Flame-retardant toughened polylactic acid-based composite material as well as preparation and application thereof

A composite material and polylactic acid technology are applied in the field of flame-retardant and toughened polylactic acid-based composite materials and their preparation, which can solve the problems of poor thermal stability and low melt strength, and achieve improved compatibility, high flame retardant efficiency, The effect of improving the flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

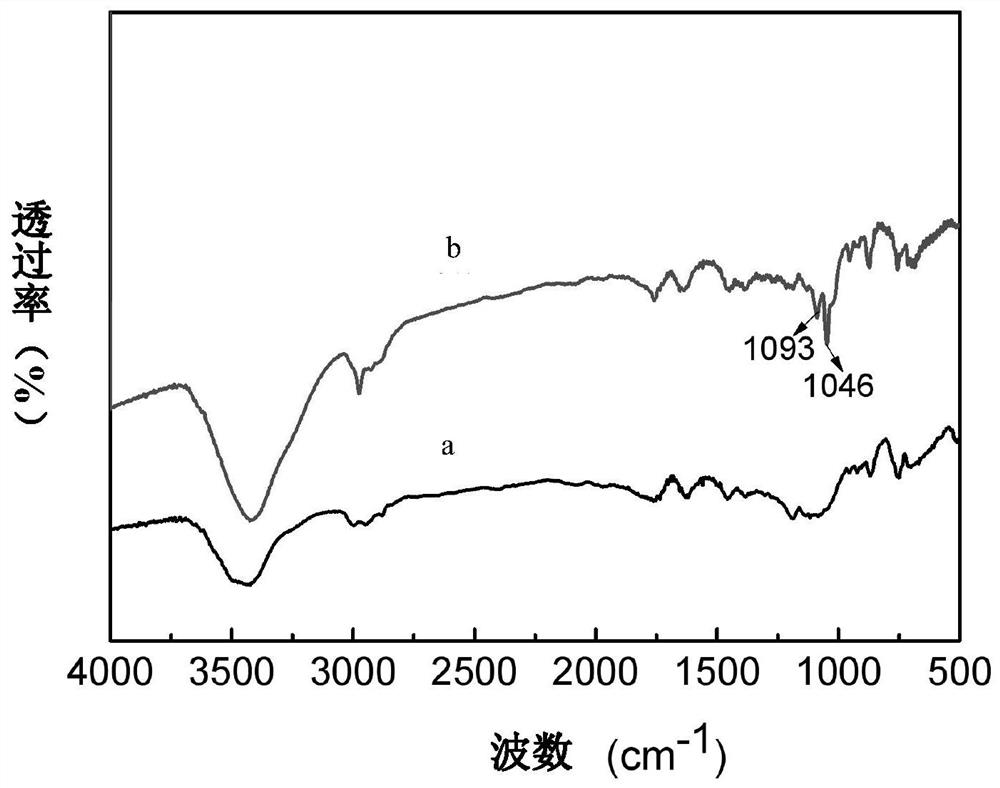

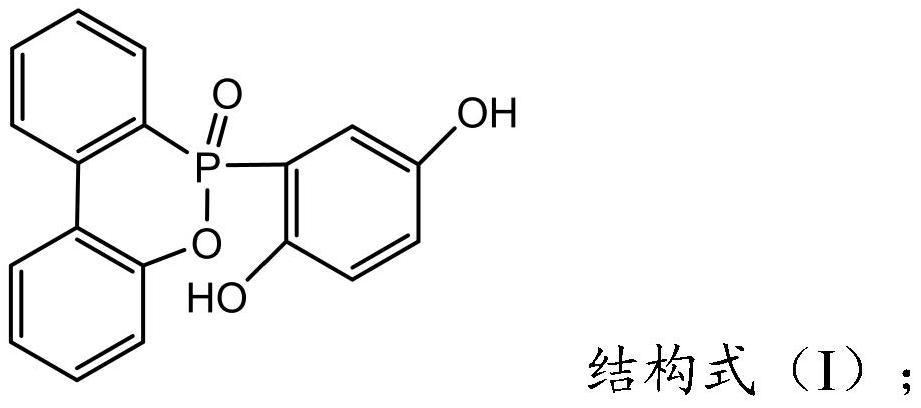

[0067] (1) Preparation of modified flame retardant: first, dry polylactic acid and flame retardant DOPO-HQ at a drying temperature of 80°C and a drying time of 4 hours;

[0068] Then, 20g of the flame retardant DOPO-HQ was mixed evenly with 100g of polylactic acid, and then added to the twin-screw extruder for melt blending. After extrusion, modified flame retardant particles with polylactic acid molecules attached to the surface were obtained.

