Slag-based road grouting material and preparation method thereof

A technology of grouting material and slag-based, which is applied in the field of road grouting material and its preparation, slag-based road grouting material and its preparation, and can solve the problems of poor stability, not dense slurry, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing slag-based road pressure slurry, comprising the following steps:

[0036] (1) Accurately weigh the gelling material and the admixture of the prescribed amount according to the proportioning in Table 1;

[0037] (2) Mix the materials evenly and add them to the slurry mixing pot together with water, adjust the slurry mixer at a speed of 700r / min, stir for 1min, then adjust the speed to 3000r / min, and stir for 3min.

[0038] (3) Use the press slurry flow cone funnel to measure the initial, 30min, and 60min fluidity of the press slurry, put the evenly stirred press slurry into a standard triple test mold of 40*40*160 evenly coated with butter, and vibrate evenly , and smooth out;

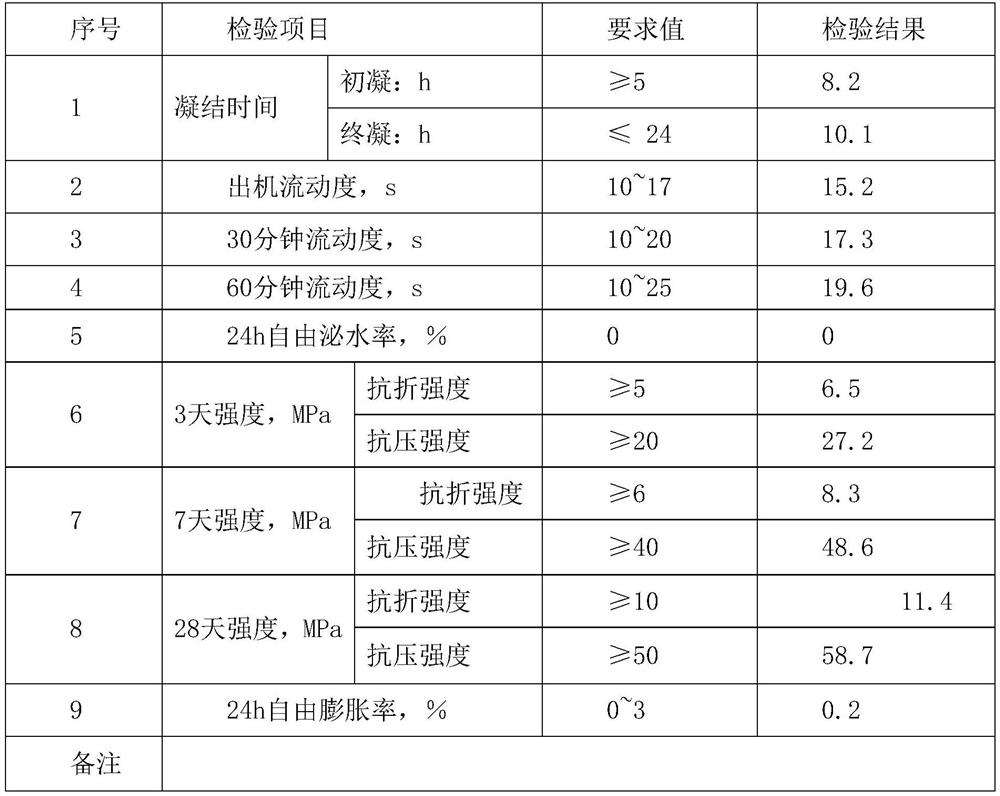

[0039] (4) Leave the mold at room temperature for 24 hours, put it into a standard constant temperature curing box, and cure it for 3 days, 7 days, and 28 days respectively, and test the flexural strength and compressive strength. The fluidity, flexural strength, compress...

Embodiment 2

[0045] A method for preparing slag-based road pressure slurry, comprising the following steps:

[0046] (1) Accurately weigh the gelling material and admixture of the specified amount according to the proportioning in Table 3;

[0047] (2) Mix the materials evenly and add them to the slurry mixing pot together with water, adjust the slurry mixer at a speed of 700r / min, stir for 1min, then adjust the speed to 3000r / min, and stir for 3min.

