Low-GI healthy sugar and preparation method and use thereof

A technology of healthy sugar and sucrose, applied in confectionary, application, confectionary industry, etc., can solve the problems of chromosomal abnormality, bladder cancer, safety cannot be guaranteed, and xylitol is not easy to decompose, so as to promote electrolyte balance and facilitate Carrying and improving the effect of sugar metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A low GI healthy sugar, which comprises the following components in parts by weight: 96 parts of sucrose, 4 parts of L-arabinose, 1 part of inositol, and 1 part of complex electrolyte.

[0043] The composite electrolyte includes sodium chloride, potassium chloride, magnesium sulfate and calcium gluconate, and the weight ratio of the sodium chloride, potassium chloride, magnesium sulfate and calcium gluconate is 1:10:25:10.

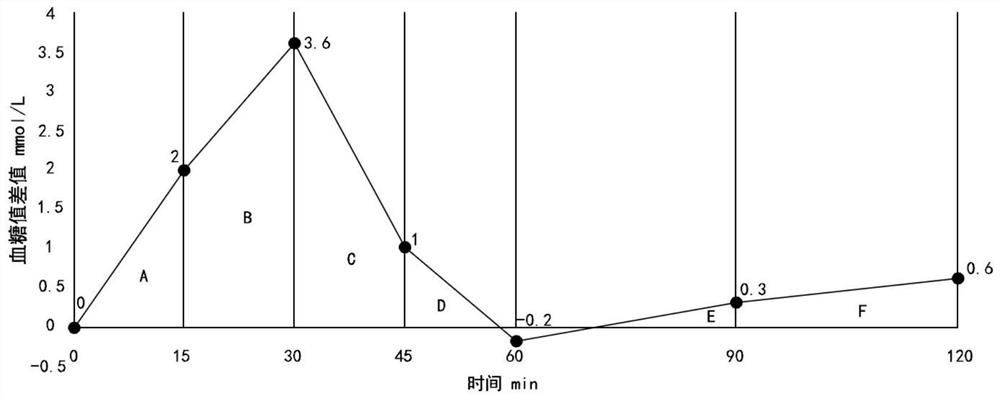

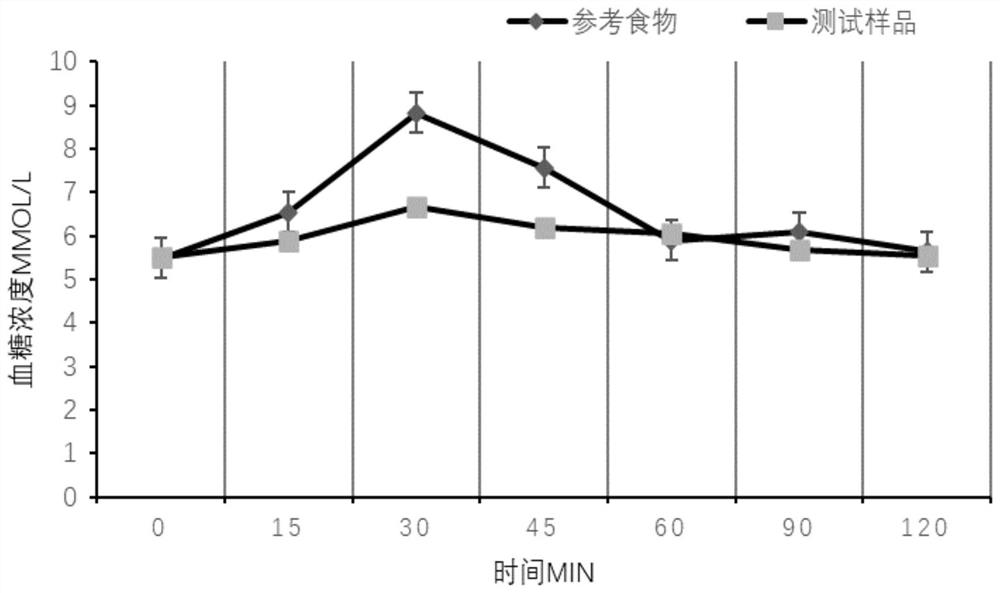

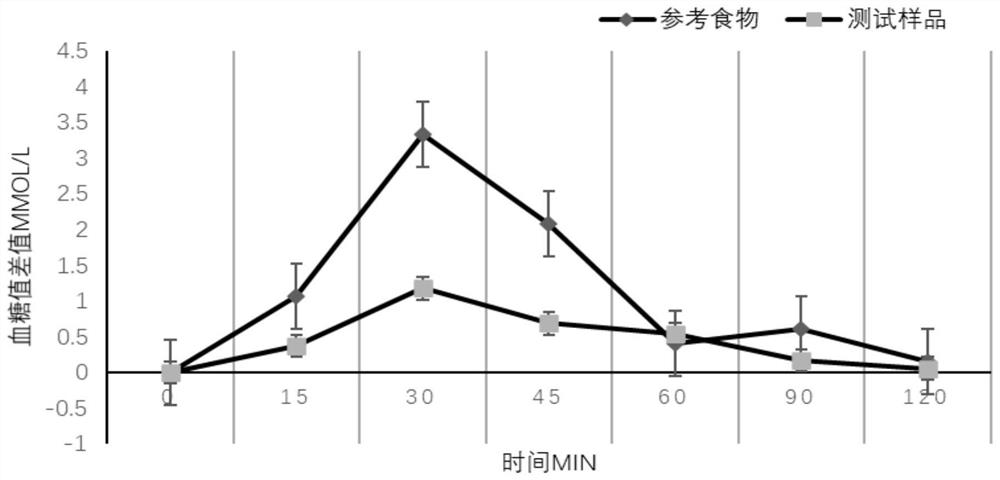

[0044] The low GI healthy sugar of the present invention has a GI value of ≤55.

[0045] The preparation method of the above-mentioned low GI healthy sugar comprises the following steps:

[0046] S1. Grind the solid granular L-arabinose, inositol and composite electrolyte through a jet mill for homogenization. The homogenization pressure is 0.5-0.9 MPa. Adjust the homogenization pressure in time according to the crushing situation, and the homogenization time is 30 minutes;

[0047] S2. After crushing and homogenizing, pass the mixture of L-arabino...

Embodiment 2

[0052] A low GI healthy sugar, which comprises the following components in parts by weight: 93 parts of sucrose, 10 parts of L-arabinose, 1 part of inositol, and 1 part of complex electrolyte.