[0069] Among them, the temperature of each section in the twin-screw extruder is: 170°C for the first section, 180°C for the second section, 190°C for the third section, 190°C for the fourth section, and 185°C for the fifth section. The residence time is 6s;

[0070] (2) Preparation of composite material: 25g (5wt%) of modified flame retardant particles obtained in step (1) and 500g of polylactic acid matrix resin are added to a twin-screw extruder for secondary melt blending, and the twin-screw extruder The temperature of each secti...

Embodiment 2

[0073] (1) Preparation of modified flame retardant: same as step (1) in Example 1;

[0074] (2) Preparation of composite material: 37.5g (7.5wt%) of the modified flame retardant particles obtained in step (1) and 500g of polylactic acid matrix resin are added in a twin-screw extruder to carry out secondary melt blending, and the twin-screw The temperature of each section of the extruder is respectively: the temperature of the first zone is 160°C, the temperature of the second zone is 170°C, the temperature of the third zone is 175°C, the temperature of the fourth zone is 180°C, and the temperature of the fifth zone is 190°C. The screw speed is 260rpm / min, and the feeding frequency is 8Hz.

[0075] Finally, the target polylactic acid-based flame-retardant and toughened composite material particles were prepared.

Embodiment 3

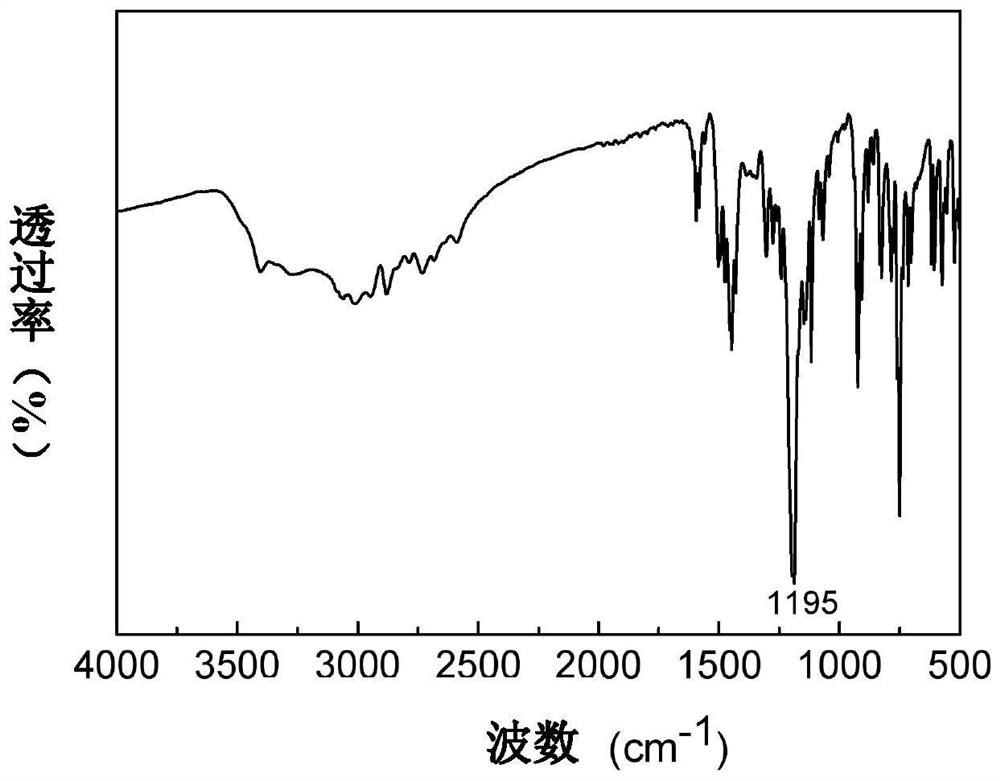

[0077] (1) Preparation of modified flame retardant: first, dry polylactic acid and flame retardant DOPO-MAH at a drying temperature of 80°C and a drying time of 4 hours.

[0078] Then, flame retardant DOPO-MAH 20g (20wt%), mixed with polylactic acid 100g, added in the twin-screw extruder, melt blending, obtained modified flame retardant particles after extrusion,

[0079] Among them, the temperature of each section in the twin-screw extruder is: 170°C for the first section, 180°C for the second section, 190°C for the third section, 190°C for the fourth section, and 185°C for the fifth section. The residence time is 6s;

[0080] (2) Preparation of composite material: 37.5g (7.5wt%) of the modified flame retardant particles obtained in step (1) and 500g of polylactic acid matrix resin are added in a twin-screw extruder to carry out secondary melt blending, and the twin-screw The temperature of each section of the extruder is respectively: the temperature of the first zone is 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com