Process for improving coloring rate of polyester printing

A printing and crafting technology, applied in the field of clothing fabrics, can solve the problems of inability to guarantee the printing coloring rate, affecting the health of users, and inability to accurately express the excellent effect of pretreatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

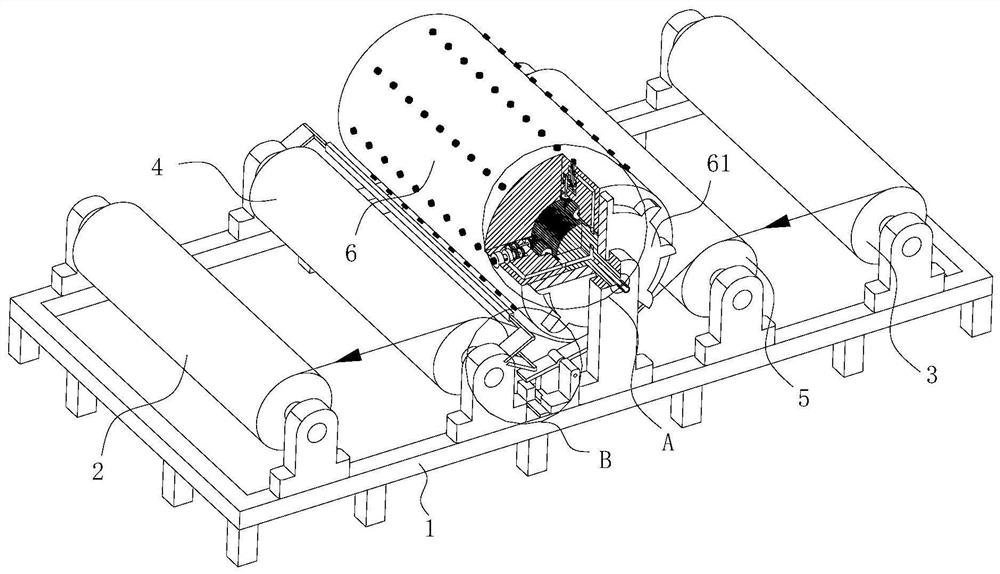

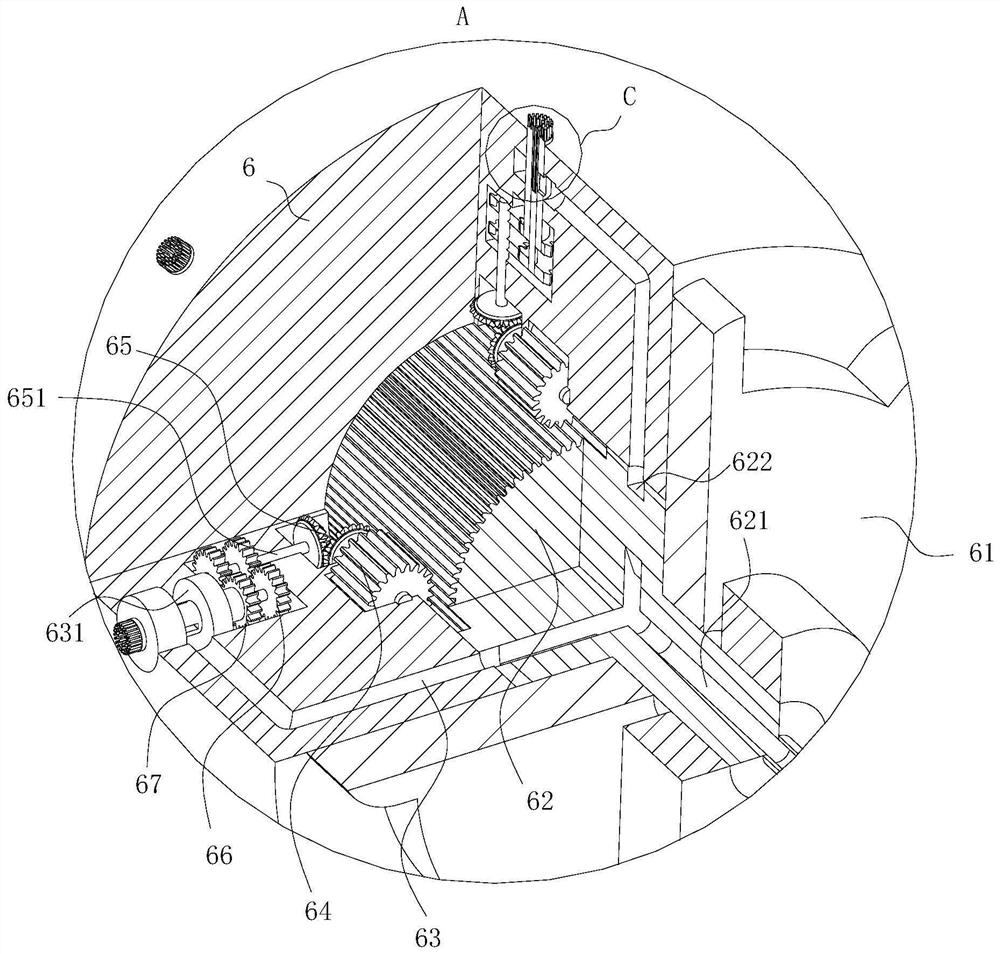

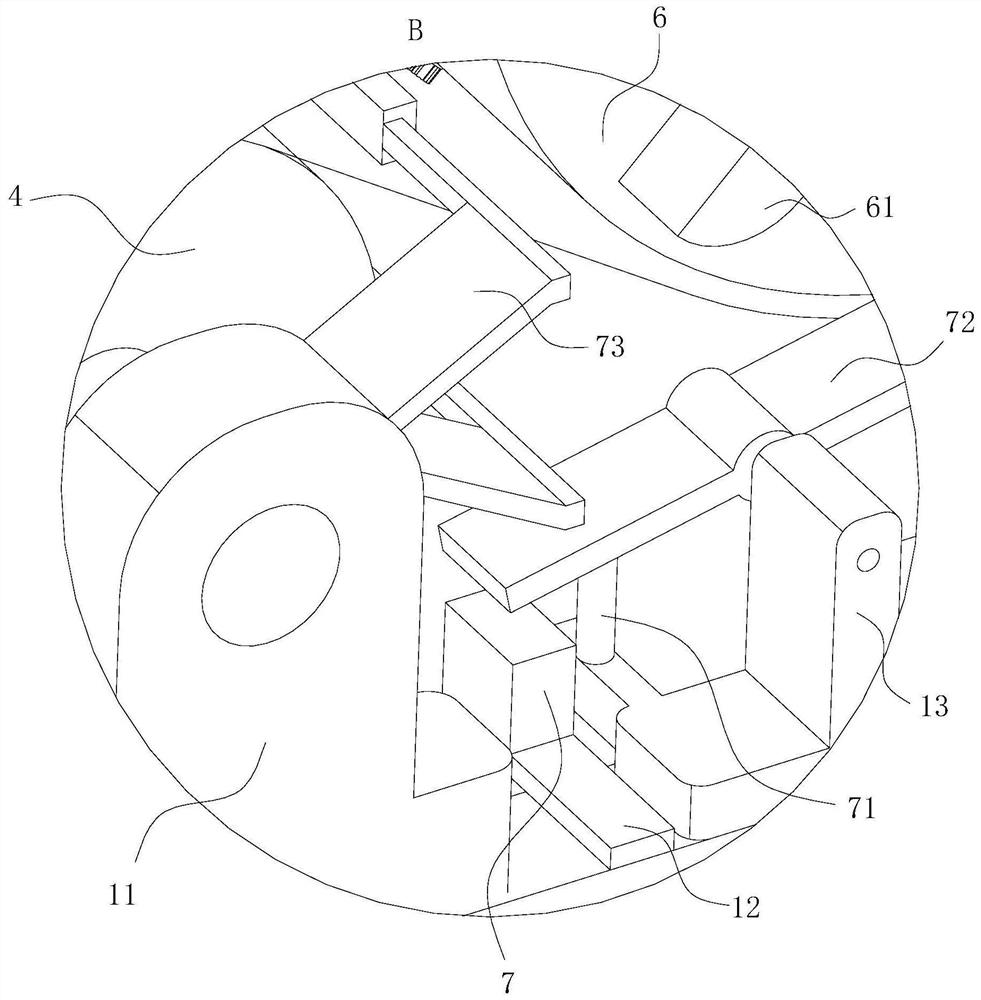

[0038] As an embodiment of the present invention, the sanding roller 6 is provided with a third installation cavity; the top end of the rotating shaft 651 is located in the third installation cavity; the first gear train 66 and the second gear train 67 are installed in the third installation The distance between the gear train one 66 and the top of the rotating shaft 651 is greater than the distance between the gear train two 67 and the rotating shaft 651 top; the transmission ratio between the gear train one 66 and the gear train two 67 is different; the gear train one 66 and gear train two 67 power all source and rotating shaft 651; The inside of described outer shaft 68 is equipped with inner shaft 681; The top of described inner shaft 681 exceeds the surface of sanding roller 6, becomes the sanding head; Both the lower ends of the shaft 68 and the inner shaft 681 are inserted into the installation cavity three; the outer shaft 68 is driven by the rotating shaft 651 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com