Ultrasonic shot blasting device for shaft parts

A shaft parts, ultrasonic shot peening technology, applied in the direction of abrasive feeding device, used abrasive processing device, abrasive jetting machine tools, etc., can solve the problem of inconsistent shot peening intensity on the upper and lower surfaces of shaft parts, and achieve improvement Shot peening efficiency and the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

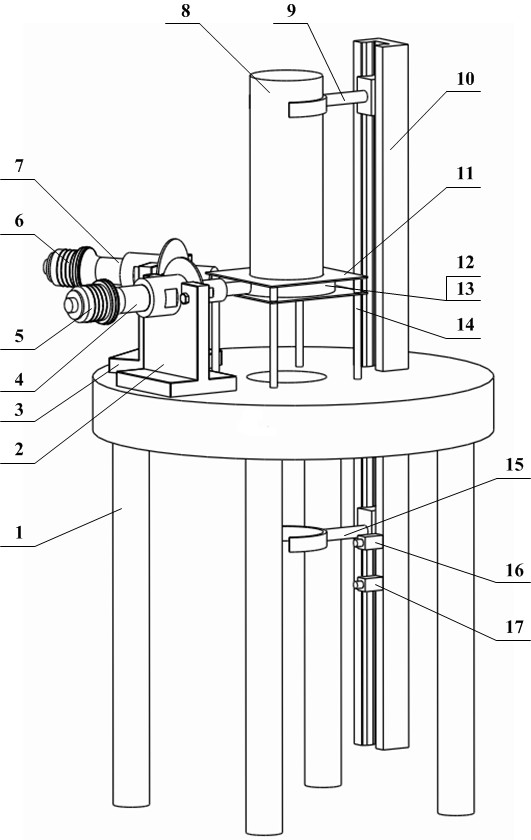

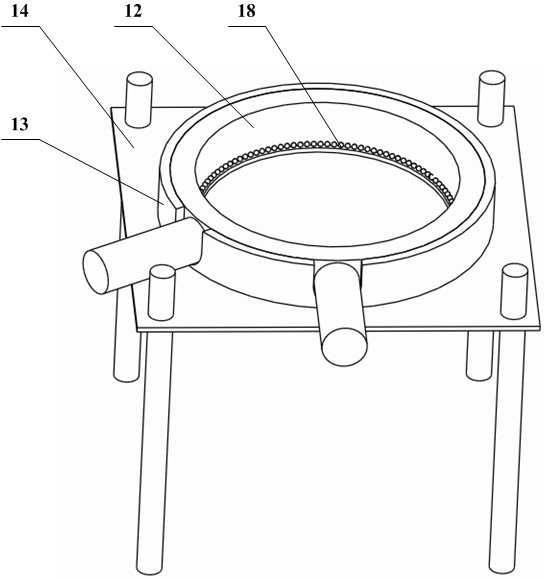

[0015] Below according to specific embodiment the present invention will be further described, see Figure 1~Figure 2 , an ultrasonic shot peening device for shaft parts, a workbench 1, an ultrasonic vibrating device, and a clamping device, is characterized in that the ultrasonic vibrating device consists of a transducer A5, a horn A4, a transducer B6, an amplitude Composed of rod B7 and circular tool head 12, the ultrasonic vibration head composed of transducer A5 and horn A4 is equal to the ultrasonic vibration head composed of transducer B6 and horn B7, with a phase difference of 90 degree, and one group of ultrasonic vibration heads produces radial vibration, and the other group produces bending vibration. The connection points of horn A4 and horn B7 on the ring tool head 12 differ by a quarter wavelength, and the ultrasonic vibration device passes The support A2 and the support B3 are installed on the workbench 1, and the workbench 1 is provided with a through hole, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com