Mask alignment photoetching machine based on UV-LED area array type light source

A UV-LED, mask alignment technology, applied in the semiconductor field, can solve the problems of complex light source collimation optical path, increased cost, increased structural complexity of lithography machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described below with reference to the accompanying drawings. Those skilled in the art would recognize that the described embodiments can be modified in various ways or combinations thereof without departing from the spirit and scope of the invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

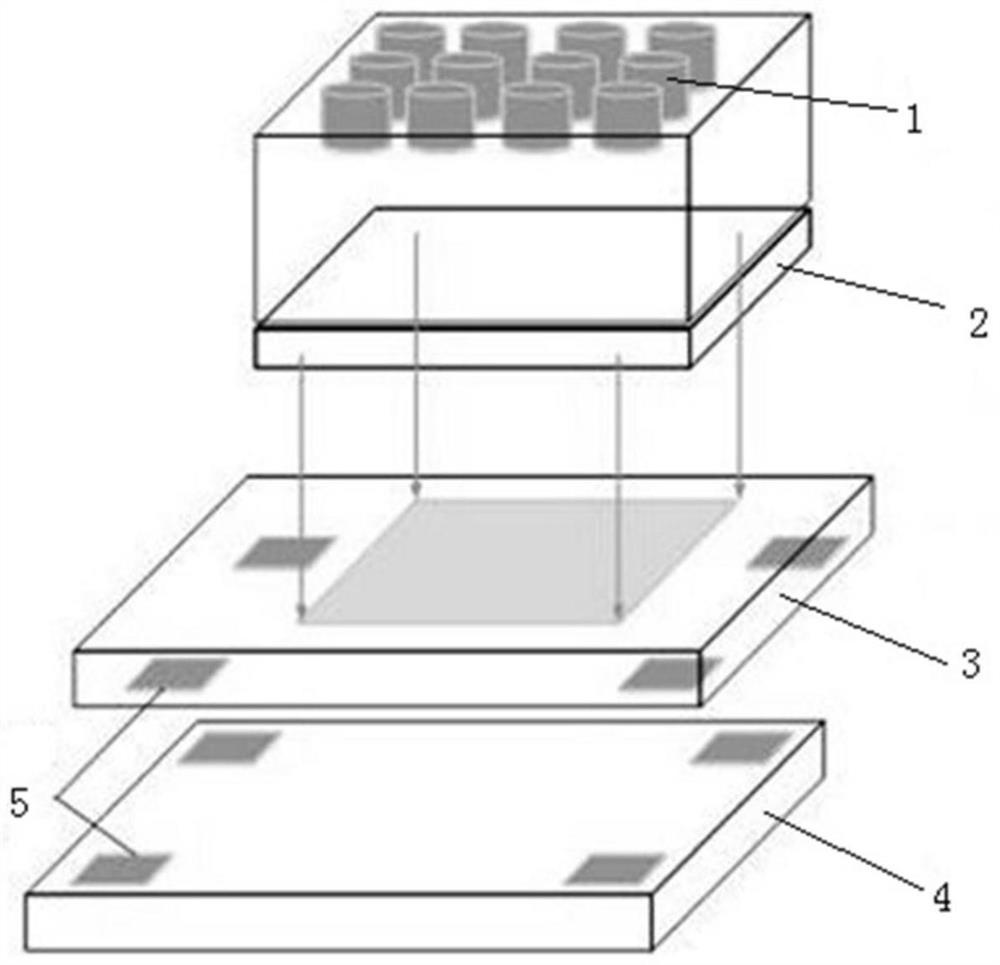

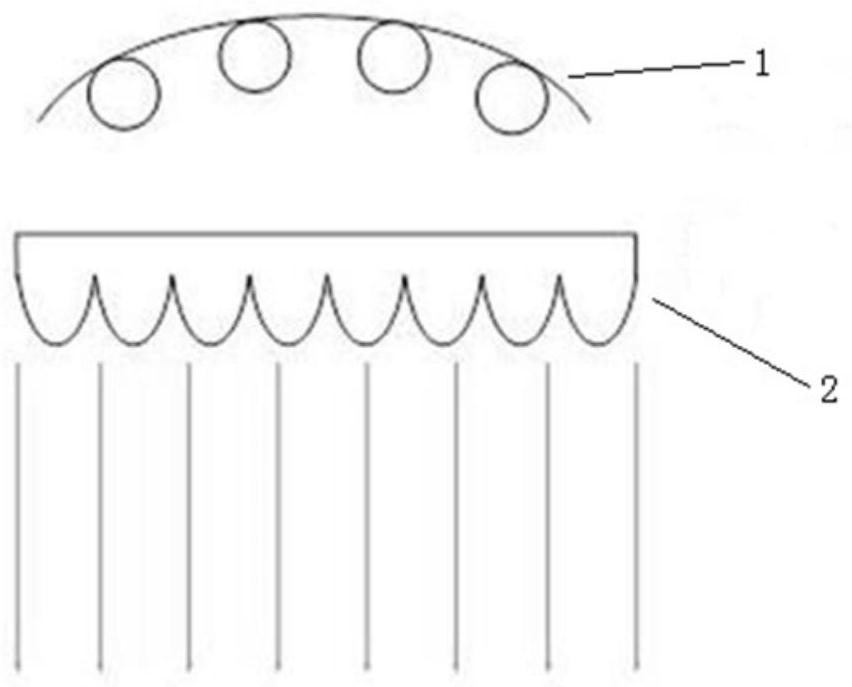

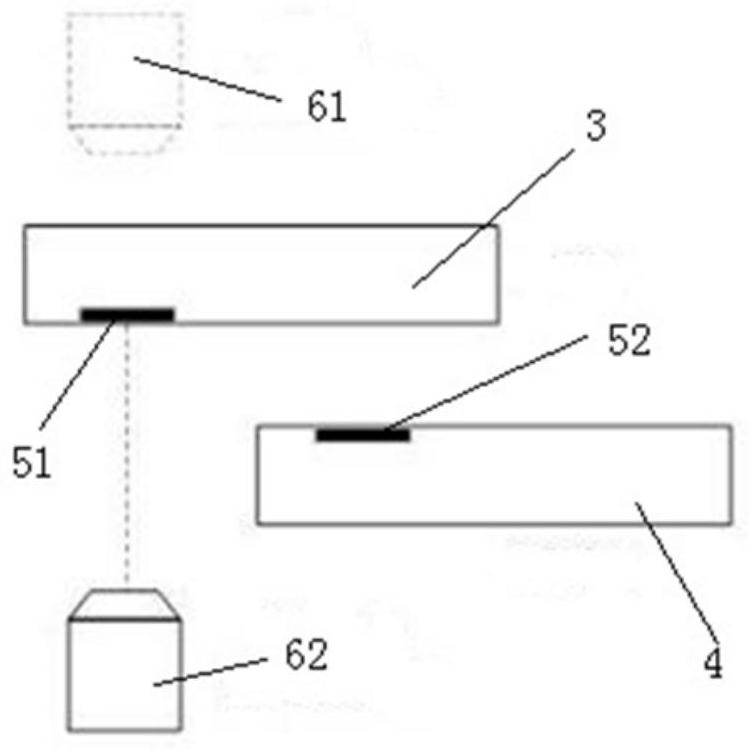

[0041] figure 1 is a structural schematic diagram of the mask alignment lithography machine of the present invention, figure 2 It is a schematic diagram of UV-LED light source and microlens array in the present invention, such as figure 1 with figure 2 As shown, the mask alignment lithography machine is a mask alignment lithography machine based on UV-LED area array light source, and its light source adopts UV-LED light source 1 to form an exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com