Preparation method of isoprene-based isopentenyl ether

A prenyl isopentenyl ether and inhibitor technology, applied in ether preparation, organic compound preparation, separation methods, etc., can solve the accumulation of heavy components, affect the yield of citral, and affect the long cycle of the device Operation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

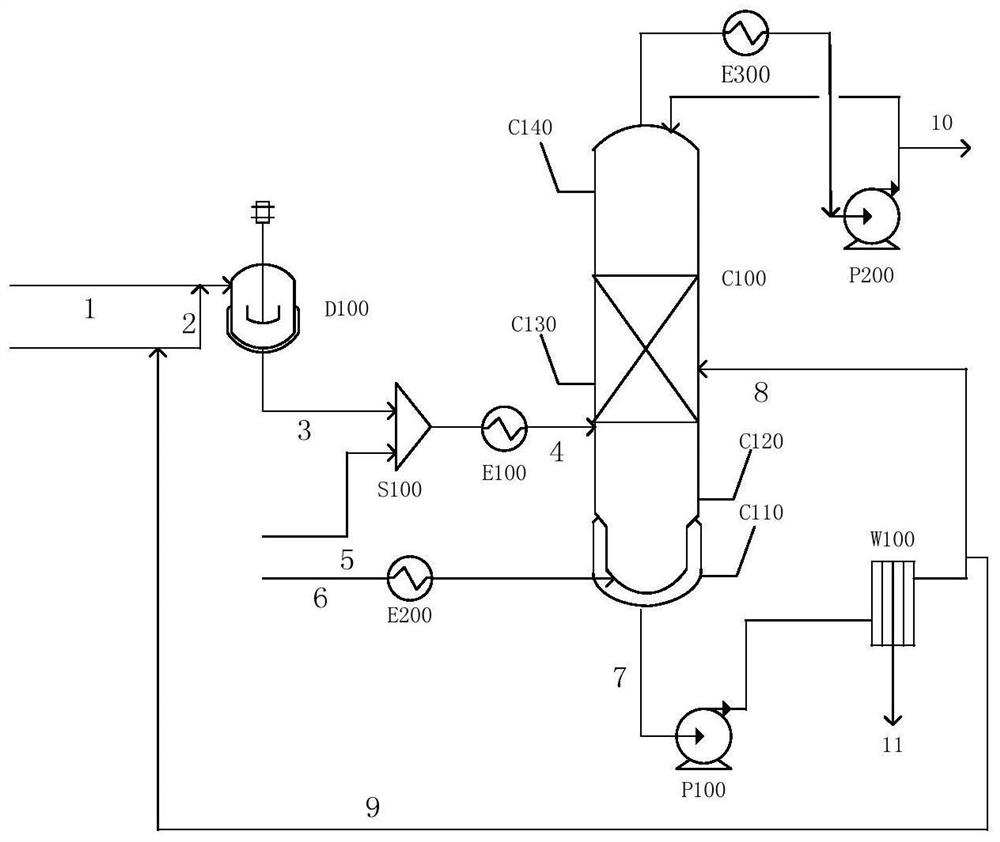

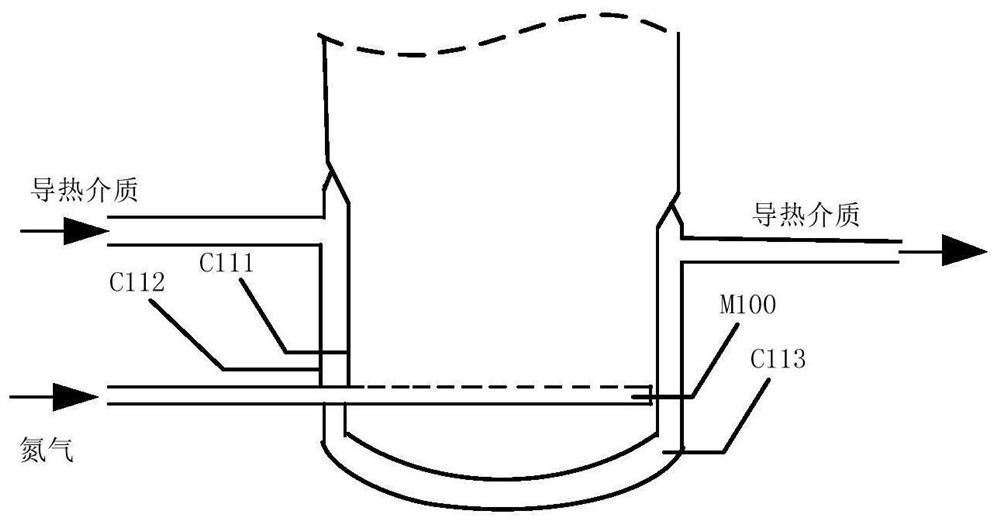

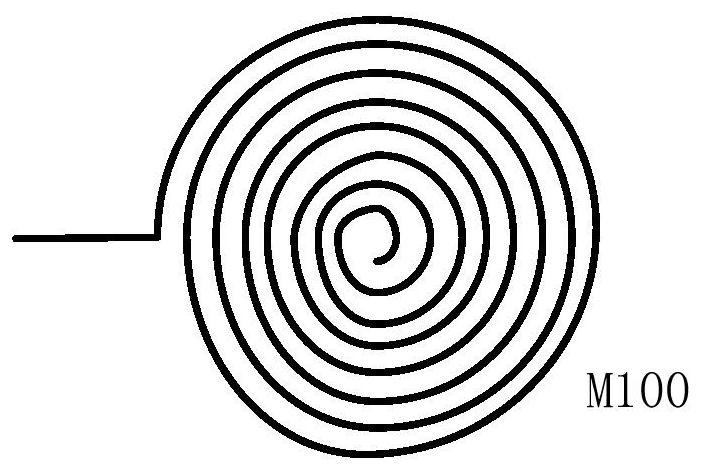

Embodiment 1

[0063] The size of the air outlet M130 of the nitrogen mixing device M100 is 5mm, ɑ is 45°, the distance between the air outlets M130 is 15cm, the direction of the air outlets of adjacent coils is opposite, and the distance between the coils is 10cm. The outlet distance is 20cm. The inner diameter of the column in the rectification zone C130 is 300mm. The rectification zone C130 is equipped with Raschig ring packing, the number of theoretical plates is 30, and the diameter of the reduced diameter section is 180mm. The feed inlet is located between the stripping zone C120 and the rectification zone C130, and there are 7 sieve trays below the feed inlet. The circulating liquid return port is located at the 10th theoretical plate from bottom to top in the rectification zone C130. Heat the nitrogen flow 6 to 80°C and introduce it into the nitrogen mixing device M100 at the bottom of the rectification tower C100. The nitrogen flow rate is 3m / s. After the nitrogen flow is stable, s...

Embodiment 2

