Millimeter wave broadband corrugated horn and manufacturing method thereof

A corrugated speaker and millimeter-wave technology, applied in the direction of waveguide speakers, radiation element structure, electrical components, etc., can solve the problems of high difficulty in processing ring loading grooves, affecting telecommunications performance, and easily generating high-order modes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

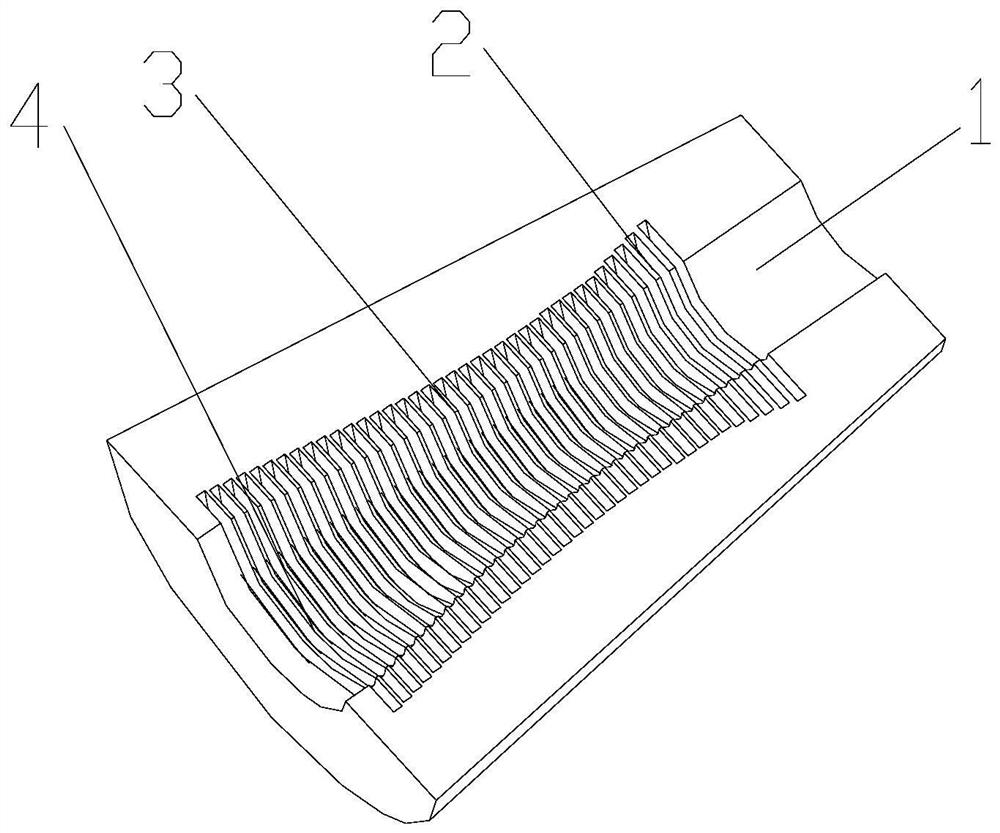

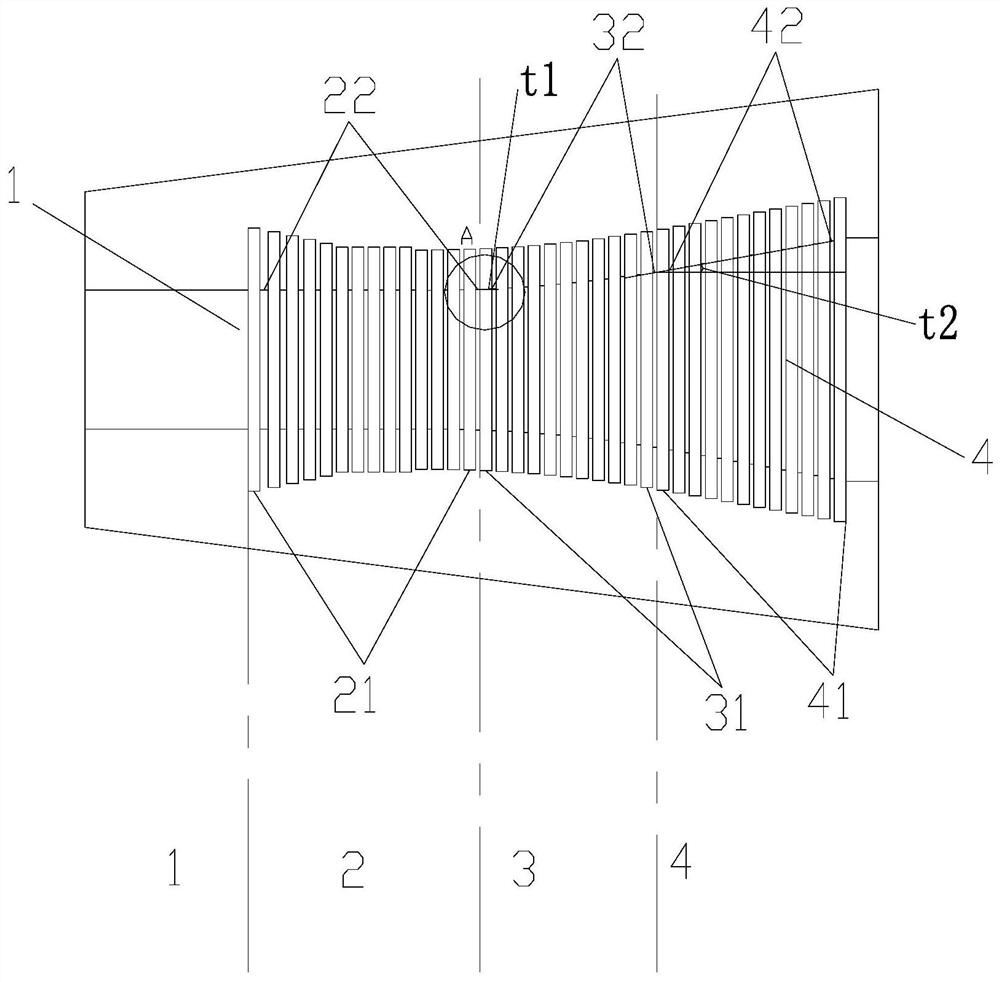

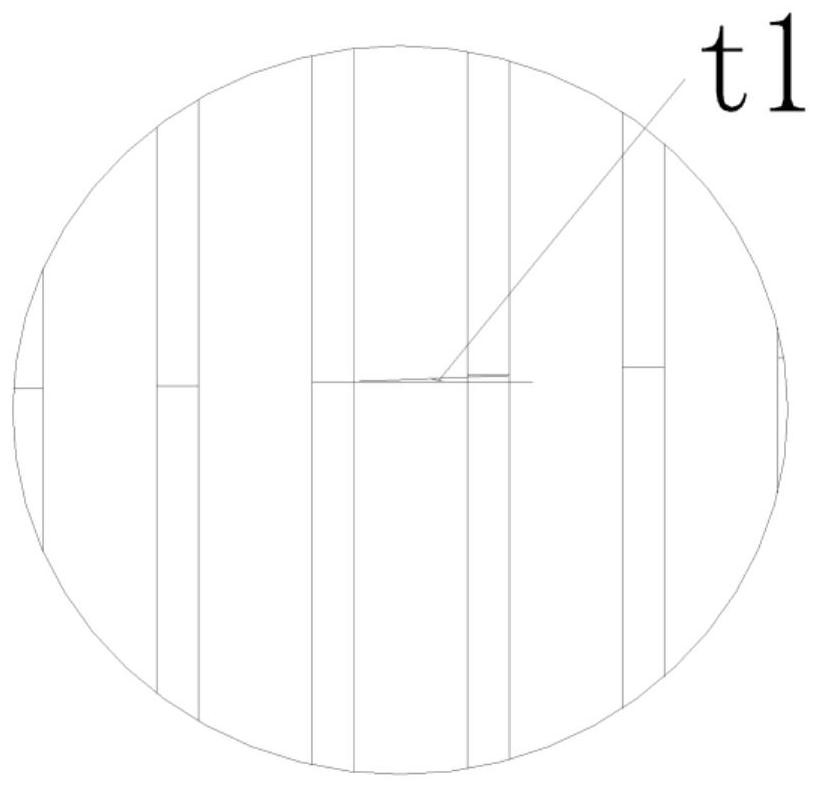

[0027] A millimeter-wave broadband corrugated horn, comprising a circular waveguide 1, a variable mode section 2, a variable angle section 3, and a radiation section 4, the circular waveguide 1 is a first optical wall waveguide, one end is a feed source input end, and the other end is connected to a transformer The inner wall of the mold section 2; the variable mode section 2 is composed of a second light wall waveguide 22 having the same diameter as the inner wall of the circular waveguide 1 and a periodic corrugated structure with gradual changes of several second corrugated grooves 21; the variable angle section 3 is composed of a linear tension The third optical wall waveguide 32 opened and several periodic third corrugated grooves 31 are formed, and the radiation section 4 is composed of a linearly expanded fourth optical wall waveguide 42 and several periodic fourth corrugated grooves 41 structures.

[0028] In the variable mode section 2 from the side close to the circul...

Embodiment 2

[0033] In order to manufacture the millimeter-wave broadband corrugated speaker of Example 1, the method disclosed in this example is to process the circular waveguide 1, the variable mode section 2, the variable angle section 3, and the radiation section 4 in sections, then tooling splicing, and finally welding as a whole .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com