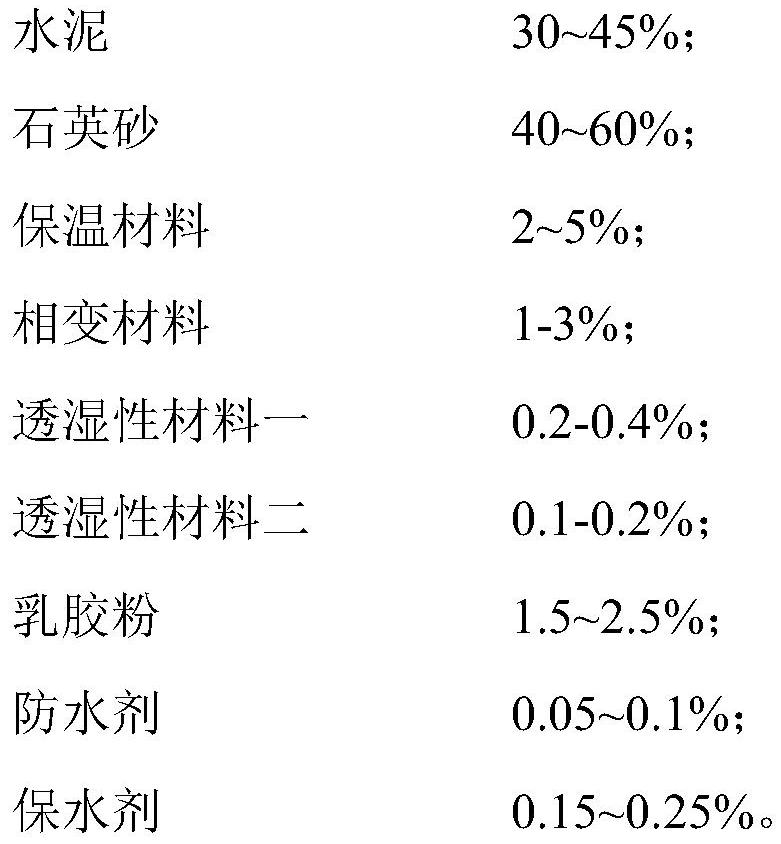

Heat-preservation moisture-permeable rendering coat mortar for building and preparation method thereof

A technology for building thermal insulation and plastering glue, which is applied in climate sustainability, sustainable waste treatment, solid waste management, etc. Small difference, high wet flow density, and the effect of reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

