Twin-turbo control system and method

A technology of supercharging control and turbocharger, which is applied in electrical control, engine control, fuel injection control, etc., and can solve the problems of insufficient low-end torque and poor starting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

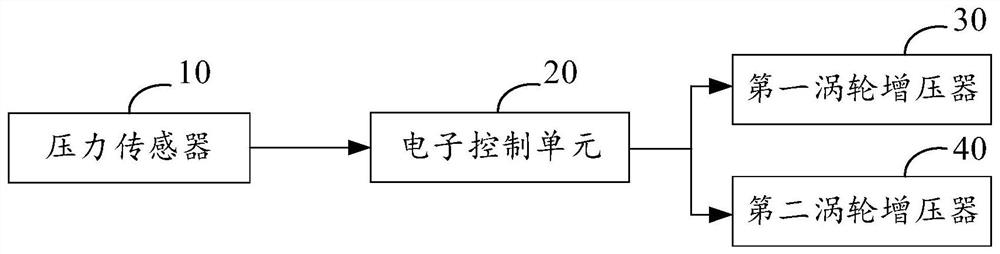

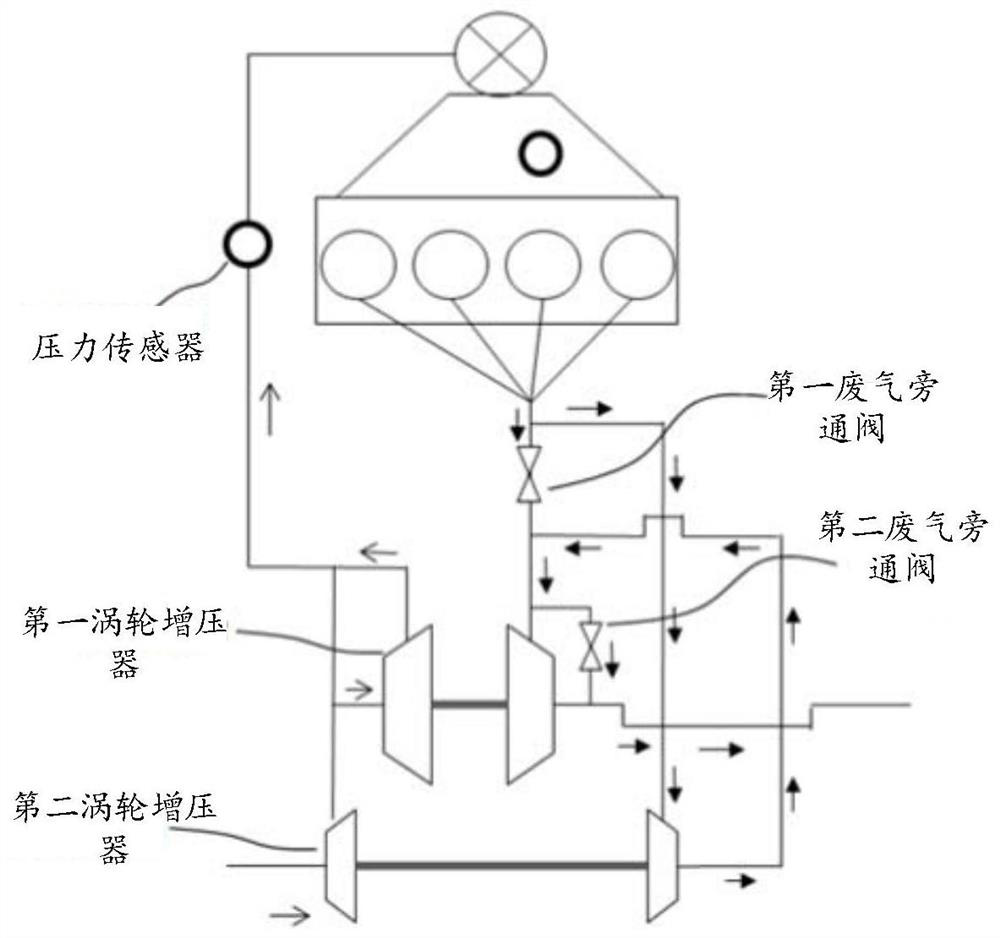

[0050] refer to figure 1 , figure 1It is a schematic diagram of the functional modules of the first embodiment of the twin turbocharger control system of the present invention. The twin turbocharger control system includes: a pressure sensor 10, an electronic control unit 20, a first turbocharger 30 and a second turbocharger 40, wherein the first turbocharger and the second turbocharger The turbocharger is arranged on the engine, and the pressure sensor is arranged in the intake pipe connected with the engine;

[0051] The pressure sensor 10 is used to detect the current pressure value in the intake pipe, and send the current pressure value to the electronic control unit. It should be noted that the pressure sensor may be a pressure temperature sensor or a general pressure sensor, which is not limited in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com