Biomass water fertilizer production machine for agricultural planting and production method thereof

A biomass and production machine technology, applied in the direction of chemical instruments and methods, mixers, mixer accessories, etc., can solve problems such as uneven fertilization, large volume of biomass raw materials, manual labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

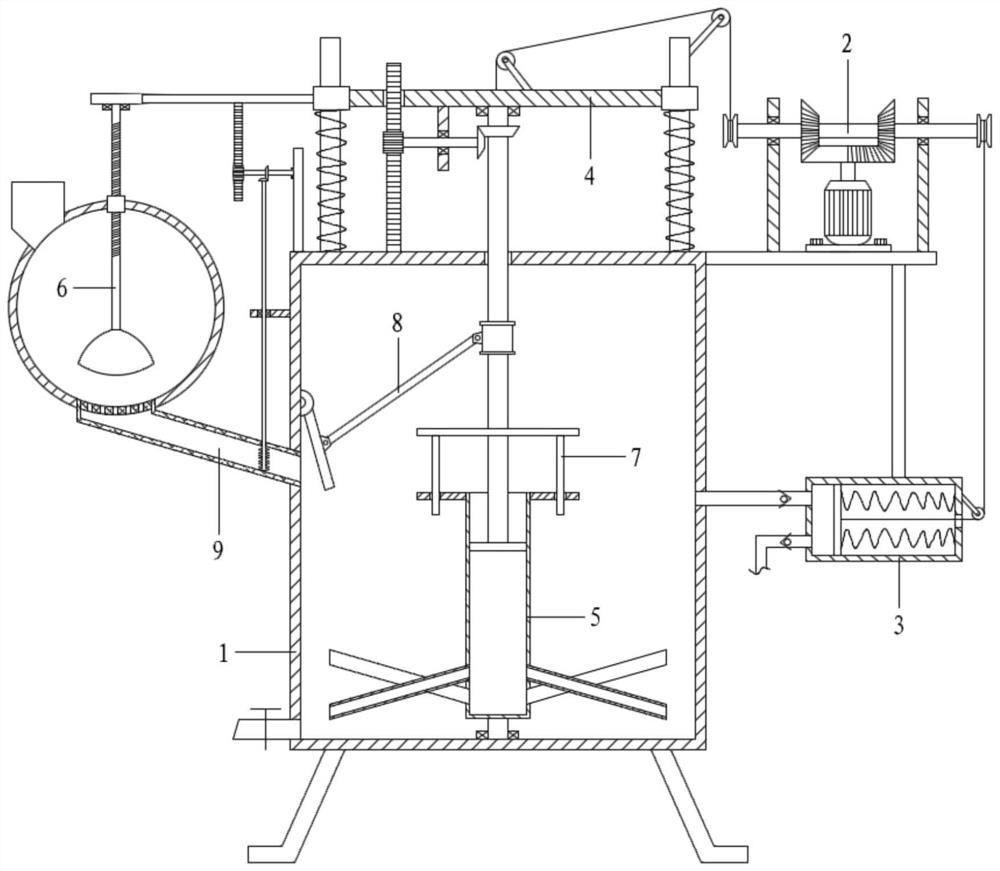

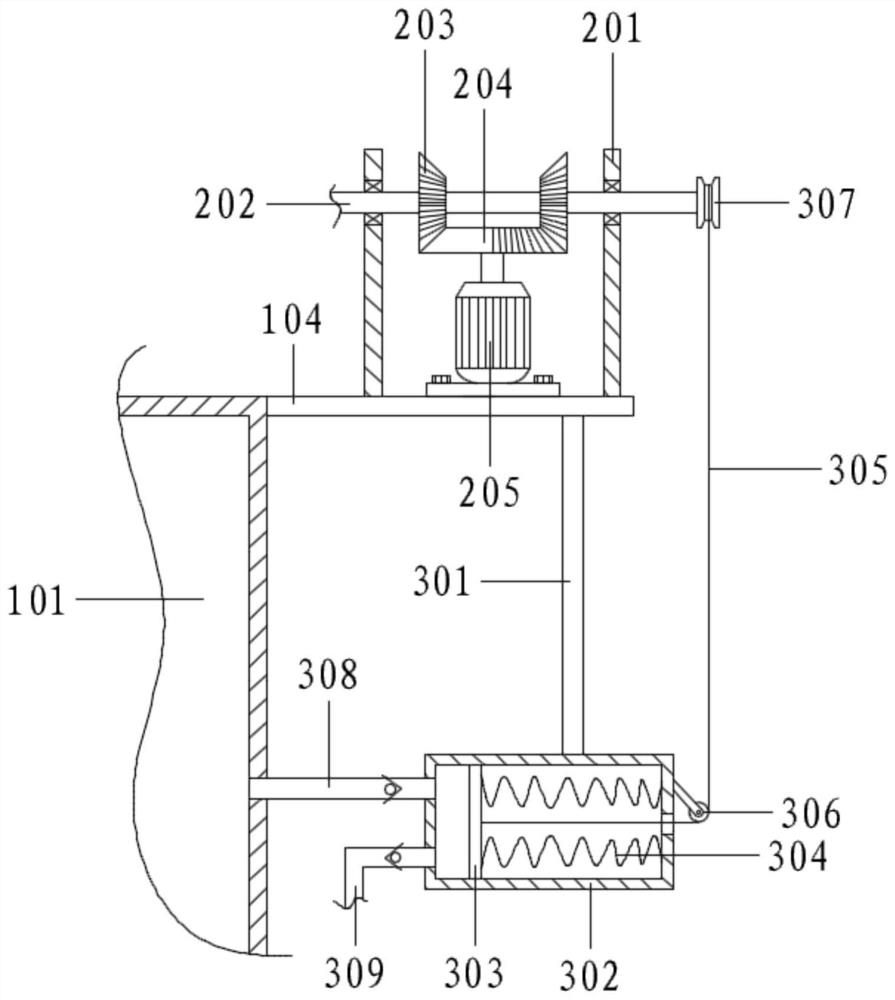

[0069] With reference to the accompanying drawings, a biomass water and fertilizer production machine for agricultural planting includes a tank assembly 1, a drive assembly 2, a water adding assembly 3, a lifting assembly 4, a piston assembly 5 and a crushing assembly 6;

