Electrode and preparation method thereof

A technology of electrode and indium tin oxide, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problem of poor hole injection ability of electroluminescent materials, and achieve the effect of strong hole injection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

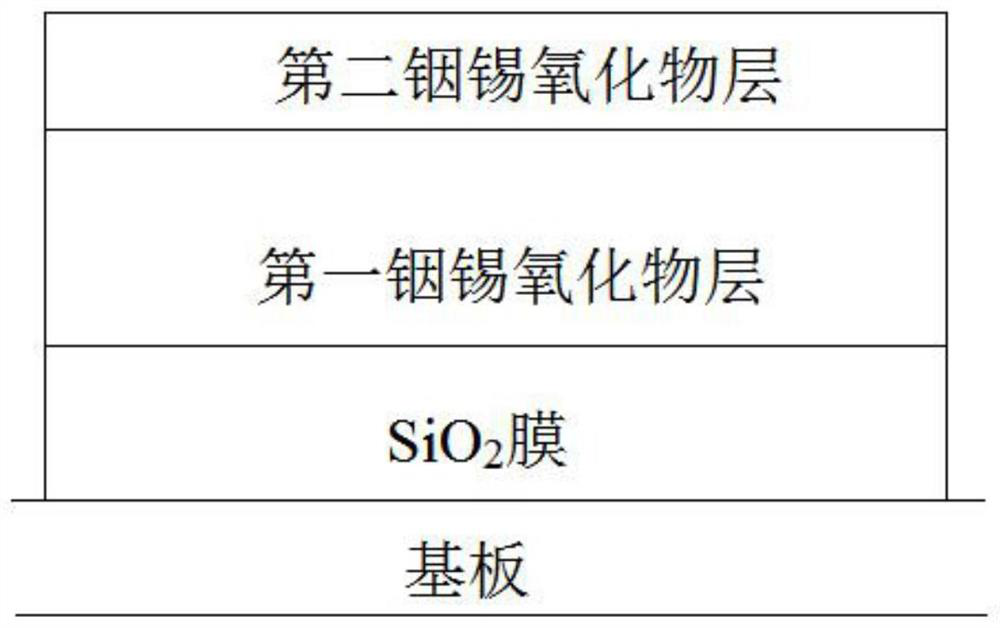

[0028] figure 1 Electrode structure diagram provided for the embodiment of the present invention. Such as figure 1 As shown, the electrode in the present invention is provided with substrate, SiO 2 film, a first indium tin oxide layer, and a second indium tin oxide layer.

[0029] In this embodiment, the substrate is soda lime glass. SiO 2 The membrane is an alkaline ion blocking layer in the electrode, which can prevent the alkaline ions in the soda lime glass from entering the first indium tin oxide layer, maintain ion balance, and ensure the performance of the electrode. The composition ratio of Sn and In in the first ITO layer may be 5%-10%. The composition ratio of Sn and In in the second indium tin oxide layer may be 50% or more.

Embodiment 2

[0031] In order to make the electrode have a high work function and a strong ability to inject holes, the invention also provides an electrode preparation method. Methods include:

[0032] Step 1: Deposit a layer of SiO on the substrate 2 membrane. In this embodiment, the substrate may be soda lime glass. The specific process is: deposit a layer of SiO on soda-lime glass using chemical vapor deposition, physical vapor deposition or sol-gel method. 2 membrane. SiO 2 The membrane can be used as an alkaline ion blocking layer to prevent alkaline ions in the soda lime glass from entering the first indium tin oxide layer to destroy ion balance and affect electrode performance.

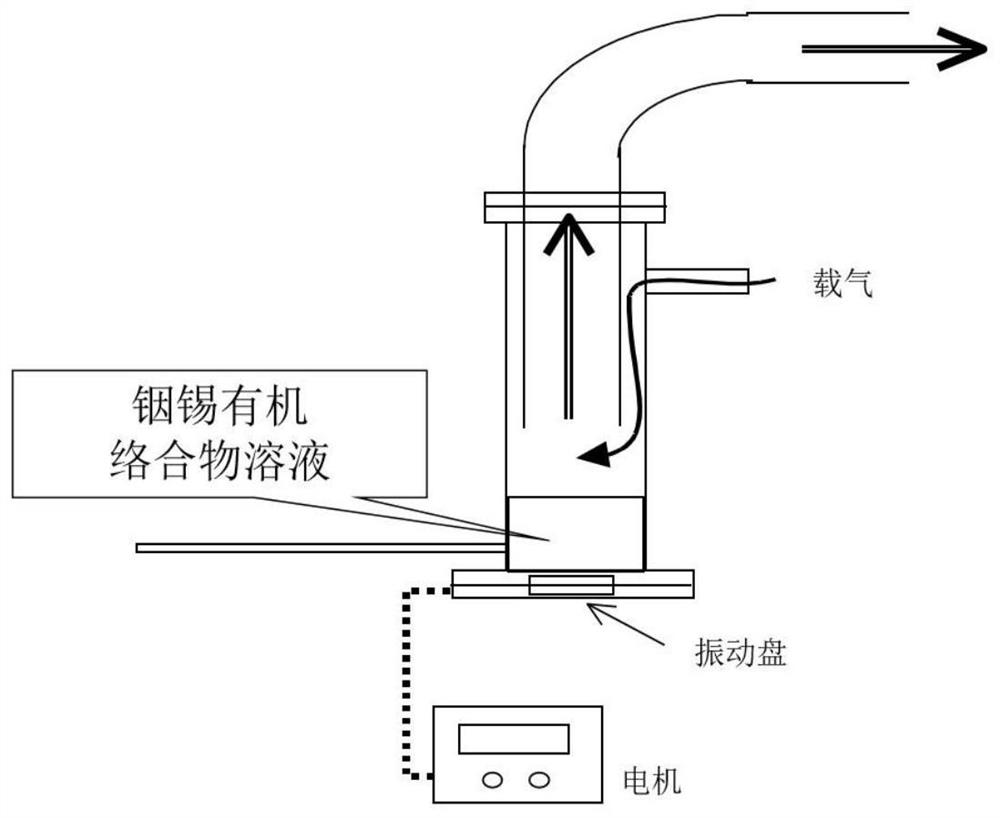

[0033] Step 2: Prepare the first indium tin organic complex solution, wherein the proportions of tin and indium are respectively controlled at 5%-10%; atomize the first indium tin organic complex solution; atomize the atomized The first complex is decomposed into indium oxide and tin oxide; then the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com