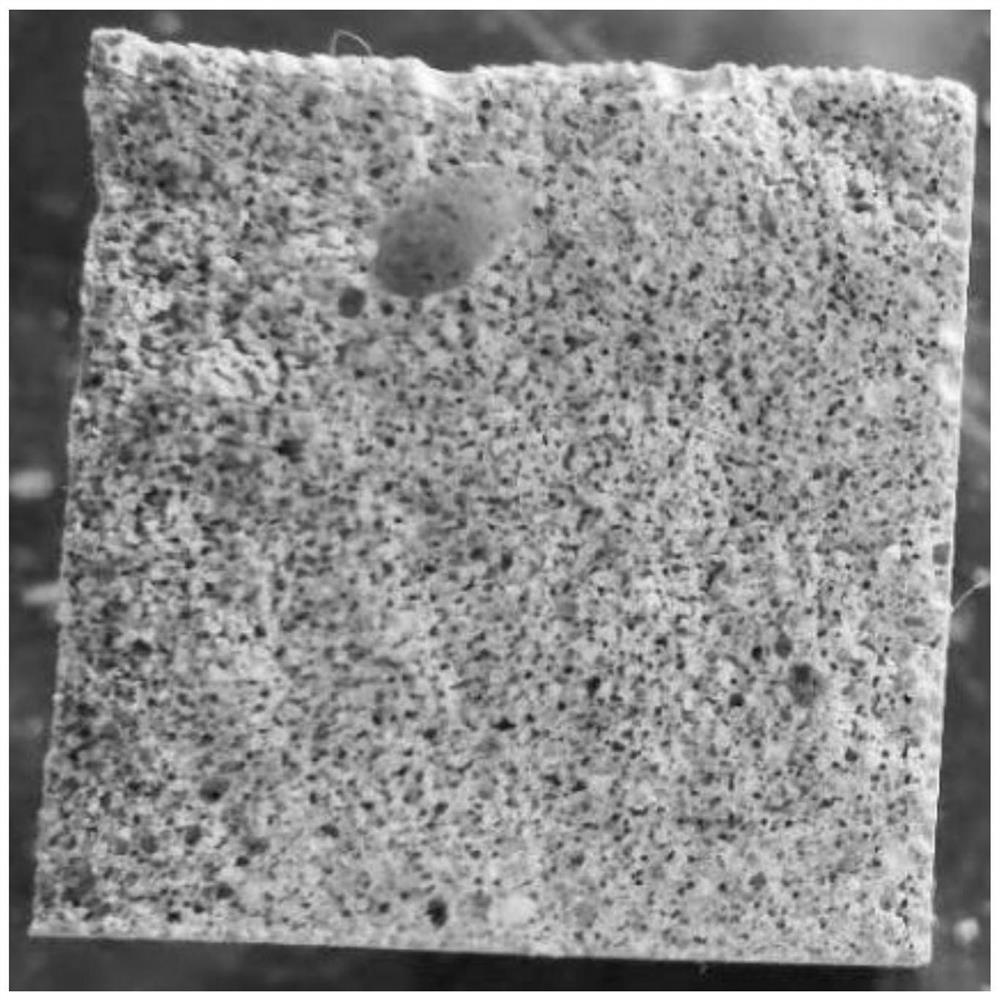

Image

Examples

Embodiment 1

[0040] A building thermal insulation and moisture-permeable plaster mortar, the preparation method of which comprises the following steps:

[0041](1) 40 parts (parts by weight, the same below) P.O42.5# ordinary Portland cement, 51.43 parts of quartz sand, 3.5 parts of polystyrene foam particles, 0.25 parts of wood fiber, 0.11 part of polyvinyl alcohol fiber , 2.2 parts of ethylene-vinyl acetate latex powder, 0.08 part of octyltriethoxysilane powder, and 0.23 part of hydroxymethylpropyl cellulose are added to the stirring equipment together, and stirred at a slow speed (50~60r / min) for 1.8h ;

[0042] (2) Add 2.2 parts of paraffin wax powder into the above-mentioned reactants, continue stirring at a slow speed for 0.5 h, and obtain the building thermal insulation and moisture-permeable plastering mortar of the present invention.

Embodiment 2

[0044] A building thermal insulation and moisture-permeable plaster mortar, the preparation method of which comprises the following steps:

[0045] (1) 35.52 parts of P.O42.5# ordinary Portland cement, 56 parts of quartz sand, 1.6 parts of polystyrene foam particles, 2.1 parts of hollow glass beads, 0.31 parts of wood fiber, 0.14 parts of polyvinyl alcohol fiber, Add 1.5 parts of ethylene-vinyl acetate latex powder, 0.1 part of octyltriethoxysilane powder, and 0.23 parts of hydroxyethyl cellulose into the stirring equipment, and stir at a slow speed (50~60r / min) for 2 hours;

[0046] (2) Add 2.5 parts of paraffin wax powder into the above-mentioned reactant, continue stirring at a slow speed for 0.5 h, and obtain the building thermal insulation and moisture-permeable plastering mortar of the present invention.

Embodiment 3

[0048] A building thermal insulation and moisture-permeable plaster mortar, the preparation method of which comprises the following steps:

[0049] (1) 31.63 parts of P.O52.5# ordinary Portland cement, 58 parts of quartz sand, 2.2 parts of expanded perlite, 2.8 parts of hollow glass microspheres, 0.35 parts of wood fiber, 0.1 part of polyvinyl alcohol fiber, 1.8 parts Add ethylene-vinyl acetate latex powder, 0.12 parts of octyltriethoxysilane powder, and 0.2 parts of hydroxyethyl cellulose into the stirring equipment, and stir at a slow speed (50-60 r / min) for 2 hours;

[0050] (2) Add 2.8 parts of paraffin wax powder into the above-mentioned reactant, continue stirring at a slow speed for 0.5 h, and obtain the building thermal insulation and moisture-permeable plastering mortar of the present invention.

[0051] The plaster mortar that embodiment 1-3 makes is carried out performance test:

[0052] The general physical properties are tested according to the standard GB / T 3059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com