[0070] The tank assembly 1 includes a preparation tank 101, a drain pipe 102, a foot 103, a type of support plate 104, a crushing box 105, a feed pipe 106 and a hopper 107; the bottom of the preparation tank 101 is connected with a drain pipe 102, and the drain A valve is installed on the pipe 102; a foot 103 is installed under the preparation tank 101; the middle part on the left side of the preparation tank 101 is connected with the bottom of the crushing box 105 through a feed pipe 106; the top of the crushing box 105 is connected with a feeding hopper 107; A type of support plate 104 is connected to the side, and a driving assembly 2 is arranged on the type of support plate 104; a water adding assembly 3 ...

Embodiment 2

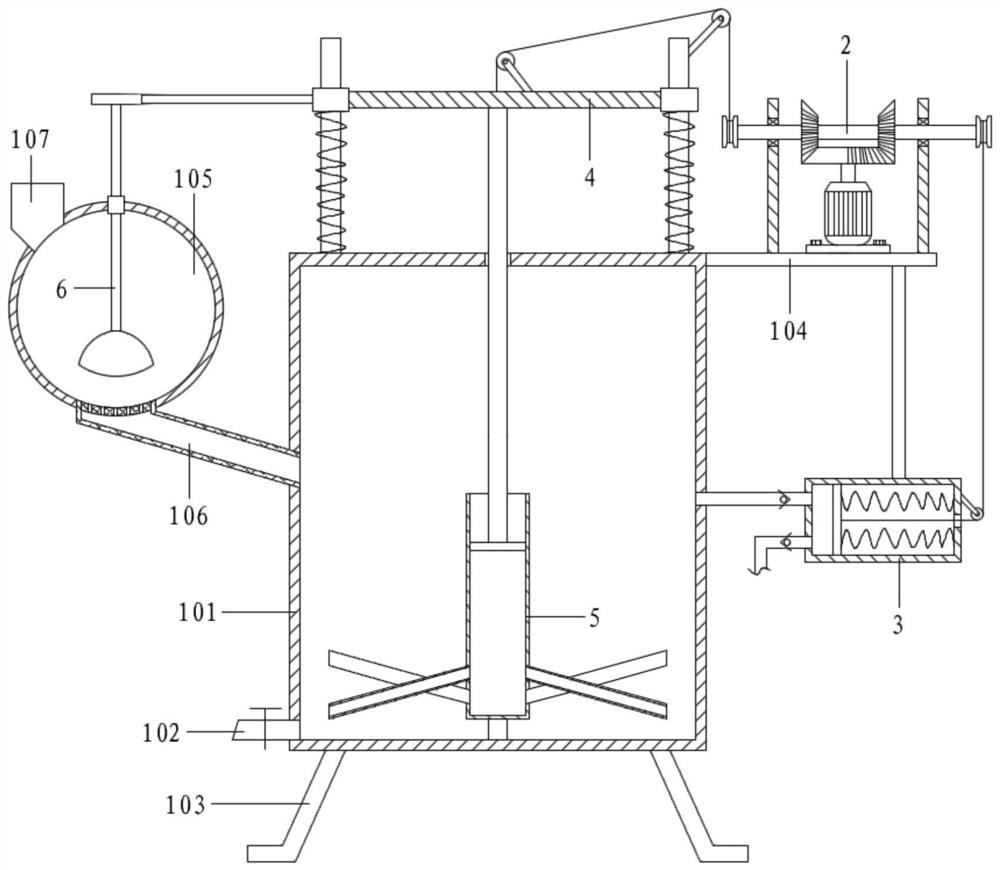

[0072] With reference to the accompanying drawings, a biomass water and fertilizer production machine for agricultural planting includes a tank assembly 1, a drive assembly 2, a water adding assembly 3, a lifting assembly 4, a piston assembly 5 and a crushing assembly 6;

[0073] The tank assembly 1 includes a preparation tank 101, a drain pipe 102, a foot 103, a type of support plate 104, a crushing box 105, a feed pipe 106 and a hopper 107; the bottom of the preparation tank 101 is connected with a drain pipe 102, and the drain A valve is installed on the pipe 102; a foot 103 is installed under the preparation tank 101; the middle part on the left side of the preparation tank 101 is connected with the bottom of the crushing box 105 through a feed pipe 106; the top of the crushing box 105 is connected with a feeding hopper 107; A type of support plate 104 is connected to the side, and a driving assembly 2 is arranged on the type of support plate 104; a water adding assembly 3 ...

Embodiment 3

[0096] The difference from Embodiment 2 is that in this embodiment, the crushing head 605 also rotates when it is raised and lowered, so that there is still a certain grinding effect on the biomass raw material to form powder.

[0097] The guide sleeve 604 is an internally threaded sleeve, and the pressure rod 603 is processed with external threads and is screwed with the guide sleeve 604; the top end of the pressure rod 603 is connected to the top plate 602 through bearing rotation.

[0098] Specifically, when the pressing rod 603 moves up and down, the pressing rod 603 itself rotates due to the action of the screw thread, thereby driving the crushing head 605 to rotate, crushing the biomass raw material and grinding at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com