Novel mechanical control circuit and mode of frequency converter

A frequency converter, a new type of technology, applied in the direction of machine/engine, liquid variable capacity machinery, AC motor control, etc., can solve the problem that the frequency converter cannot detect the DC bus voltage machine control function, etc., to ensure the power supply capacity and service life. , easy to replace, improve the effect of system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

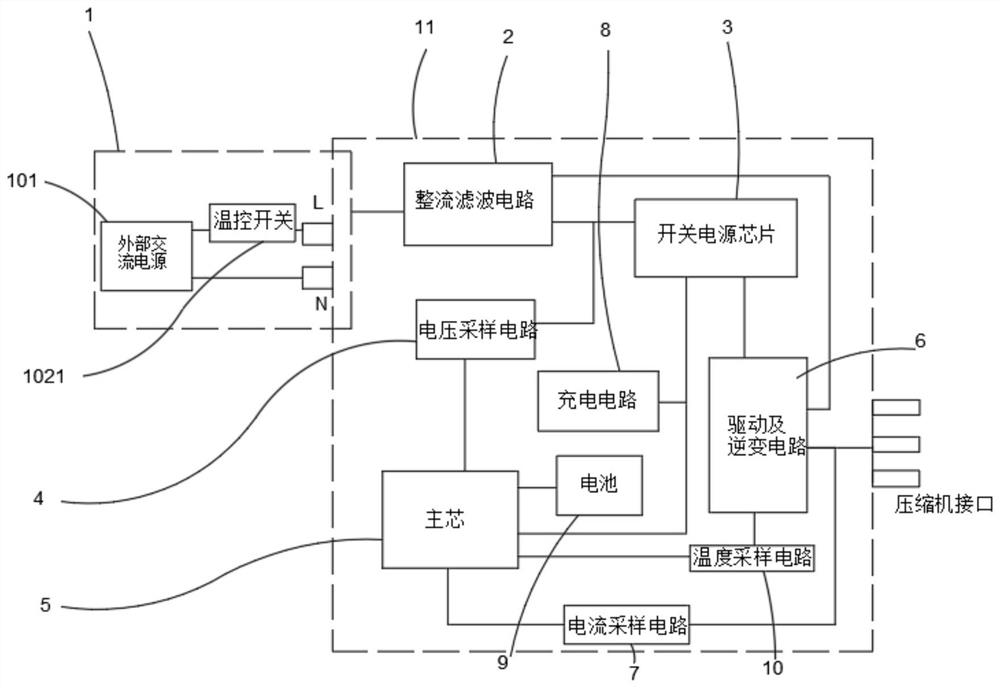

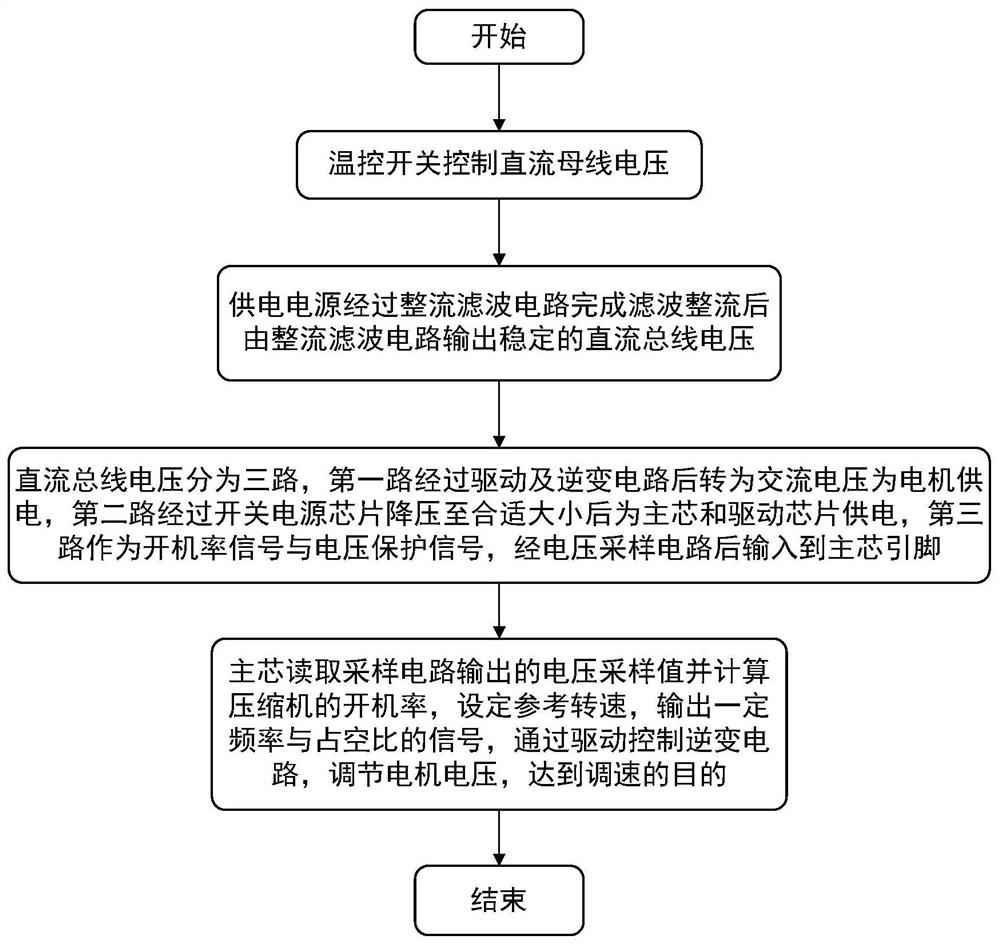

[0031] like figure 1 In the shown embodiment, it includes a power supply module 1 and a compressor module 11, the power supply module 1 is connected to the compressor module 11 to supply power for the compressor module 11, and the power supply module 1 includes an external AC power supply 101 for controlling the DC bus Voltage temperature control switch 102; the external AC power supply 101 includes two-phase output L phase and N phase, the connection terminals of the frequency converter include frequency converter connection terminal L and frequency converter connection terminal N, and the L phase circuit is connected in series with the temperature control switch 102 It is connected to the terminal L of the frequency converter, and the N-phase line is connected to the terminal N of the frequency converter. The temperature control switch 102 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com