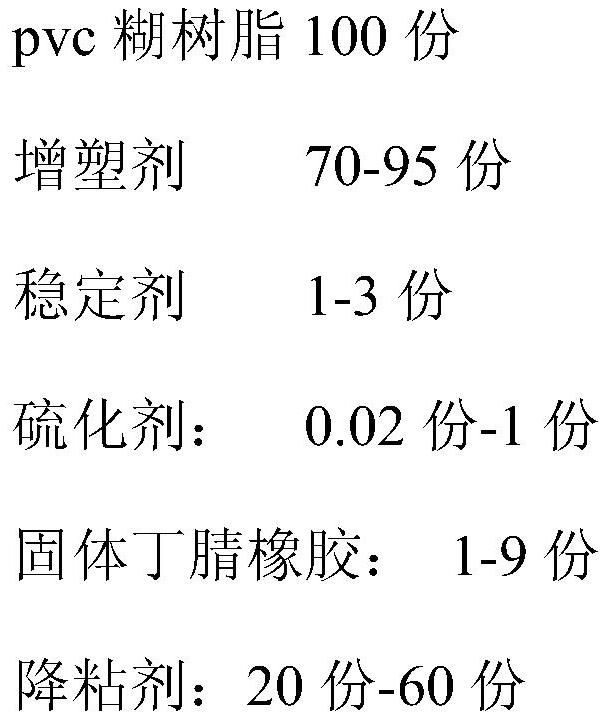

[0043] Example 2: A preparation method of disposable nitrile rubber modified PVC gloves, including the following steps: pass 5 parts of solid nitrile rubber through a cutting machine to cut into particles with a maximum size of no more than 0.8 cm, and add them to a stirring tank 35 parts of plasticizer, high-speed stirring at 40 degrees to dissolve for 72 hours; then add 100 parts of PVC paste resin, 35 parts of plasticizer (dioctyl phthalate (DOP), 1 part of stabilizer (stearin) into the reactor Calcium acid), 0.05 parts of vulcanizing agent (di-tert-butyl cumene peroxide), 20 parts of viscosity reducer (2,2,4-trimethyl-1,3-pentanediol diisobutyrate: hydrocarbon Solvent oil=3:1), stir quickly (speed at 1000-1500r / min) for 2 hours, and then use a pump to pass it through the filter device and input it to the storage tower for vacuum deaeration (still deaeration, Defoamer (defoaming) for 36h to be used.

[0044] The ceramic hand mold enters the PVC prepreg emulsion tank for pre-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com