High-elongation imidazolium salt doped conductive elastomer and preparation method thereof

A technique of molarizing imidazoles and elastomers, which is applied in the field of conductive elastomers. It can solve the problems of material conductivity decline, conductive fillers are easy to agglomerate, and the preparation process is complicated. It achieves the effects of good conductivity, large optimization space, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

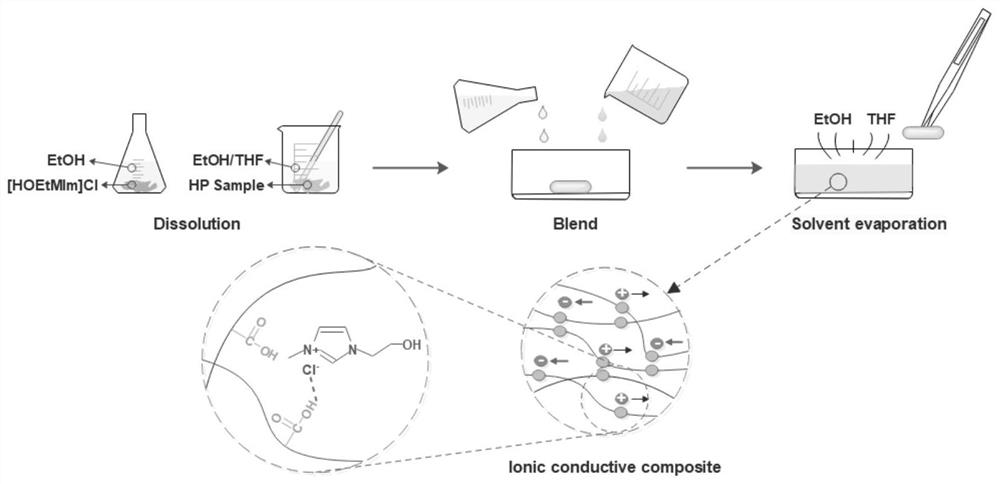

[0029] Embodiment 1: the preparation of the conductive elastomer of imidazolium salt doping

[0030] Add 0.60 g of [HOEtMIm]Cl and 4.0 g of carboxyl-containing polyacrylate elastomer to 15 mL of ethanol and 5 mL of tetrahydrofuran mixed solvent, obtain a homogeneous solution after stirring and transfer the solution to a 60 mm inner diameter tetrafluoroethylene petri dish Set aside to evaporate the solvent. Subsequently, the initially obtained composite film doped with imidazolium salt was further dried in a blast oven at 90°C for 3 hours to obtain a conductive elastomer film material, which was stored in a desiccator equipped with silica gel for future use.

Embodiment 2

[0031] Embodiment 2: Preparation of the conductive elastomer doped with imidazolium salt

[0032] Add 1.0 g of [HOEtMIm]Cl and 4.0 g of carboxyl-containing polyacrylate elastomer to 15 mL of ethanol and 5 mL of tetrahydrofuran mixed solvent, obtain a homogeneous solution after stirring, and transfer the solution to a 60 mm tetrafluoroethylene Petri dish. Set aside to evaporate the solvent. Subsequently, the initially obtained composite film doped with imidazolium salt was further dried in a blast oven at 90°C for 3 hours to obtain a conductive elastomer film material, which was stored in a desiccator equipped with silica gel for future use.

Embodiment 3

[0033] Embodiment 3: the preparation of the conductive elastomer of imidazolium salt doping

[0034] Add 1.4 g of [HOEtMIm]Cl and 4.0 g of carboxyl-containing polyacrylate elastomer to 15 mL of ethanol and 5 mL of tetrahydrofuran mixed solvent, obtain a homogeneous solution after stirring, and transfer the solution to a 60 mm tetrafluoroethylene Petri dish. Set aside to evaporate the solvent. Subsequently, the initially obtained composite film doped with imidazolium salt was further dried in a blast oven at 90°C for 3 hours to obtain a conductive elastomer film material, which was stored in a desiccator equipped with silica gel for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com