Self-expanding lignofoam compositions and lignofoams made therefrom

A self-expanding, composite technology applied in the field of lignin foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

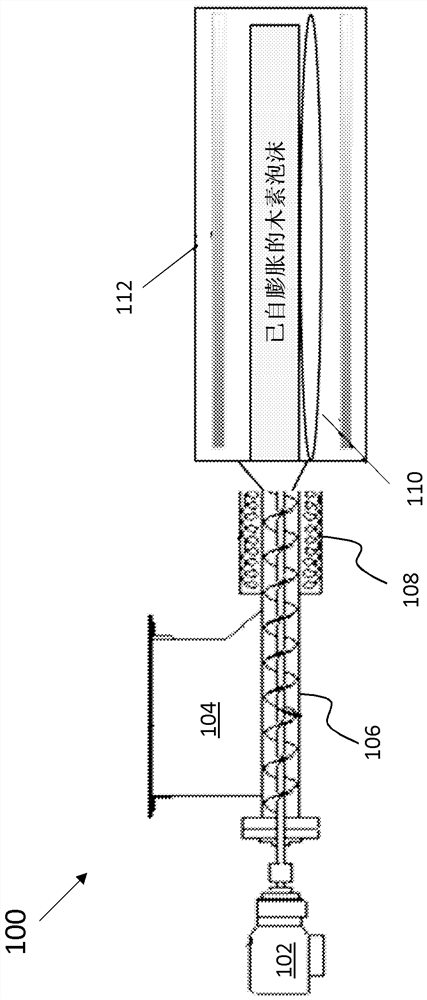

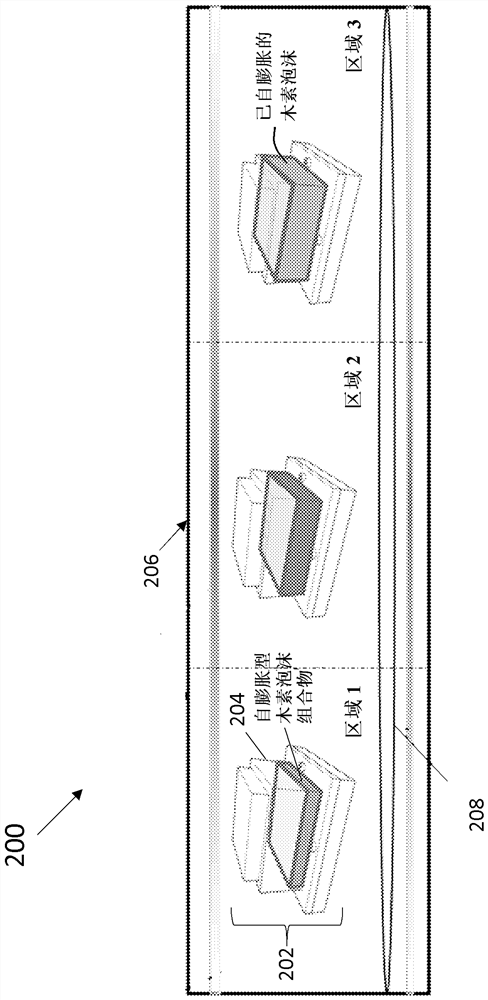

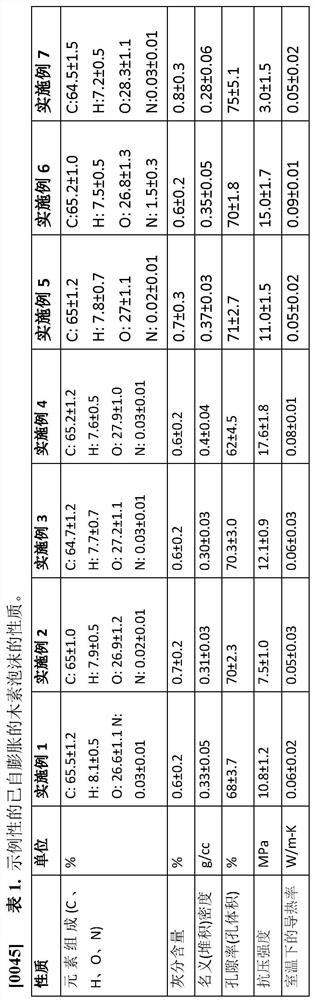

Embodiment 1

[0033] In this example, 240 grams of kraft lignin (raw lignin) and 60 grams of poly(ethylene) powder were placed in a blender and mixed very well for 30 minutes. Then transfer the composition to figure 2 The molding chamber of the molding system. Experiments were performed as follows. The composition is cold pressed at a pressure between 0 (no pressure) and 10 MPa. The (pressed) composition is transferred in the forming chamber to the heating chamber and a metal plate is placed on the pressed composition, the metal plate exerting a pressure of 10-10,000 Pa. The heating chamber is then heated to a temperature of 200-260° C. at a rate of 5-20° C. / minute and held for 30-60 minutes. Next, the molding chamber is cooled to room temperature. These experiments produced open-celled, self-expanding lignin foams, which were subsequently removed from the mould. Results from a representative sample of lignin foam that had self-expanded are shown in Table 1 below.

Embodiment 2

[0035] In this example, 270 grams of kraft lignin (raw lignin) and 30 grams of polypropylene were placed in a mixer and mixed very thoroughly for 30 minutes. Then transfer the composition to figure 2 The molding chamber of the molding system. Experiments were performed as follows. The composition is cold pressed at a pressure between 0 (no pressure) and 10 MPa. The (pressed) composition is transferred in the forming chamber to the heating chamber and a metal plate is placed on the pressed composition, the metal plate exerting a pressure of 10-10,000 Pa. The heating chamber is then heated to a temperature of 220-260° C. at a rate of 5-20° C. / minute and held for 30-60 minutes. Next, the molding chamber is cooled to room temperature. These experiments produced open-celled, self-expanding lignin foams, which were subsequently removed from the mould. Results from a representative sample of lignin foam that had self-expanded are shown in Table 1 below.

Embodiment 3

[0037] In this example, 250 grams of kraft lignin (raw lignin) and 50 grams of poly(methyl methacrylate) were placed in a mixer and mixed very thoroughly for 30 minutes. Then transfer the composition to figure 2 The molding chamber of the molding system. Experiments were performed as follows. The composition is cold pressed at a pressure between 0 (no pressure) and 10 MPa. The (pressed) composition is transferred in the forming chamber to the heating chamber and a metal plate is placed on the pressed composition, the metal plate exerting a pressure of 10-10,000 Pa. The heating chamber is then heated to a temperature of 200-250° C. at a rate of 5-20° C. / minute and held for 30-60 minutes. Next, the molding chamber is cooled to room temperature. These experiments produced open-celled, self-expanding lignin foams, which were subsequently removed from the mould. Results from a representative sample of lignin foam that had self-expanded are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com