In-situ soil remediation system and remediation method based on gas thermal desorption

A technology of soil remediation and thermal desorption, which is applied in the in-situ soil remediation system based on gas thermal desorption and the field of remediation, which can solve the problems of high energy consumption, inability to achieve thermal desorption of organic matter, long repair period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

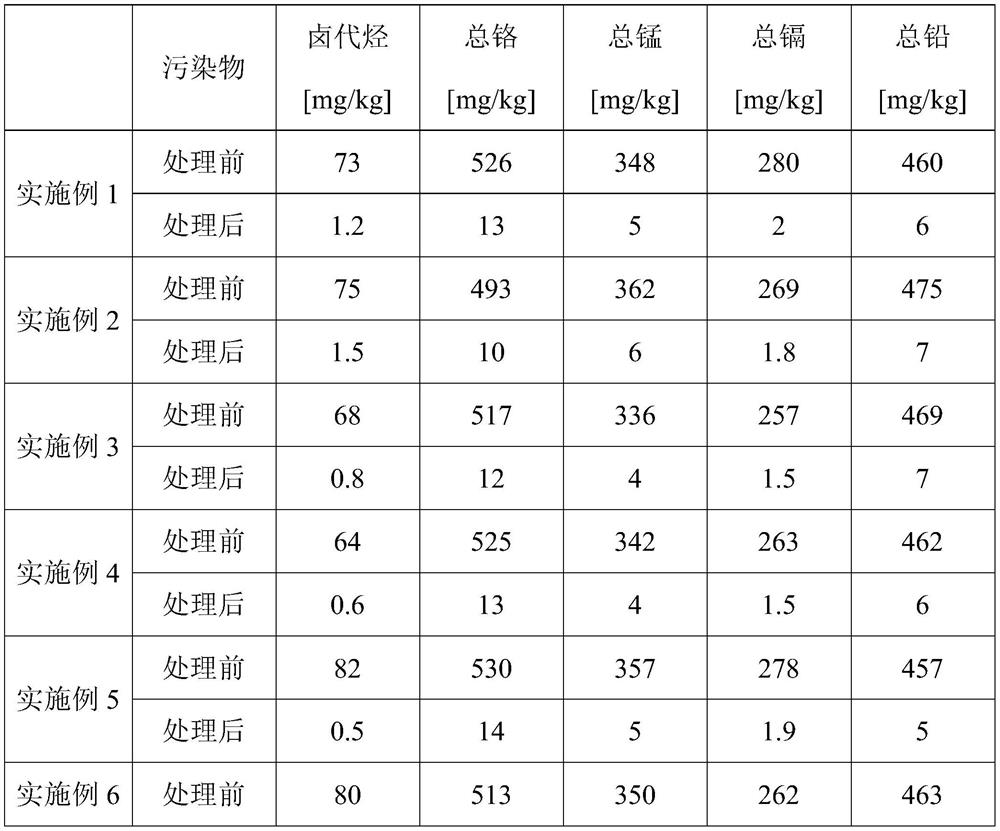

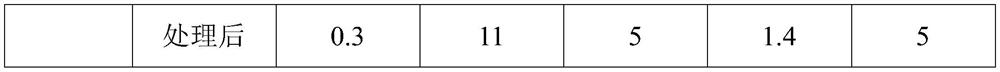

Embodiment 1

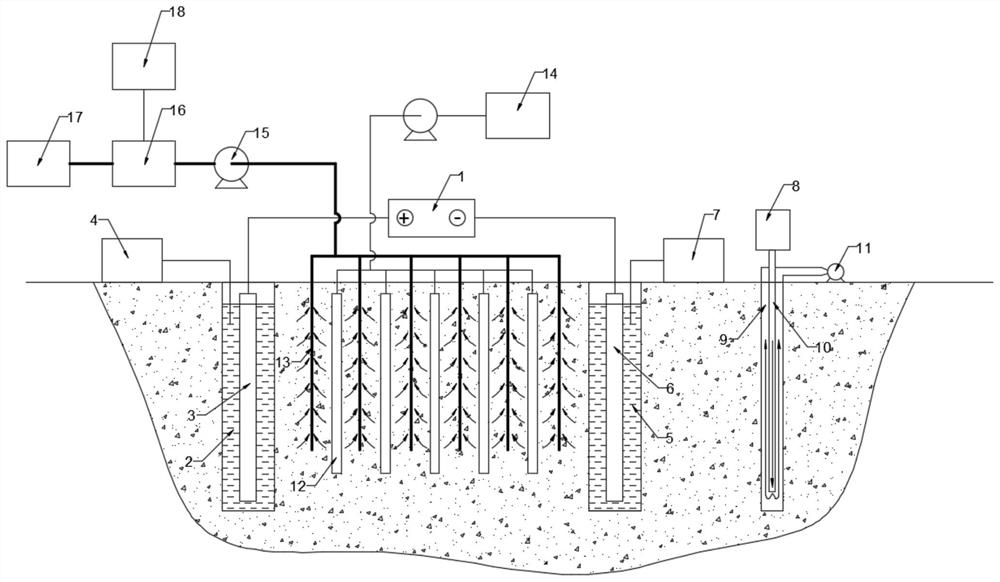

[0073] This embodiment provides a method for in-situ remediation of polluted soil, the processed polluted soil heavy metals include the highest content of total chromium, total manganese, total cadmium and total lead respectively 526mg / kg, 348mg / kg and 280mg / kg kg and 460mg / kg, the highest content of volatile organic compound halogenated hydrocarbons is 73mg / kg, and the contaminated soil area containing the above-mentioned pollutants is repaired in situ, and the soil restoration method described includes the following steps:

[0074] (1) Fully infiltrate the polluted soil, pass gas and air into the combustion device 8 through the gas pipe and the air pipe respectively, the volume ratio of gas and air feeding is 1:4, after the gas is mixed with air in the combustion device 8 The hot air generated by ignition passes through the inner pipe 10 from top to bottom, deflects from the bottom of the inner pipe 10 and enters the outer pipe 9, flows through the outer pipe 9 from top to bo...

Embodiment 2

