Solid rocket engine overall parameter design method

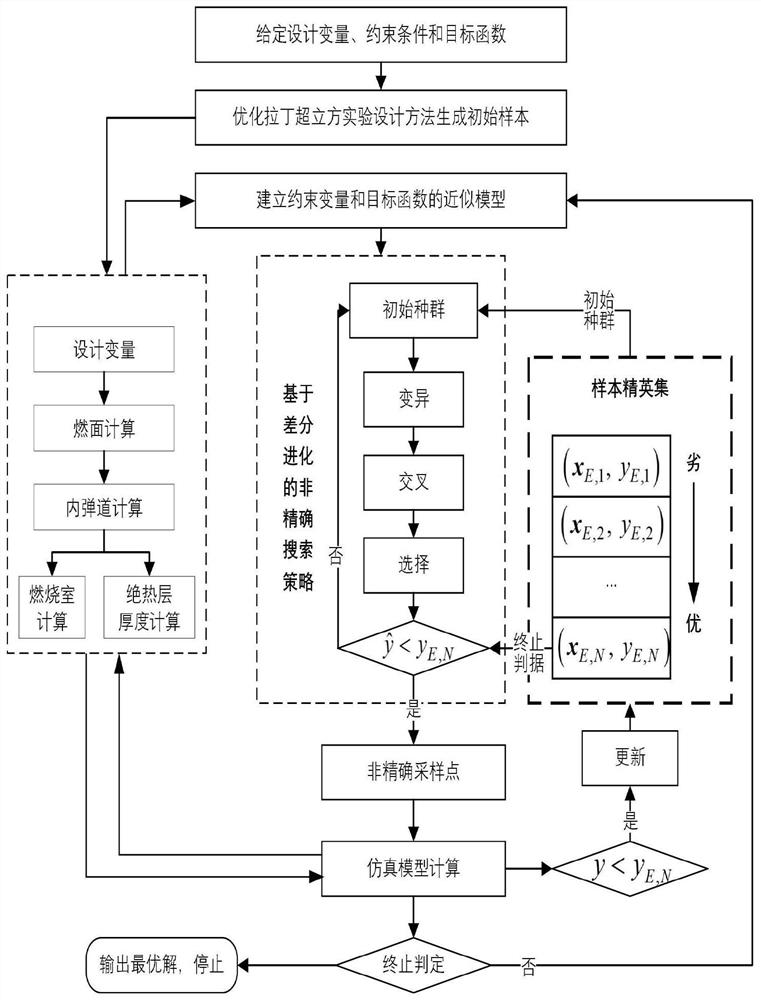

An overall parameter, solid rocket technology, applied in the aerospace field, can solve problems such as poor performance, difficult to obtain optimal design results, increase design cycle and time, etc., to achieve comprehensive performance, improve overall design efficiency and comprehensive performance, The effect of reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

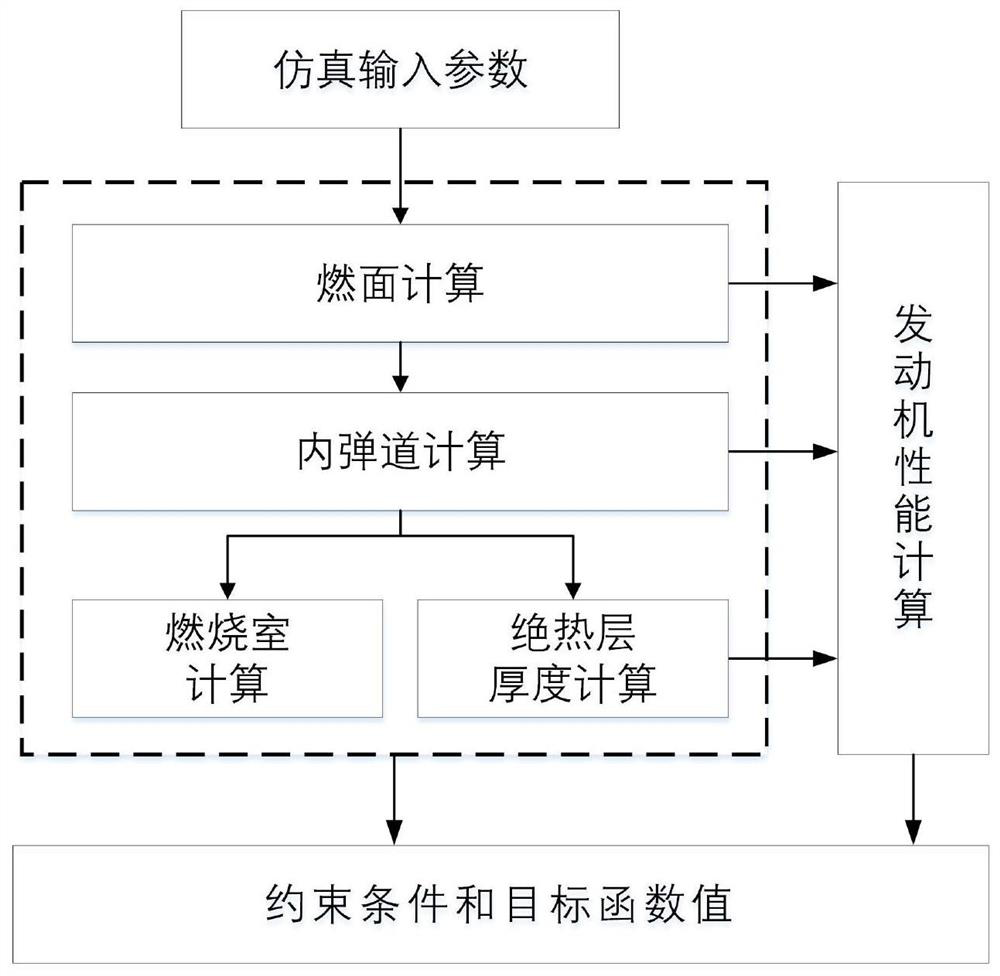

Method used

Image

Examples

Embodiment 1

[0152] Structural parametric design of two-dimensional star hole grain engine:

