Optical modulator based on coated black phosphorus micro-nano optical fiber roll-type resonator

A technology of micro-nano optical fiber and resonator, which is applied in the direction of cladding optical fiber, optical waveguide light guide, instrument, etc., which can solve the problems of poor mechanical stability, difficult practical application, and reduced evanescent field strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of black phosphorus deposited micro-nano optical fiber:

[0059] (1) Heat the ceramic microcouple heater to the operating temperature, which is about 1300 °C.

[0060] (2) Strip off the coating of a common single-mode optical fiber about 4 cm long, fix it on a micro-displacement platform (Newport, XML200), and place the stripped coating in the center of the ceramic microcouple heater.

[0061] (3) Start the LabVIEW program to control the movement of the micro-displacement platform to draw the fiber. By controlling the LabVIEW program, the fiber is tapered until the diameter of the cone waist is 2.35 μm.

[0062] (4) Remove the optical fiber, fix it on a clean low-refractive index plate that has been cleaned with alcohol, and use adhesive tape to fix the unstripped coating at both ends of the optical fiber.

[0063] (5) Connect one end of the fixed micro-nano fiber pigtail to the 980 nm laser, and the other end to the spectrometer. Turn on the laser and shi...

Embodiment 2

[0066] Preparation of low refractive index UV glue support rod:

[0067] Select a polymethylmethyl acetate (PMMA) rod with a length of about 2 cm and a diameter of 1 cm, and evenly wrap its surface with low-refractive-index UV glue, and cure it with a UV lamp (Hamamatsu, L9588-02A).

Embodiment 3

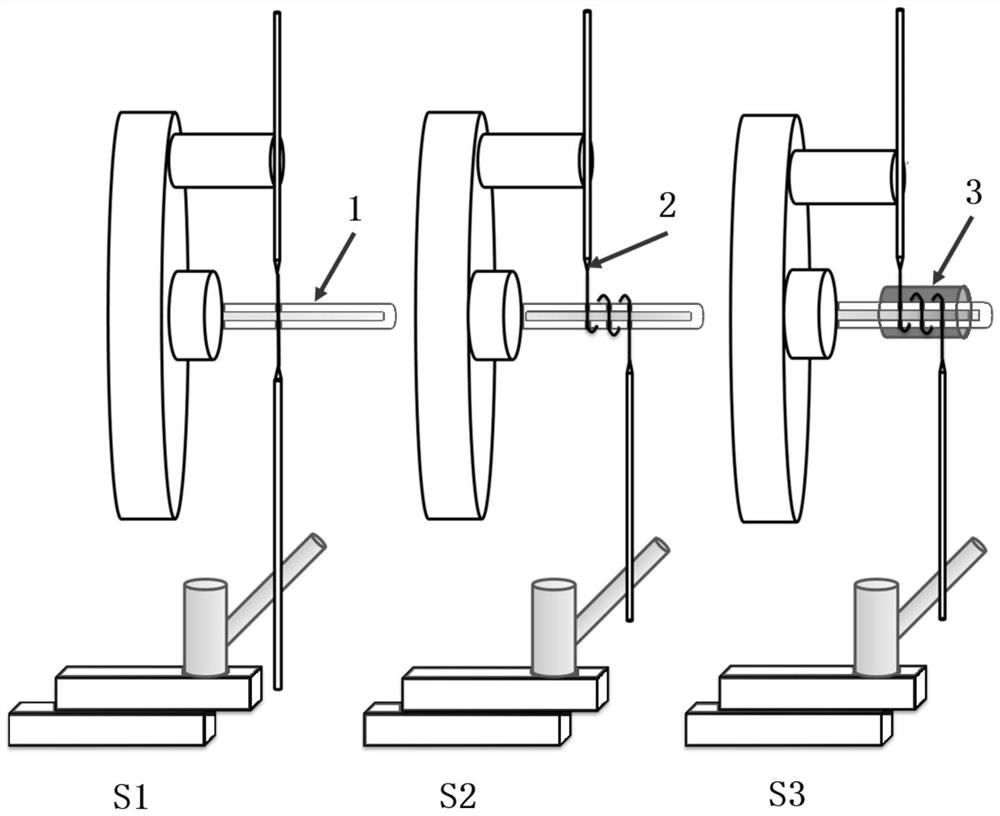

[0069] Fabrication of optical modulators based on coated black phosphorus micro-nano fiber coil resonators (such as figure 1 shown):

[0070] S1. Fix the low-refractive-index ultraviolet glue support rod 1 prepared in Example 2 on the center of the rotary controller (SMC100), fix the micro-nano optical fiber 2 produced in Example 1 on the rotary controller and at the same time place the cone waist part Riding on the support rod 1, one side of the optical fiber is fixed, and the other side falls vertically.

[0071] S2. Place the rotary controller on the micro-displacement platform (Newport, XML100) to control the rotation speed of the rotary controller and the speed of the micro-displacement platform. The rotation angle of the rotary controller is 1620 °, and the number of turns of the roll resonator is 4 turns.

[0072] S3. Coating the low-refractive-index polymer 3 on the periphery of the rolled resonator manufactured in step S2.

[0073] The optical modulator is composed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com