[0080] This embodiment provides a method for in-situ remediation of polluted soil, the processed polluted soil heavy metals include the highest content of total chromium, total manganese, total cadmium and total lead respectively 493mg / kg, 362mg / kg and 269mg / kg kg and 475mg / kg, the highest content of volatile organic compound halogenated hydrocarbons is 75mg / kg, and the contaminated soil area containing the above pollutants is repaired in situ, and the soil restoration method includes the following steps:

[0081] (1) Fully infiltrate the polluted soil, pass gas and air to the combustion device 8 through the gas pipe and the air pipe respectively, the volume ratio of gas and air feeding is 1:4.2, after the gas is mixed with air in the combustion device 8 The hot air generated by ignition passes through the inner pipe 10 from top to bottom, deflects from the bottom of the inner pipe 10 and enters the outer pipe 9, flows through the outer pipe 9 from top to bottom, and is dischar...

Embodiment 3

[0087] This embodiment provides a method for in-situ remediation of polluted soil, the processed polluted soil heavy metals include the highest content of total chromium, total manganese, total cadmium and total lead respectively 517mg / kg, 336mg / kg and 257mg / kg kg and 469mg / kg, the highest content of volatile organic compound halogenated hydrocarbons is 68mg / kg, and the contaminated soil area containing the above-mentioned pollutants is repaired in situ, and the soil restoration method described includes the following steps:

[0088] (1) Fully infiltrate the polluted soil, pass gas and air into the combustion device 8 through the gas pipe and the air pipe respectively, the volume ratio of gas and air feeding is 1:4.4, after the gas is mixed with air in the combustion device 8 The hot air generated by ignition passes through the inner pipe 10 from top to bottom, deflects from the bottom of the inner pipe 10 and enters the outer pipe 9, flows through the outer pipe 9 from top to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com