High-frequency transmission composite copper foil substrate and preparation method

A copper foil substrate, high-frequency transmission technology, applied in the direction of circuit substrate materials, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as poor bonding force, increased copper production cost, and large signal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

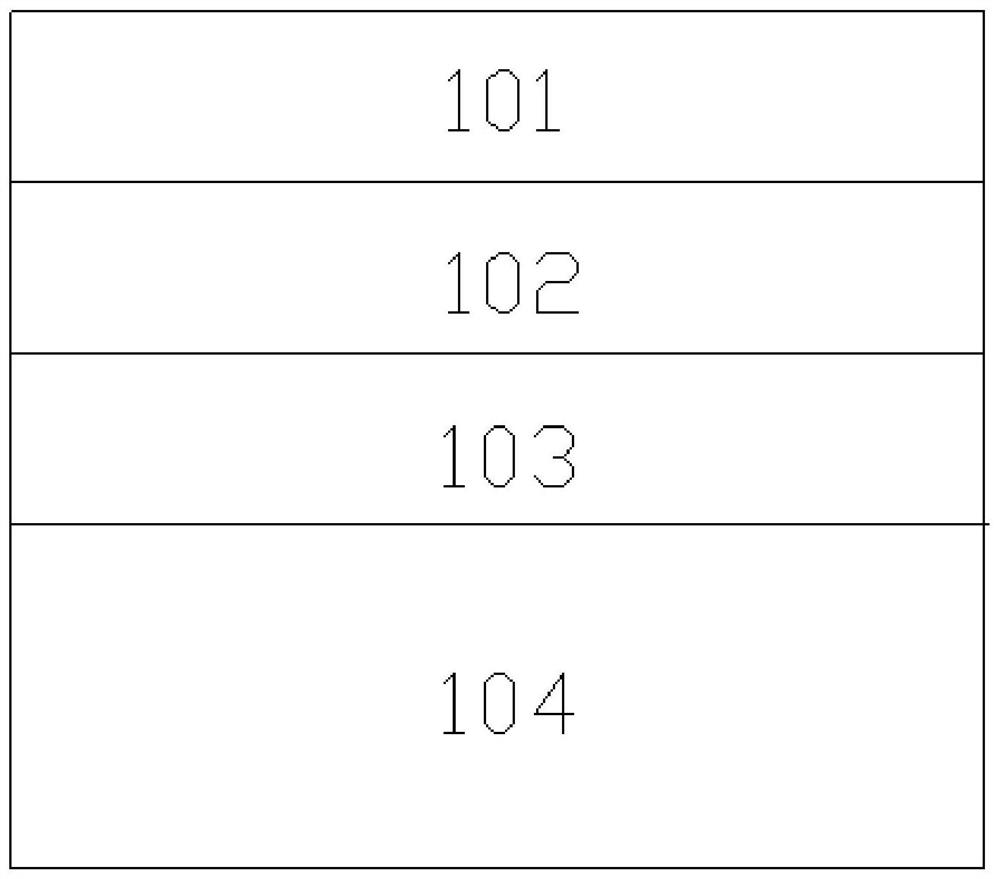

[0039] A method for preparing a high-frequency transmission composite copper foil substrate, comprising the following steps:

[0040] Step 1: providing a copper foil layer with a non-fluorine-modified polyimide layer, and coating a high-frequency insulating mixture on the non-fluorine-modified polyimide layer;

[0041] Step 2: After drying, a high-frequency insulating mixture layer of 6 μm to 25 μm is formed, and then a high-frequency polyimide layer is coated on the high-frequency insulating mixture layer to obtain a single-sided copper foil substrate;