[0153] Index requirements: engine outer diameter: 260mm; total weight: ≤63kg; skirt spacing: 600mm; nozzle length: 200mm; working temperature: -40℃~50℃; normal temperature (20℃) average thrust: ≥23kN; Total flushing: ≥103kN·s, working time: 4.5s.

[0154] Charge configuration: star hole type, the number of star angles is 6, and the front and rear end faces are not covered.

[0155] Design variables: selected as throat diameter Dt, expansion ratio ε, reference burning rate r0 (6MPa), star hole charge configuration parameters (circumscribed circle diameter D, angle fraction λ, star tip arc radius r, star edge half angle θ , inscribed diameter d), and its variation range is shown in Table 1 below.

[0156] Table 1 Variation range of design variables

[0157]

[0158]

[0159] Propellant parameters: density 1770, pressure index 0.3, burning rate temperature sensitivity coefficient 0.002, gas ...

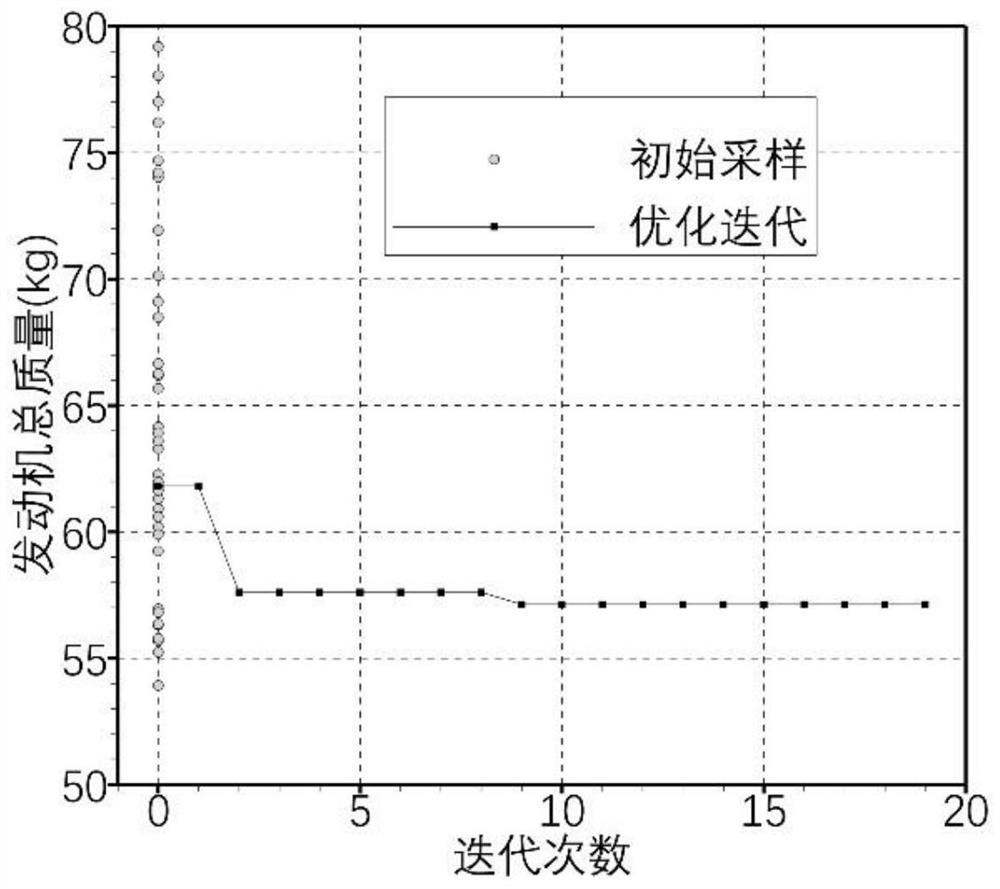

Embodiment 2

[0175] Wing post engine design:

[0176] Design requirements: The outer diameter of the engine is 915mm, the total length of the engine is less than or equal to 5400, the working temperature is -40°C to 50°C; .

[0177] Charge configuration: rear wing column type, the number of rear wings is 9, and the diameter of the inner hole is 250mm.

[0178] Propellant parameters: density 1770, pressure index 0.35, burning rate temperature sensitivity coefficient 0.002, gas specific heat ratio 1.17, characteristic velocity changes with pressure as shown in Table 4 below.

[0179] Table 4

[0180] Pressure (MPa) Characteristic speed (m / s) 5 1560 6 1570 7 1580 8 1590 9 1600

[0181] Shell material: the tensile strength is 1715MPa, and the yield stress is 1370MPa.

[0182] Heat insulation layer material: the density is 1200, the ablation rate is 0.2mm / s, and the thickness allowance is 0.5mm.

[0183] Design variables: selected as throat diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com