Diamond composite material, as well as preparation method and application thereof

A composite material and diamond technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of weak bonding between diamond and cemented carbide, and poor durability of polycrystalline diamond composite sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

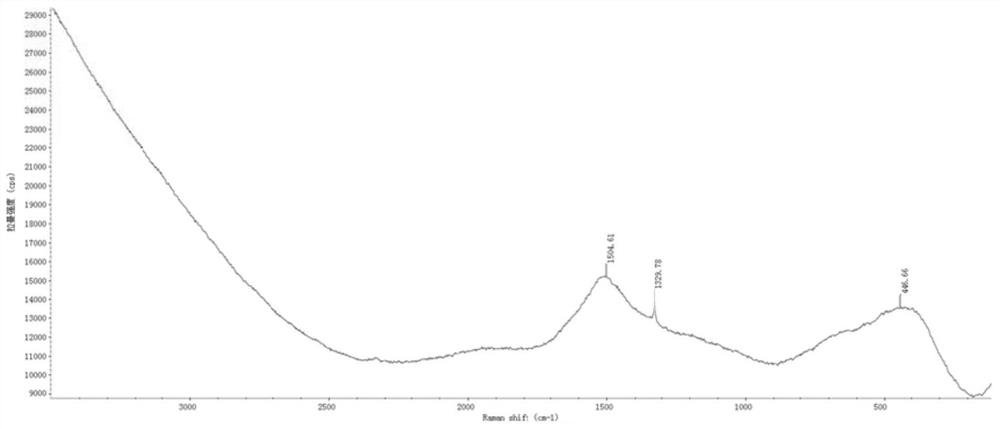

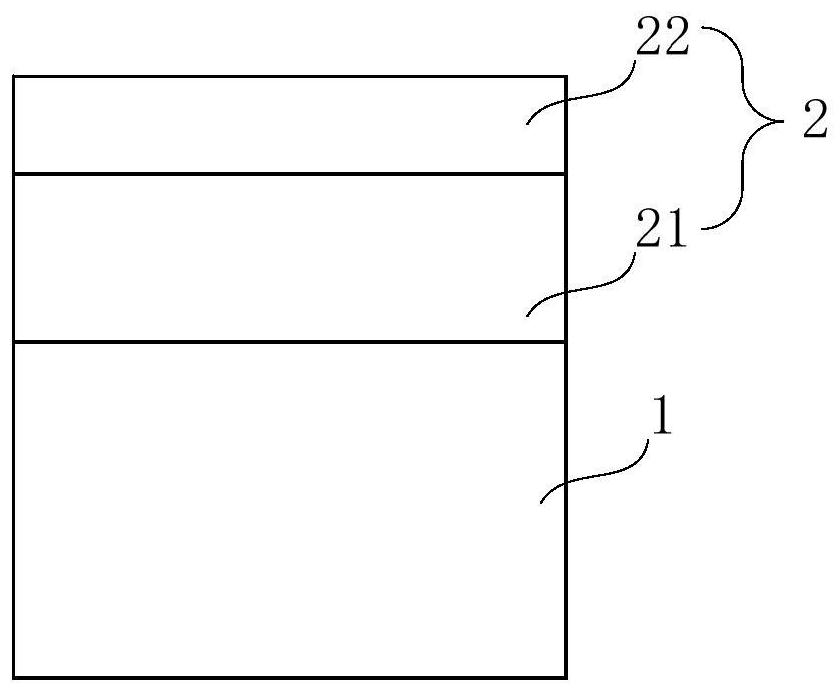

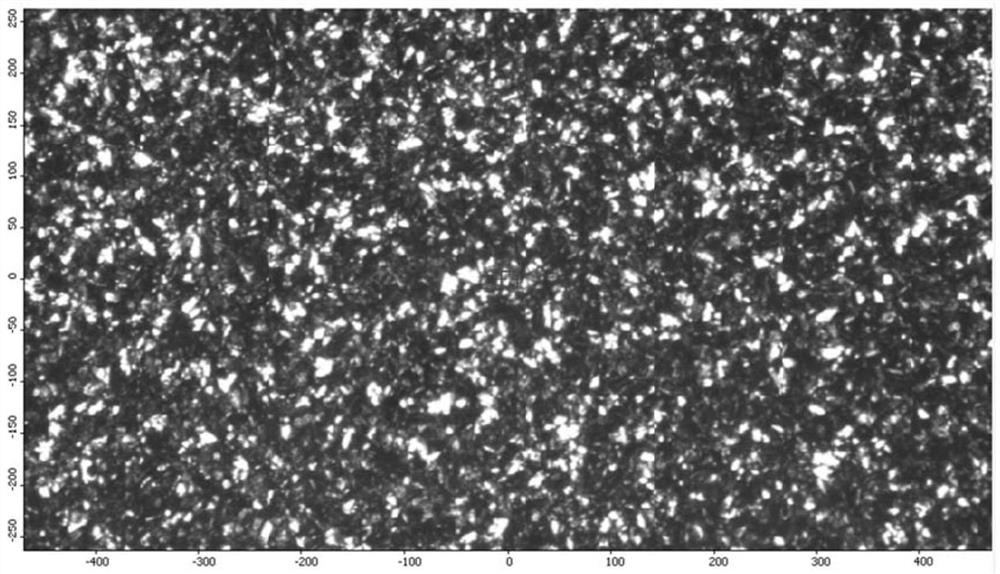

[0070] A kind of diamond composite material, comprises CVD diamond layer 1 and polycrystalline diamond composite layer 2, described polycrystalline diamond composite layer 2 comprises polycrystalline diamond layer 21 and cemented carbide layer 22, and described polycrystalline diamond layer 21 is provided with all Between the CVD diamond layer 1 and the hard alloy layer 22; from the side near the CVD diamond layer 1 to the side near the hard alloy layer 22, the metal content in the polycrystalline diamond layer 21 increases, wherein, near The metal content in the polycrystalline diamond layer 21 on one side of the CVD diamond layer 1 is 0wt%, the metal content in the polycrystalline diamond layer 21 on the side near the hard alloy layer 22 is 1wt%, and the metal content increasing rate is 0.2 wt% / mm. The optical microscope image of the CVD diamond layer in the diamond composite is shown in figure 2 , see the Raman spectrum image 3 .

[0071] The preparation method of this...

Embodiment 2

[0082] A kind of diamond composite material, comprises CVD diamond layer 1 and polycrystalline diamond composite layer 2, described polycrystalline diamond composite layer 2 comprises polycrystalline diamond layer 21 and cemented carbide layer 22, and described polycrystalline diamond layer 