[0053] The composite electrolyte includes sodium chloride, potassium chloride, magnesium sulfate and calcium gluconate, and the weight ratio of the sodium chloride, potassium chloride, magnesium sulfate and calcium gluconate is 1:10:25:10.

[0054] The low GI healthy sugar of the present invention has a GI value of ≤55.

[0055] The preparation method of the above-mentioned low GI healthy sugar comprises the following steps:

[0056] S1. Grind the solid granular L-arabinose, inositol and composite electrolyte through a jet mill for homogenization. The homogenization pressure is 0.5-0.9 MPa. Adjust the homogenization pressure in time according to the crushing situation. The homogenization time is 28 minutes;

[0057] S2. After crushing and homogenizing, pass the mixture of L-arabinose,...

Embodiment 3

[0062] A low GI healthy sugar, which comprises the following components in parts by weight: 97 parts of sucrose, 6 parts of L-arabinose, 2 parts of inositol, and 0.5 parts of complex electrolyte.

[0063] The composite electrolyte includes sodium chloride, potassium chloride, magnesium sulfate and calcium gluconate, and the weight ratio of the sodium chloride, potassium chloride, magnesium sulfate and calcium gluconate is 1:10:25:10.

[0064] The low GI healthy sugar of the present invention has a GI value of ≤55.

[0065] The preparation method of the above-mentioned low GI healthy sugar comprises the following steps:

[0066] S1. Grind the solid granular L-arabinose, inositol and composite electrolyte through a jet mill for homogenization. The homogenization pressure is 0.5-0.9 MPa. Adjust the homogenization pressure in time according to the crushing situation. The homogenization time is 25-25 MPa. 3530 / 25 / 28min;

[0067] S2. After crushing and homogenizing, pass the mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com