Billet discharge system of square billet continuous casting machine and billet discharge control method thereof

A billet continuous casting and billet casting technology, which is applied to the billet unloading system of a billet continuous caster and its billet control field, can solve the problems of limited production space, the length cannot meet the process requirements, and the normal layout cannot be used, and realizes automation. Control, improve uniform cooling effect, reduce labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

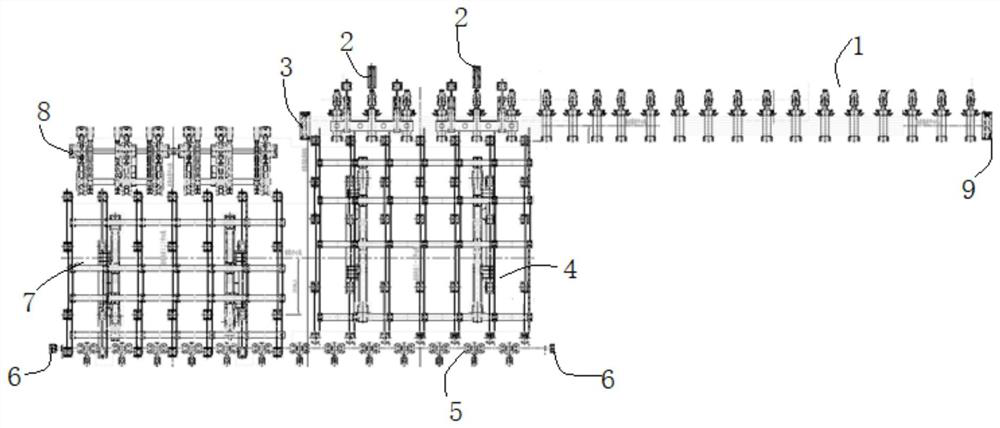

[0037] like figure 1 As shown, a billet discharge system of a billet continuous casting machine in this embodiment includes a hot delivery roller table 1, a billet discharge cooling bed 1, a transition roller table 5, and a billet discharge cooling bed 2 7, and the hot delivery roller table 1 The outlet end is provided with an alignment pushing machine 2, and the direction of pushing steel of the alignment pushing machine 2 is perpendicular to the conveying direction of the hot-feeding roller table 1. 2. Push the fixed-length cast slab to the billet cooling bed-4, and the conveying direction of the billet cooling bed-4 is consistent with the steel pushing direction of the steel pushing machine 2; the transition roller table 5 is arranged on the billet cooling bed-4 The outlet end, and the conveying direction of the transition roller table 5 is perpendicular to the conveying direction of the first billet cooling bed 4, and the transition roller table 5 is used to transfer the f...

Embodiment 2

[0046] The billet discharge control method of the billet continuous casting machine billet discharge system in this embodiment adopts the billet continuous caster billet discharge system in Embodiment 1, utilizes infrared cluster automatic chain control, and implements according to the following process:

[0047] S1. The hot delivery roller table 1 transports the slab to the front end of the lifting baffle 3. An infrared camera is installed at the end of the lifting baffle 3 to monitor the deceleration of the slab running to the lifting baffle 3. 1, slab quantity measurement, slab in place stop signal, a total of three signals; when the infrared camera measures the slab quantity, it sends a stroke signal to the linear sensor built in the hydraulic cylinder of the alignment pusher 2, and the alignment pusher 2 pushes the slab to the The billet cooling bed-4 puts steel on the position, then returns to the original position and sends a signal to the billet cooling bed-4, the bille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com