Method for synthesizing ethyl N-methyl cyanocarbamate by methylation reagent

A technology of ethyl cyanocarbamate and ethyl cyanocarbamate, which is applied in the field of methylating reagents to synthesize ethyl N-methylcyanocarbamate, and can solve problems such as potential safety hazards and corrosion of wastewater treatment facilities and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

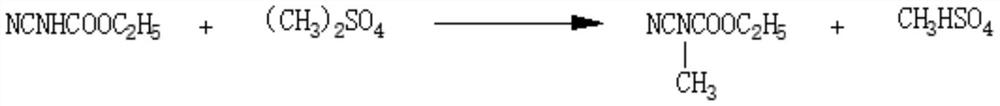

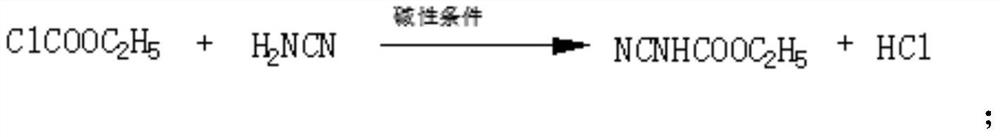

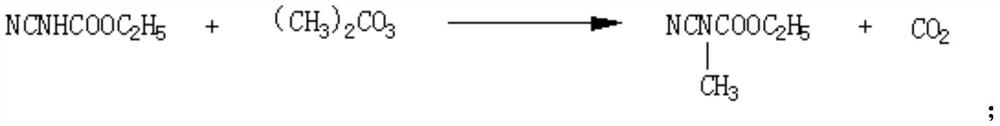

Method used

Image

Examples

Embodiment 1

[0031] Add 140g (1mol) of 30% cyanamide solution and 114g (1.05mol) of ethyl chloroformate into a 1000mL reaction flask equipped with a mechanical stirring device and a thermometer, start stirring, control the temperature in the reaction flask at 10-30°C, drop Add 30% sodium hydroxide solution until the pH value is 6.0, raise the temperature to 30-50°C and keep it warm for 3h. Then the temperature was lowered to 20-30° C., 99 g (1.1 mol) of dimethyl carbonate was added dropwise, and after the dropwise addition, the temperature was raised to 30-50° C. and kept for 3 hours. After the heat preservation was completed, it was cooled to room temperature, and transferred to a separatory funnel for static layering. The waste water in the lower layer was separated to obtain ethyl N-methylcyanocarbamate with a content of 97% and a yield of 95%.

Embodiment 2

[0033] Add 140g (1mol) of 30% cyanamide solution and 108.5g (1mol) of ethyl chloroformate into a 1000mL reaction flask equipped with a mechanical stirring device and a thermometer, start stirring, control the temperature in the reaction flask at 10-30°C, drop Add 30% sodium hydroxide solution until the pH value is 7.0, raise the temperature to 30-50°C and keep it warm for 3h. Then the temperature was lowered to 20-30° C., 90 g (1 mol) of dimethyl carbonate was added dropwise, and after the dropwise addition, the temperature was raised to 30-50° C. and kept for 3 hours. After the heat preservation was completed, it was cooled to room temperature, and transferred to a separatory funnel for static layering. The waste water in the lower layer was separated to obtain ethyl N-methylcyanocarbamate with a content of 95% and a yield of 93%.

Embodiment 3

[0035] Add 140g (1mol) of 30% cyanamide solution and 110.7g (1.02mol) of ethyl chloroformate into a 1000mL reaction flask equipped with a mechanical stirring device and a thermometer, start stirring, and control the temperature in the reaction flask at 10-30°C. 50% sodium hydroxide solution was added dropwise until the pH value was 7.0, and the temperature was raised to 30-50° C. for 3 hours. Then the temperature was lowered to 20-30° C., 94.5 g (1.05 mol) of dimethyl carbonate was added dropwise, and after the dropwise addition, the temperature was raised to 30-50° C. and kept for 3 hours. After the heat preservation was completed, it was cooled to room temperature, and transferred to a separatory funnel for static layering. The waste water in the lower layer was separated to obtain ethyl N-methylcyanocarbamate with a content of 96% and a yield of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com