Damping support base for rail

A technology of rails and supports, applied in rails, roads, springs/shock absorbers, etc., can solve the influence of high frequency vibration reduction effect, the damping strength of dampers cannot be adjusted according to actual needs, and the vibration reduction effect is not satisfactory, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

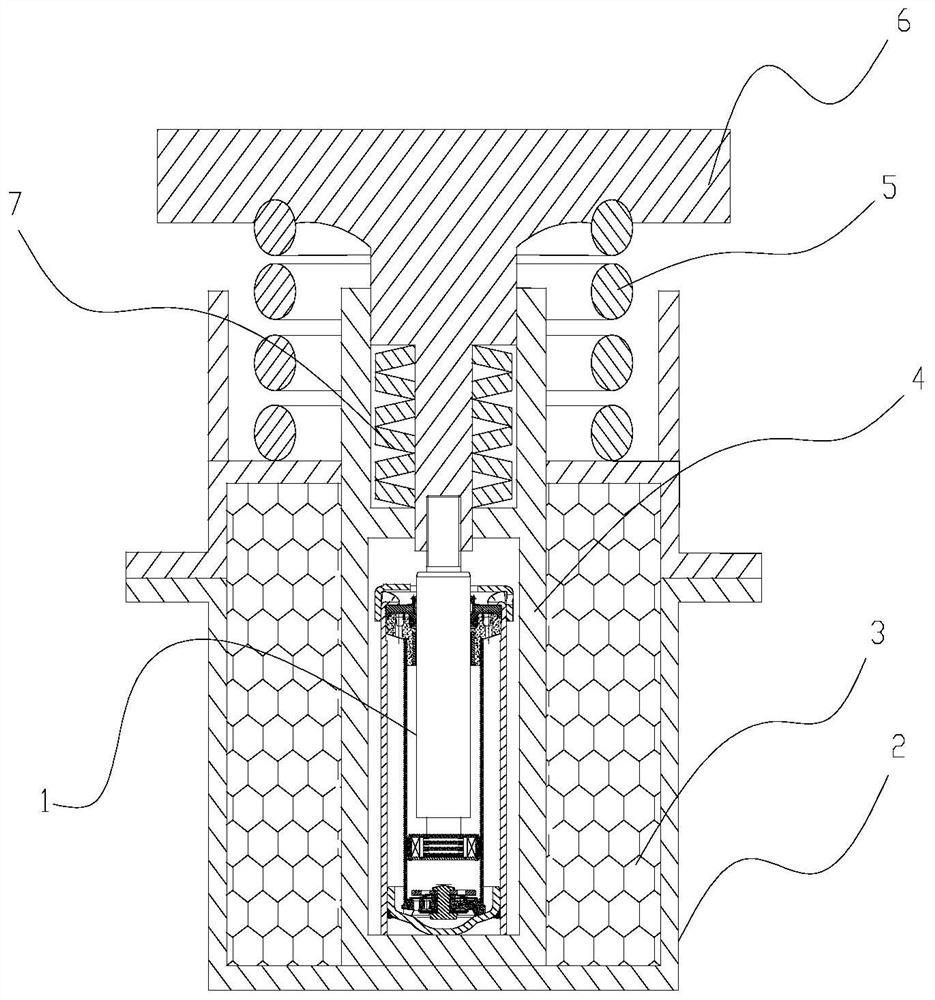

[0017] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the damping support for the track of this embodiment includes a base 2, a track support 6, and a damping spring supported between the base 2 and the track support 6 5 and a damper 1 arranged in the base 2 for damping the vibration of the track support 6;

