Antistatic thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer and elastomer material technology, applied in the field of materials, can solve the problems of damage, destroy sensitive electronic components, generate a lot of static electricity, etc., and achieve the effects of wide applicability, green preparation, and good antistatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Embodiments of the present invention also provide a method for preparing an antistatic thermoplastic elastomer material comprising the following steps:

[0035] Step 1: dissolving white oil in styrene-based elastomer, and stirring at room temperature for 15 minutes until white oil is completely absorbed by styrene-based elastomer to obtain the first mixture;

[0036] Step 2: The mass percentage of each component is: polypropylene 2%-10%, inorganic filler 0.1%-10%, polymer antistatic agent 0.1%-10%, lubricant 0.1%-1%, antioxidant 0.1% %-1%, stirred at room temperature for 10mins until uniformly mixed to obtain the second mixture;

[0037] Step 3: dissolving the second mixture in the first mixture, kneading and dispersing after mixing evenly, and processing and molding to obtain the conductive thermoplastic elastomer material.

[0038] Further, a 48:1 twin-screw extruder is used for extrusion granulation processing, wherein the extrusion granulation temperature is 100-30...

Embodiment 1

[0043] Step 1: dissolving white oil in styrene-based elastomer, and stirring at room temperature for 15 minutes until white oil is completely absorbed by styrene-based elastomer to obtain the first mixture;

[0044] Step 2: The mass percentage of each component is: polypropylene 2%-10%, inorganic filler 0.1%-10%, polymer antistatic agent 0.1%-10%, lubricant 0.1%-1%, antioxidant 0.1% %-1%, stirred at room temperature for 10mins until uniformly mixed to obtain the second mixture;

[0045] Step 3: dissolving the second mixture in the first mixture, kneading and dispersing after mixing evenly, and processing and molding to obtain the conductive thermoplastic elastomer material.

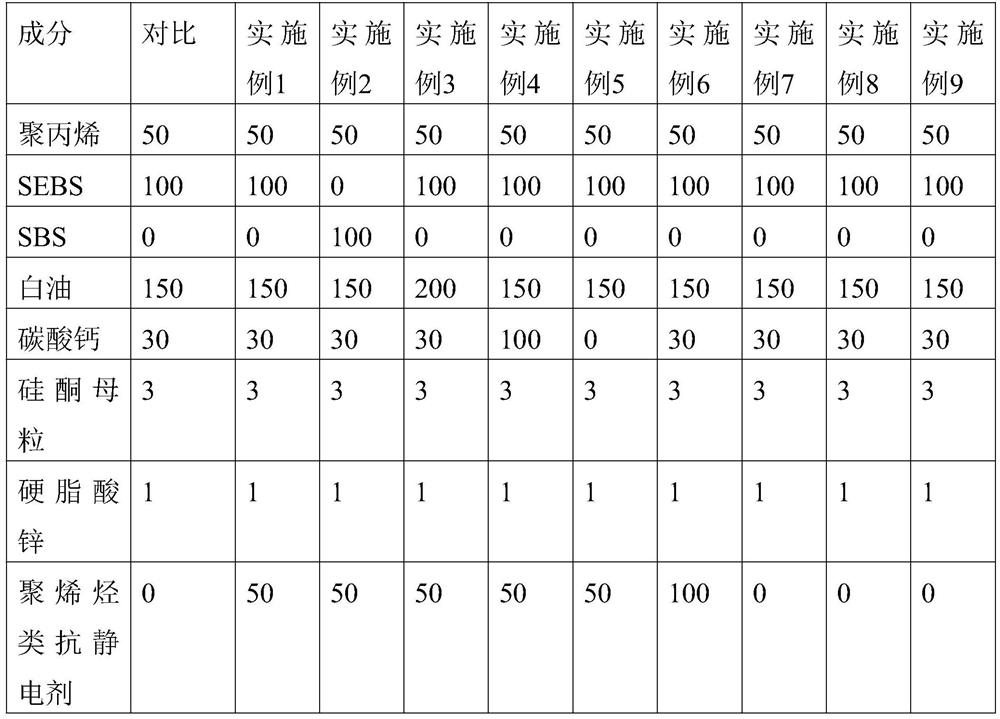

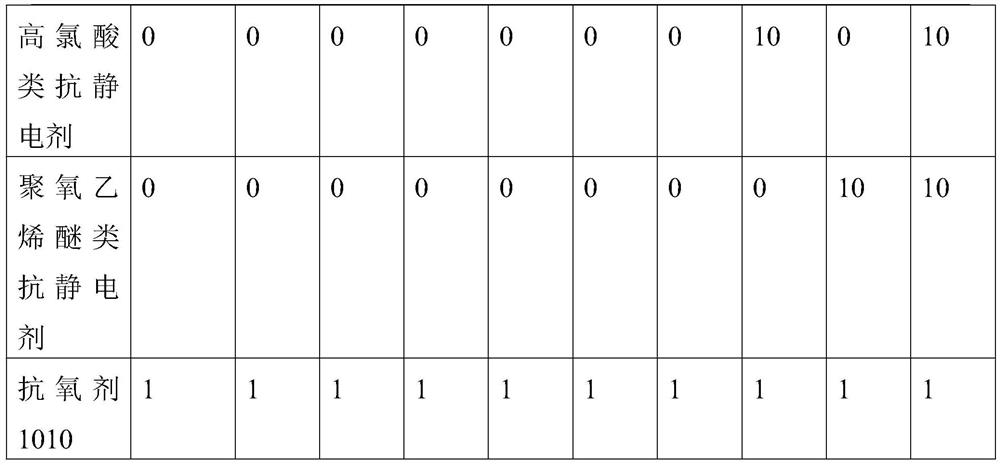

[0046] Embodiment 2~Example 9 test procedure is identical with embodiment 1, and difference is that the percentage of each component is different as following table 1

[0047]

[0048]

[0049] Table 1

[0050] The antistatic thermoplastic elastomer material that embodiment 1~embodiment 9 makes is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com