A highly integrated modular hub motor

A wheel hub motor, a highly integrated technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of poor adaptability, high temperature rise, poor performance, etc., to ensure high-efficiency continuous operation, speed up maintenance, The effect of increasing the reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0040] A highly integrated modular wheel hub motor of the present invention includes a highly integrated motor and a parallel cooling system.

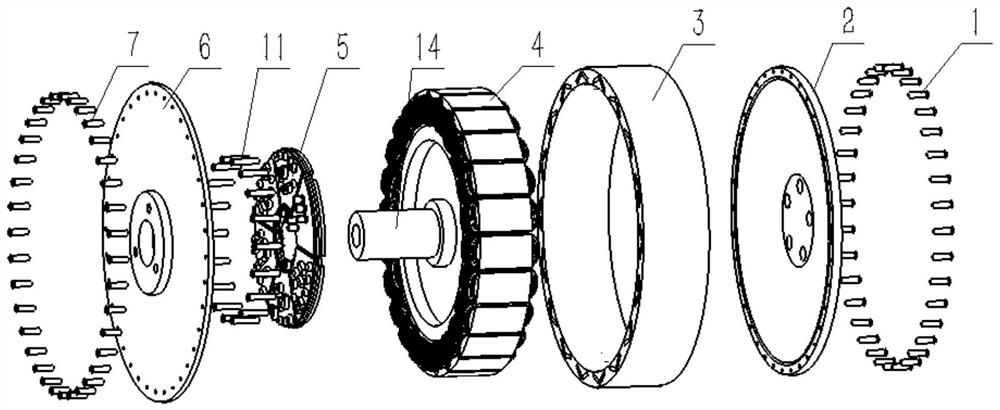

[0041] like figure 1 As shown, the highly integrated motor includes fastening bolt A1, front closed end cover 2, rotating assembly 3, stator assembly 4, control module assembly 5, rear closed end cover 6, fastening bolt B7, fastening bolt C11 and the main shaft 14.

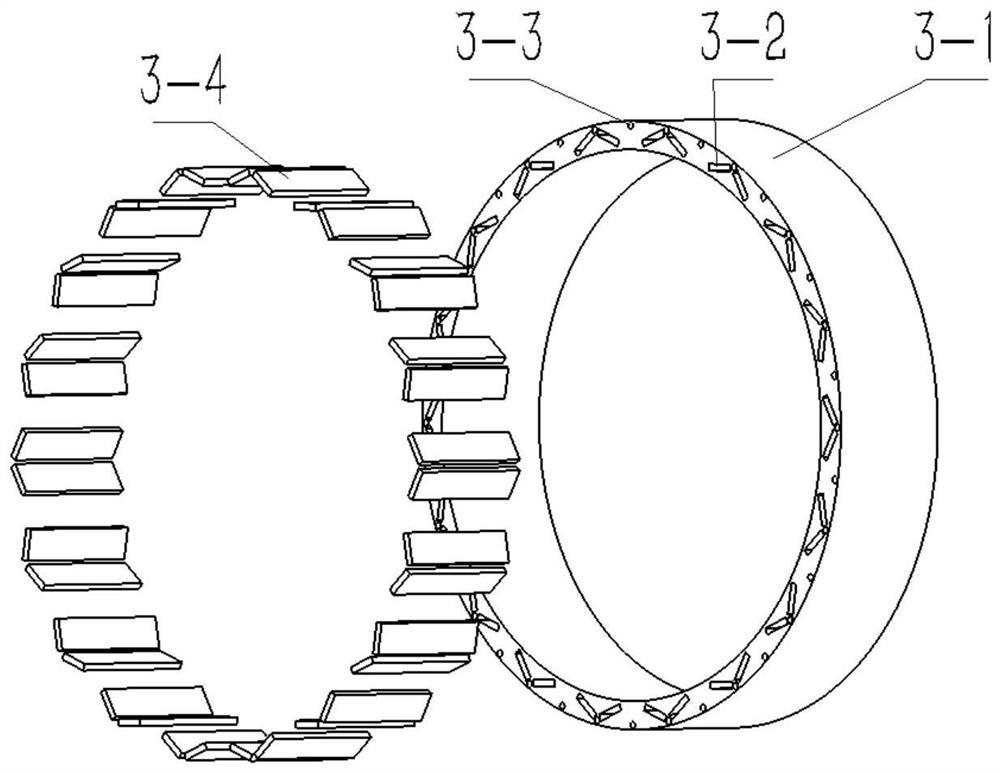

[0042] like figure 2 As shown, the rotating assembly 3 includes a rotor 3-1 and a built-in V-shaped permanent magnet 3-4. The two sides of the rotor 3-1 are evenly provided with bolt fixing holes 3-3, and the sides of the rotor 3-1 are also processed with permanent magnets. Magnet assembly groove 3-2; the front closed end cover 2 is connected to the bolt fixing hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com