Insecticidal aerosol and preparation method thereof

An aerosol and solvent technology, applied in the field of anti-aging composition and its preparation, can solve the problems of short residence time, not solving the inhibition of pesticide efficacy, poor compatibility, etc., and achieves good insecticidal effect, significant The effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 insecticidal aerosol

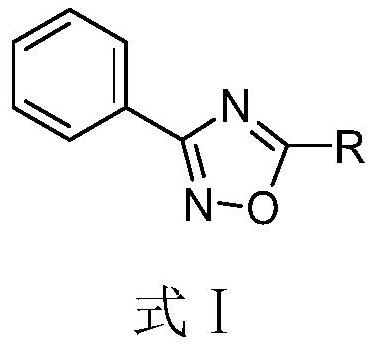

[0034] Component A: 0.2-0.7% by weight of 1,2,4-oxadiazole derivatives represented by formula I;

[0035] Component B: 1.5-2% by weight of marigold extract;

[0036] Component C: 3.3-73.3% by weight of solvent;

[0037] Component D: 25-94% by weight of propellant.

[0038]

[0039] Marigold extract is prepared by the following methods:

[0040]S1. Raw material preparation: wash and dry the marigolds and pulverize them to obtain marigold powder;

[0041] S2. Ultrasonic-assisted water extraction: Add 10g of marigold powder into 50mL of water, stir evenly, heat to 35°C, ultrasonic (power 1000W) assisted extraction for 0.5h, filter, and retain the filter residue;

[0042] S3. Supercritical fluid extraction: extract the filter residue obtained in step S2 through supercritical fluid extraction, and the supercritical fluid extraction conditions are: extraction pressure: 22MPa; extraction temperature: 35°C; CO 2 Flow rate: 7L / h; extra...

Embodiment 2

[0053] Embodiment 2 Insecticidal aerosol

[0054] Component A: 0.3% by weight of 1,2,4-oxadiazole derivatives represented by formula I;

[0055] Component B: 1.2% by weight of marigold extract;

[0056] Component C: 35% by weight of C10-18 alkane solvent;

[0057] Component D: 63.5% by weight of propane.

[0058]

[0059] Marigold extract is prepared by the following methods:

[0060] S1. Raw material preparation: wash and dry the marigolds and pulverize them to obtain marigold powder;

[0061] S2. Ultrasonic-assisted water extraction: Add 10g of marigold powder into 100mL of water, stir evenly, heat to 50°C, ultrasonic (power 1200W) assisted extraction for 1h, filter, and retain the filter residue;

[0062] S3. Supercritical fluid extraction: extract the filter residue obtained in step S2 through supercritical fluid extraction, and the supercritical fluid extraction conditions are: extraction pressure: 27MPa; extraction temperature: 40°C; CO 2 Flow rate: 12L / h; extrac...

Embodiment 3

[0074] Embodiment 3 insecticidal aerosol

[0075] Component A: 0.5% by weight of 1,2,4-oxadiazole derivatives represented by formula I;

[0076] Component B: 1.5% by weight of marigold extract;

[0077] Component C: 73.9% by weight of C2-C8 small molecule alcohol solvents;

[0078] Component D: 25% by weight of dimethyl ether.

[0079]

[0080] Marigold extract is prepared by the following methods:

[0081] S1. Raw material preparation: wash and dry the marigolds and pulverize them to obtain marigold powder;

[0082] S2. Ultrasonic-assisted water extraction: Add 10g of marigold powder into 70mL of water, stir evenly, heat to 42°C, ultrasonic (power 1100W) assisted extraction for 0.75h, filter, and retain the filter residue;

[0083] S3. Supercritical fluid extraction: extract the filter residue obtained in step S2 through supercritical fluid extraction, and the supercritical fluid extraction conditions are: extraction pressure: 25MPa; extraction temperature: 37°C; CO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com