21 is provided with all Between the CVD diamond layer 1 and the hard alloy layer 22; from the side near the CVD diamond layer 1 to the side near the hard alloy layer 22, the metal content in the polycrystalline diamond layer 21 increases, wherein, near The metal content in the polycrystalline diamond layer 21 on one side of the CVD diamond layer 1 is 0.4wt%, and the metal content in the polycrystalline diamond layer 21 on the side near the hard alloy layer 22 is 6wt%, and the increasing rate of the metal content is 20 wt% / mm.

[0083] The preparation method of this diamond composite material comprises the steps:

[0084] 1) Polishing the polycrystalline diamond layer in the polycrystalline...

Embodiment 3

[0094] A kind of diamond composite material, comprises CVD diamond layer 1 and polycrystalline diamond composite layer 2, described polycrystalline diamond composite layer 2 comprises polycrystalline diamond layer 21 and cemented carbide layer 22, and described polycrystalline diamond layer 21 is provided with all Between the CVD diamond layer 1 and the hard alloy layer 22; from the side near the CVD diamond layer 1 to the side near the hard alloy layer 22, the metal content in the polycrystalline diamond layer 21 increases, wherein, near The metal content in the polycrystalline diamond layer 21 on one side of the CVD diamond layer 1 is 1wt%, the metal content in the polycrystalline diamond layer 21 on the side near the hard alloy layer 22 is 5wt%, and the metal content increasing rate is 2.5 wt% / mm.

[0095] The preparation method of this diamond composite material comprises the steps:

[0096] 1) Polishing the polycrystalline diamond layer in the polycrystalline diamond com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com