[0065] The size of the air outlet M130 of the nitrogen mixing device M100 is 1mm, ɑ is 35°, and the distance between the air outlets M130 is 5cm. The outlet spacing is 30cm. The inner diameter of the column in the rectification zone C130 is 300mm. The rectification zone C130 is equipped with Raschig ring packing, the number of theoretical plates is 15, and the diameter of the reduced diameter section is 250mm. The feed inlet is located between the stripping zone C120 and the rectification zone C130, and there are 7 sieve trays below the feed inlet. The circulating liquid return port is located at the 5th theoretical plate from bottom to top in the rectification zone C130. Heat the nitrogen flow 6 to 130°C and introduce it into the nitrogen mixing device M100 at the bottom of the rectification tower C100. The nitrogen flow rate is 5m / s. After the nitrogen flow is stable, start the vacuum unit to reduce the pressure inside the rectification tower C100 to 10kPa (A), the tempera...

Embodiment 3

[0067]The size of the air outlet M130 of the nitrogen mixing device M100 is 0.03mm, ɑ is 75°, the distance between the air outlets M130 is 2cm, the direction of the air outlets of adjacent coils is opposite, and the distance between the coils is 15cm. The distance between the liquid outlets is 50cm. The inner diameter of the column in the rectification zone C130 is 300mm. The rectification zone C130 is equipped with Raschig ring packing, the number of theoretical plates is 10, and the diameter of the reduced diameter section is 200mm. The feed inlet is located between the stripping zone C120 and the rectification zone C130, and there are 30 sieve trays below the feed inlet. The circulating liquid return port is located at the 7th theoretical plate from bottom to top in the rectification zone C130. Heat the nitrogen stream 6 to 180°C and introduce it into the nitrogen mixing device M100 at the bottom of the rectification tower C100. The nitrogen flow rate is 10m / s. After the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com