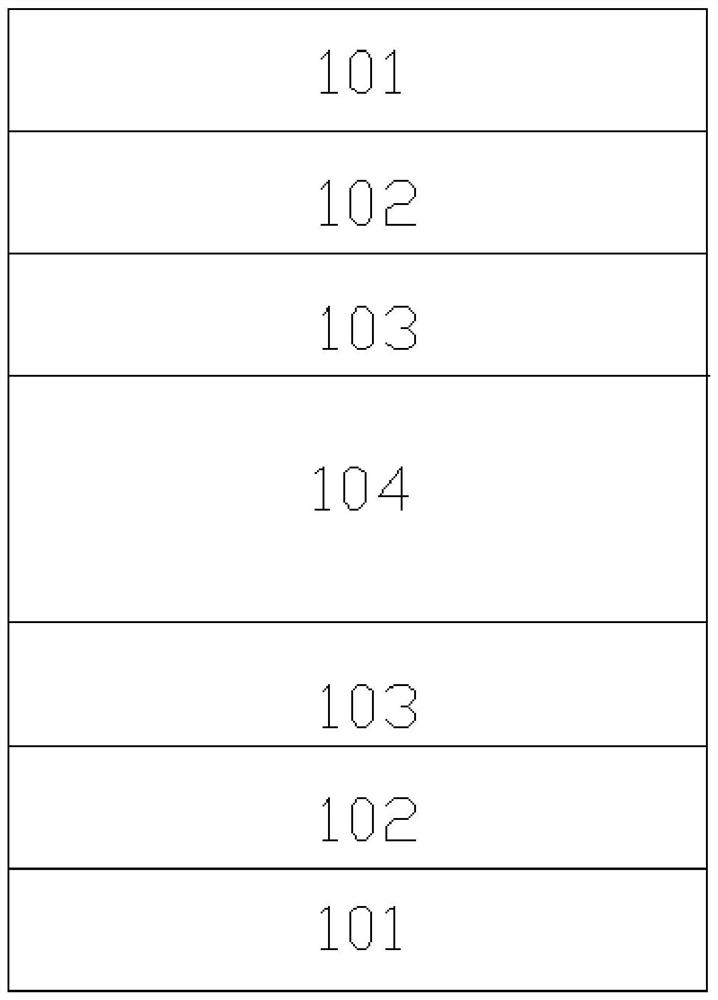

[0042] Step 3: Coating a high-frequency insulating mixture on the high-frequency polyimide layer of the single-sided copper foil substrate, and forming a high-frequency insulating mixture layer of 6 μm to 25 μm after drying;

[0043] Step 4: Laminate another copper foil layer with a non-fluorine-modified polyimide layer on the high-frequency insulating mixture layer, and form a tightly bonded double-sided copper foil through ...

Embodiment

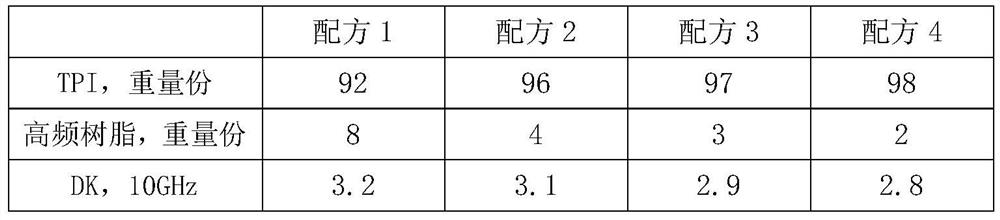

[0051] Embodiment: below are concrete embodiment of the present invention and comparative example, and test result thereof, see table 2 and table 3:

[0052] Table 2:

[0053]

[0054] table 3:

[0055]

[0056] Embodiments 2, 4, 7, 8, and 10 are single-sided copper foil substrates, and the preparation method is as follows:

[0057] Step 1: providing a copper foil layer with a non-fluorine-modified polyimide layer, and coating a high-frequency insulating mixture on the non-fluorine-modified polyimide layer;

[0058] Step 2: After drying, a high-frequency insulating mixture layer is formed, and then a high-frequency polyimide layer is coated on the high-frequency insulating mixture layer to obtain a single-sided copper foil substrate;

[0059] Wherein the thickness of the copper foil in Examples 2, 4, 7, 8, and 10 is 12 μm.

[0060] Embodiments 1, 3, 5, 6, and 9 are double-sided copper foil substrates, and the preparation method is as follows:

[0061] Step 1: providi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com