Preparation method of novel protein ingredients, being high in oil absorption and high in emulsifying and capable of realizing gelatinization at low temperature

A high oil-absorbing, low-temperature glue technology, applied in protein food processing, animal protein processing, protein food ingredients, etc., can solve problems such as imperfections, achieve low gel temperature, improve protein properties, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

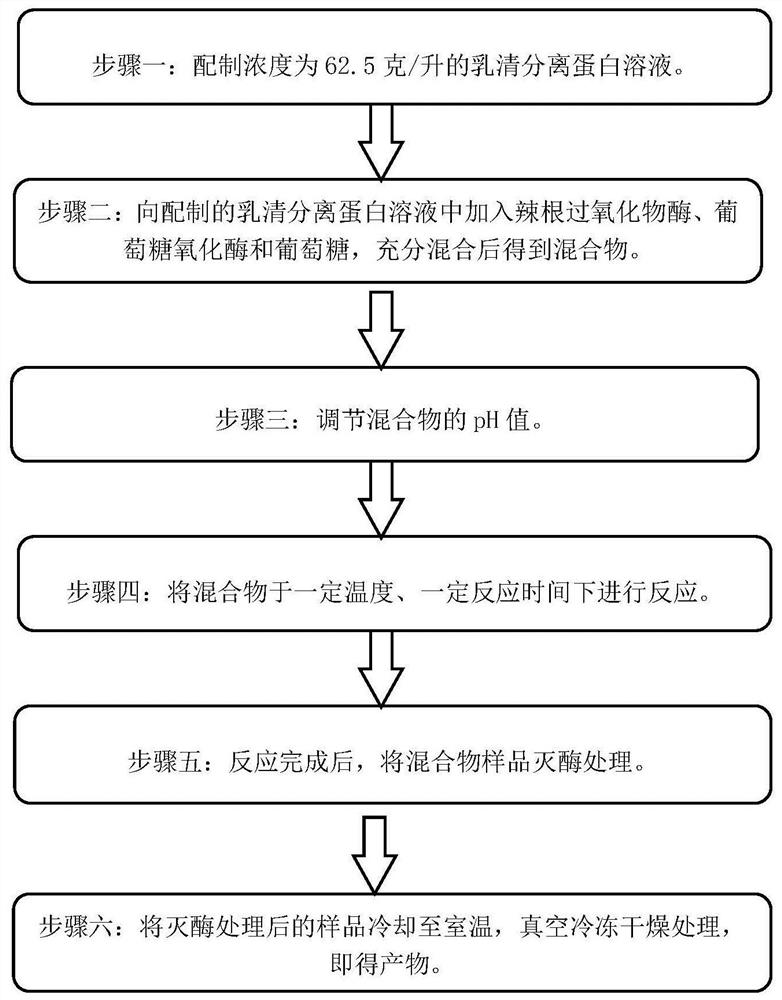

[0035] Embodiment 1: In this embodiment, a novel protein ingredient preparation method with high oil absorption, high emulsification and low-temperature gelation includes the following steps:

[0036] Step 1: Prepare a whey protein isolate solution with a concentration of 62.5 g / L.

[0037] Step 2: Add horseradish peroxidase, glucose oxidase and glucose to the prepared whey protein isolate solution, and mix thoroughly to obtain a mixture.

[0038] Step 3: Adjust the pH value of the mixture.

[0039] Step 4: subjecting the mixture to a modification reaction at a certain temperature and a certain reaction time.

[0040] Step 5: After the reaction is completed, the mixture sample is subjected to enzyme inactivation treatment.

[0041] Step 6: Cool the sample after the enzyme-inactivating treatment to room temperature, and vacuum freeze-dry to obtain a protein ingredient with high oil absorption, high emulsification and low-temperature gelation.

specific Embodiment approach 2

[0042] Embodiment 2: In Embodiment 1, the novel protein ingredient preparation method with high oil absorption, high emulsification and low-temperature gelation, the pH value of the whey protein isolate solution in step 1 is 7.0.

specific Embodiment approach 3

[0043] Embodiment 3: In Embodiment 1, according to the method for preparing novel protein ingredients with high oil absorption, high emulsification and low-temperature gelation, the amount of horseradish peroxidase added in step 2 is 200 enzyme activity units / gram of protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com