Heterojunction back contact solar cell and forming method thereof

A solar cell and heterojunction technology, applied in the field of solar cells, can solve the problems of complex patterning process and high battery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

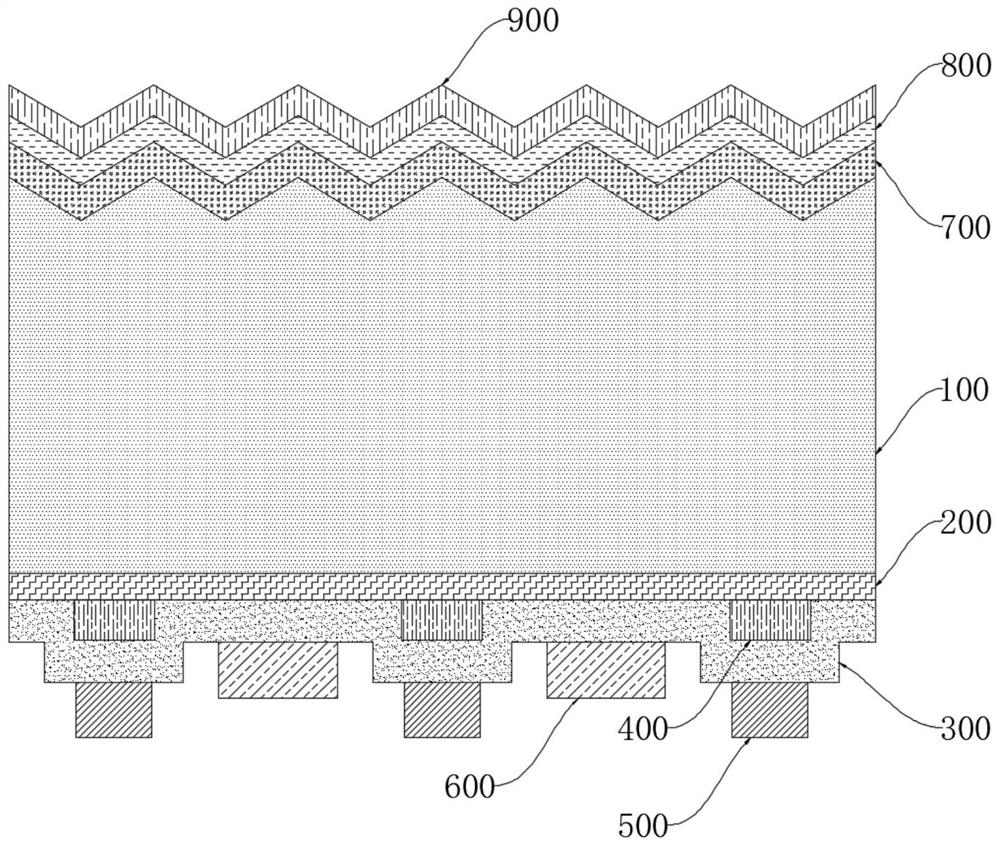

[0036] Such as figure 1 As shown, this embodiment can specifically provide a heterojunction back contact solar cell to solve at least one problem existing in the prior art. The heterojunction back contact solar cell may include but not limited to a semiconductor substrate 100, a first passivation layer 200, a P-type doped silicon film 300, an N-type doped silicon film 400, a first electrode 500 and a second electrode 600, front surface field 700, second passivation layer 800, anti-reflection layer 900 and so on.

[0037] The semiconductor substrate 100 has a front surface and a back surface. The front surface can be used to face the sun as a light-receiving surface to collect sunlight; the back surface can be used to place photovoltaic devices for photoelectric conversion. In some embodiments of the present invention, the front surface can be arranged facing upward, and a front surface composite layer is arranged on the front surface, and the front surface composite layer in...

Embodiment 2

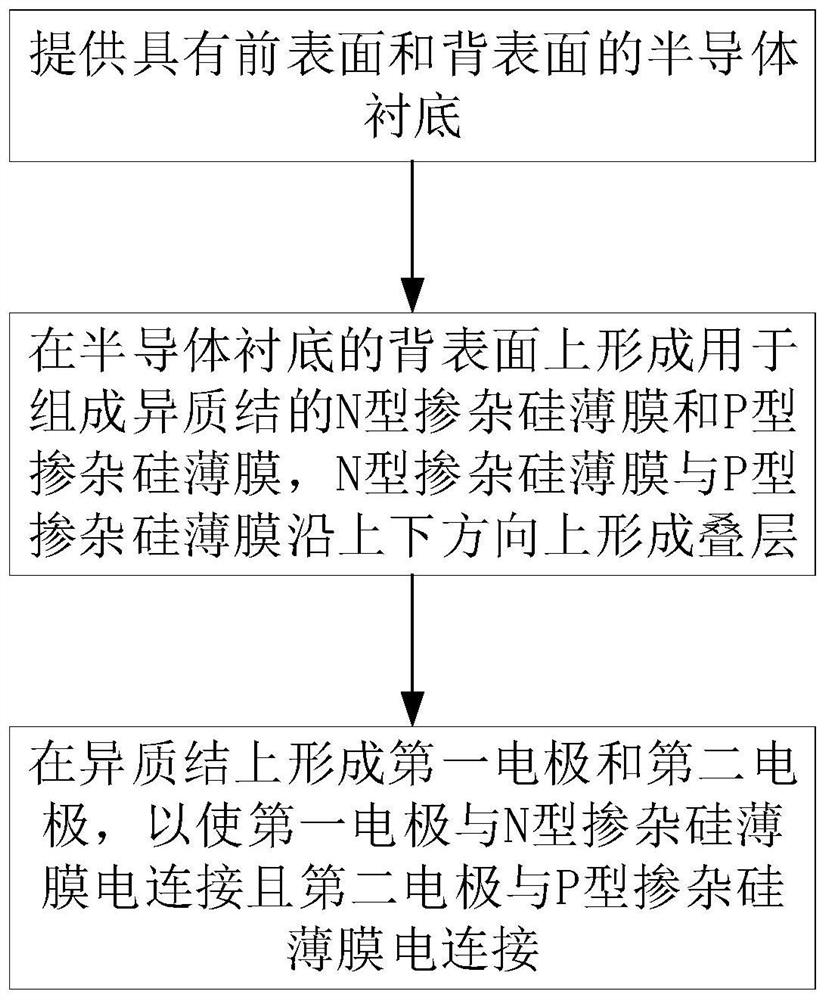

[0047] Based on the same inventive concept as the first embodiment, this embodiment provides a method for forming a heterojunction back contact solar cell, at least applicable to forming the structure of the heterojunction back contact solar cell in the first embodiment. By optimizing the growth process of the silicon thin film, the present invention can simplify the preparation process of the back pattern of the heterojunction back contact solar cell, and effectively reduce the preparation cost of the heterojunction back contact solar cell without reducing the conversion efficiency of the cell.

[0048] Such as figure 2 shown, and also see figure 1 , this embodiment provides a method for forming a heterojunction back contact solar cell, the method may include but not limited to the following steps.

[0049] A semiconductor substrate 100 is provided having a front surface and a back surface. The front surface is used to face the sun to collect sunlight; the back surface is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com