[0048] (3) Use the press slurry flow cone funnel to measure the initial, 30min, and 60min fluidity of the press slurry, put the evenly stirred press slurry into a standard triple test mold of 40*40*160 evenly coated with butter, and vibrate evenly , and smooth out;

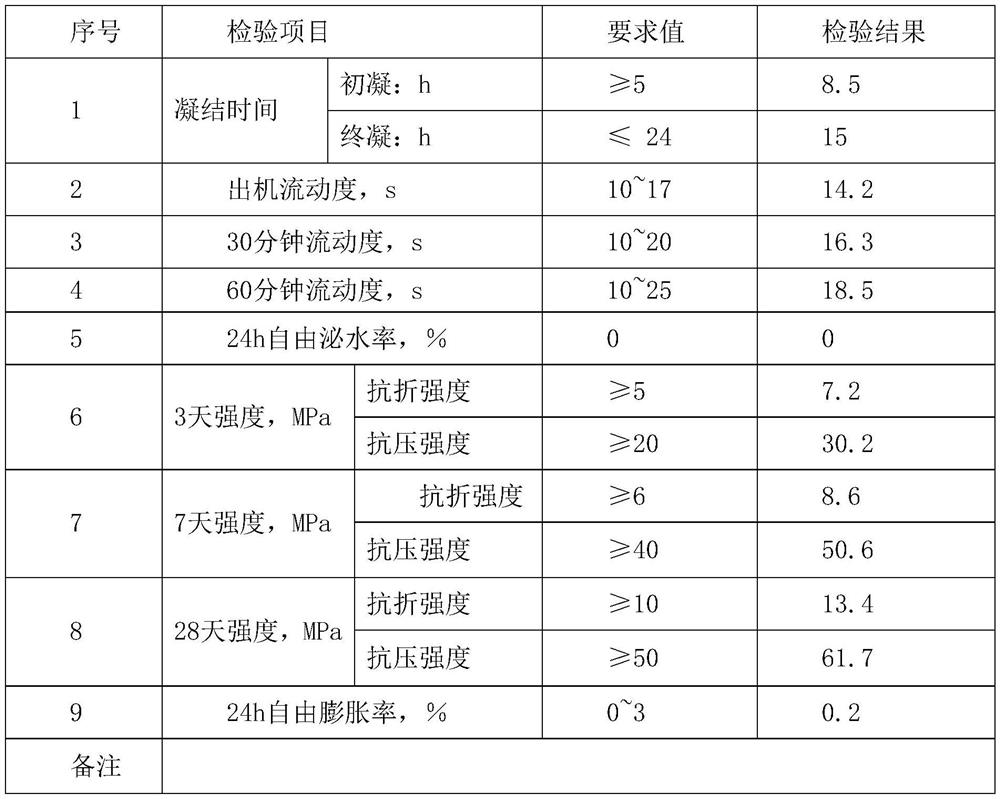

[0049] (4) Leave the mold at room temperature for 24 hours, put it into a standard constant temperature curing box, and cure it for 3 days, 7 days, and 28 days respectively, and test the flexural strength and compressive strength. The fluidity, flexural strength, compressive s...

Embodiment 3

[0056] A method for preparing slag-based road pressure slurry, comprising the following steps:

[0057] (1) Accurately weigh the gelling material and the admixture of the prescribed amount according to the proportioning in Table 5;

[0058](2) Mix the materials evenly and add them to the slurry mixing pot together with water, adjust the slurry mixer at a speed of 700r / min, stir for 1min, then adjust the speed to 3000r / min, and stir for 3min.

[0059] (3) Use the press slurry flow cone funnel to measure the initial, 30min, and 60min fluidity of the press slurry, put the evenly stirred press slurry into a standard triple test mold of 40*40*160 evenly coated with butter, and vibrate evenly , and smooth out;

[0060] (4) Leave the mold at room temperature for 24 hours, put it into a standard constant temperature curing box, and cure it for 3 days, 7 days, and 28 days respectively, and test the flexural strength and compressive strength. The fluidity, flexural strength, compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com