Method and device for preparing micro/nano structure material

A technology of nanostructures and target materials, applied in the field of preparation of micro/nanostructures, can solve problems such as uneven product size and shape, complex devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] use Image 6 device shown.

[0104] Deionized water is selected as the bulk liquid, and it is preheated, that is, the solution substrate is heated to 30°C.

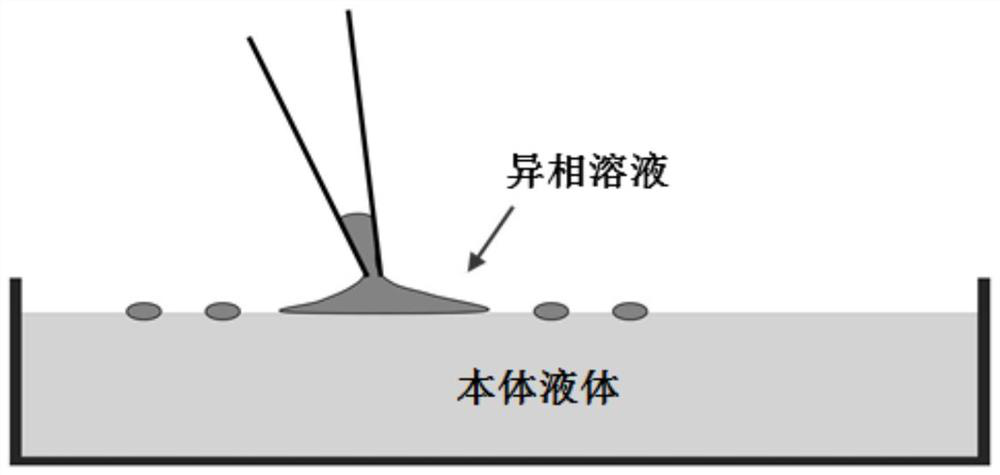

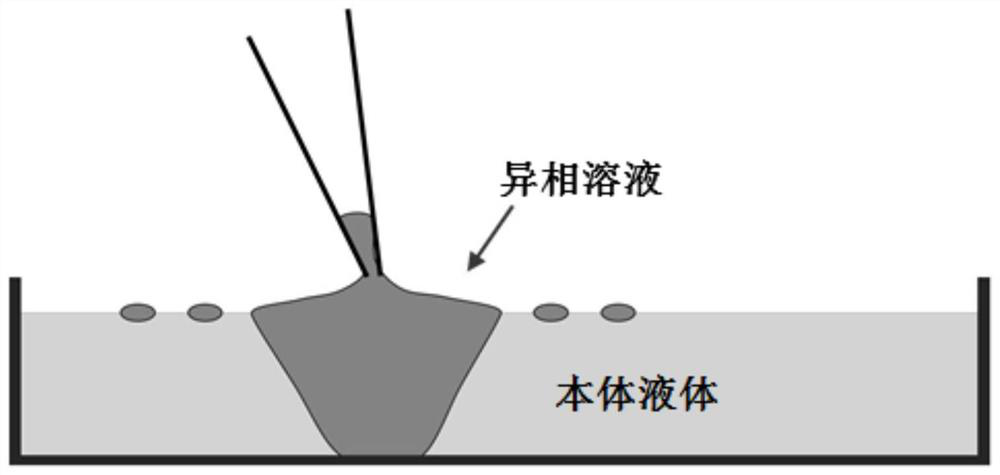

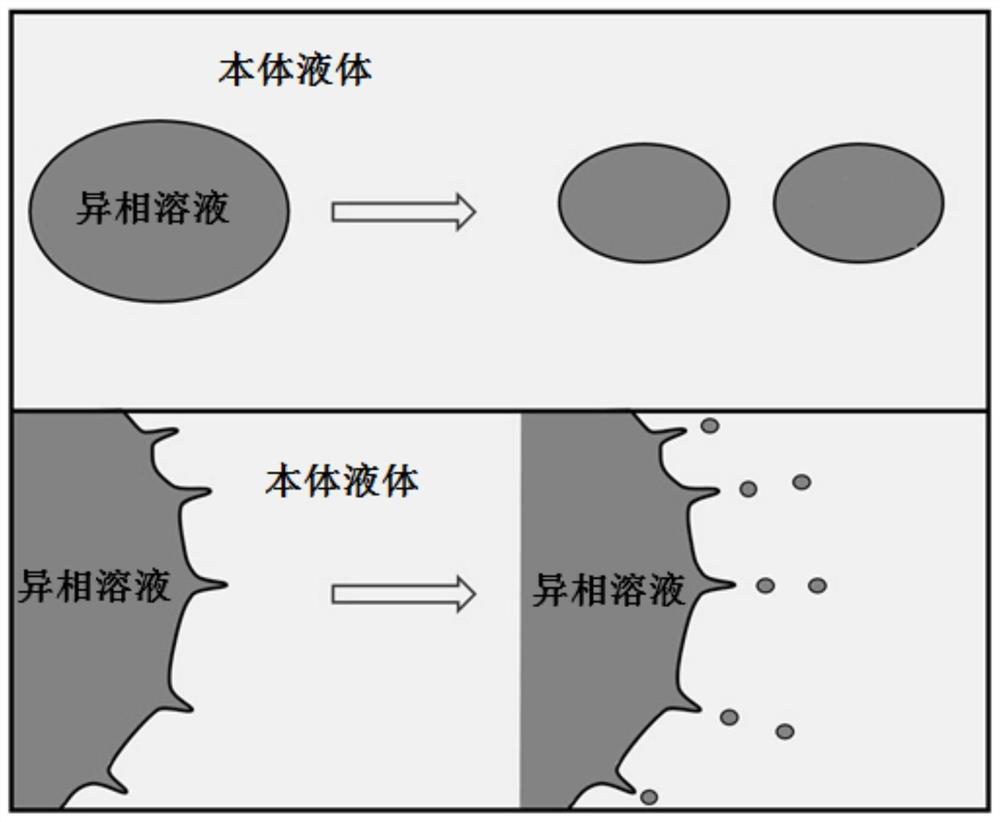

[0105] choose C 60 Chlorobenzene solution (its concentration is 1mg / mL), forms heterogeneous solution, and heterogeneous solution is added dropwise to bulk liquid interface, and solution has spreading tendency on substrate surface and carries out self-disintegration.

[0106] The liquid-liquid system is heated to 40-50°C, and 500 sccm of air is purged inward to change the ambient pressure of the system to obtain micro / nano-structured C 60 .

[0107] to get C 60 Perform atomic force microscopy, such as Figure 7 As shown in (a), crystalline particles having a dumbbell shape were obtained.

[0108] The same process applies to cooling the entire system.

Embodiment 2

[0110] Repeat the process of embodiment 1, difference is: what heterogeneous solution adopts is C 60 carbon tetrachloride solution, and without heat treatment of the liquid-liquid system, the micro / nano-structured C 60 .

[0111] to get C 60 Perform atomic force microscopy, such as Figure 7 As shown in (b), get C 60 Flaky single crystal structure.

Embodiment 3

[0113] Repeat the process of embodiment 1, difference is: what heterogeneous solution adopts is C 60 carbon tetrachloride solution, at a system temperature of 20°C, micro / nano-structured C 60 .

[0114] to get C 60 Perform atomic force microscopy, such as Figure 7 As shown in (c), get C 60 ring structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com