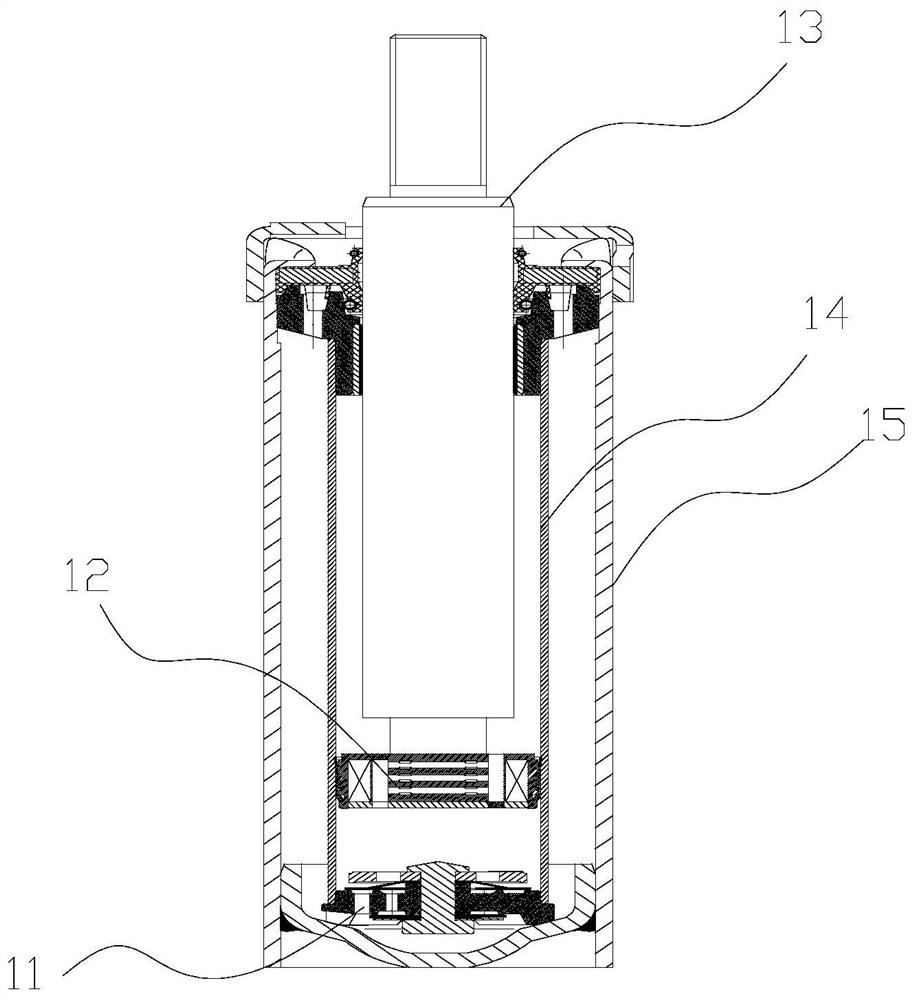

[0018] As shown in the figure, the base 2 includes a base with a height and foundation and a mounting cylinder 4 fixedly arranged in the base; the damping spring 5 is supported between the upper end of the base and the bottom of the track support 6; the mounting cylinder 4 The interior is divided into an upper cylinder and a lower cylinder by a partition in the middle; the damper 1 is fixedly installed in the lower cylinder; the rail support 6 is integrally formed with vertically arranged guide posts; the guide posts pass through The partition is connected to the piston rod 13 of the damper 1 .

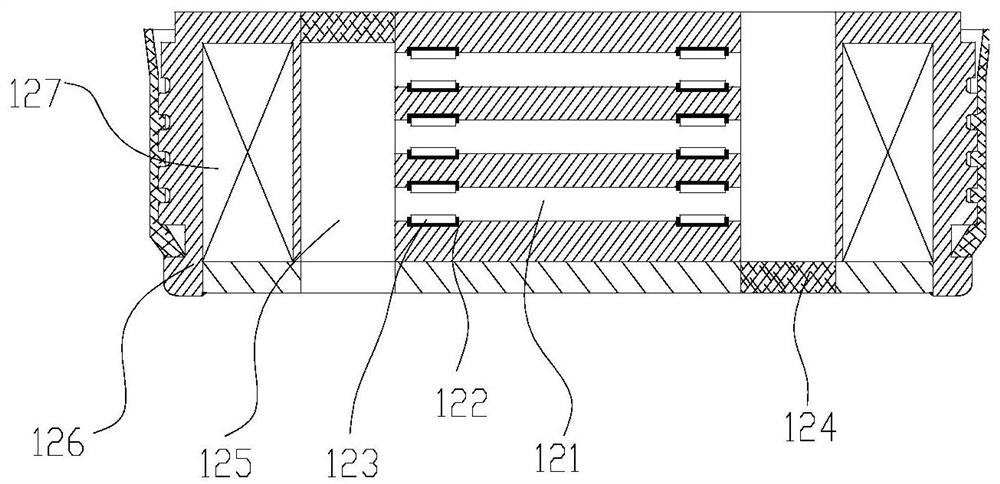

[0019] like figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com