Cold heading steel hot rolled wire rod for large-size wind power bolts and preparation method thereof

A technology for wind power bolts and hot-rolled wire rods, which is applied in the field of cold heading steel and hot-rolled wire rods, can solve the problems of reducing low temperature notch sensitivity, unfavorable high temperature tempering brittleness, and heat treatment performance that does not meet the performance of 10.9-level wind power bolts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

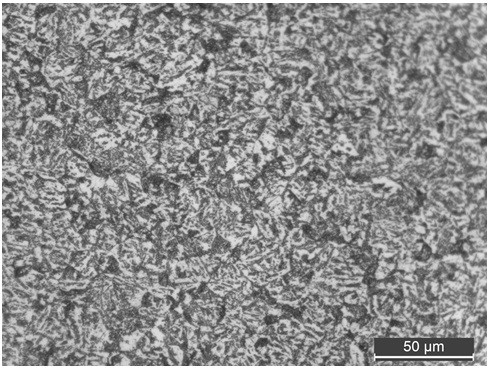

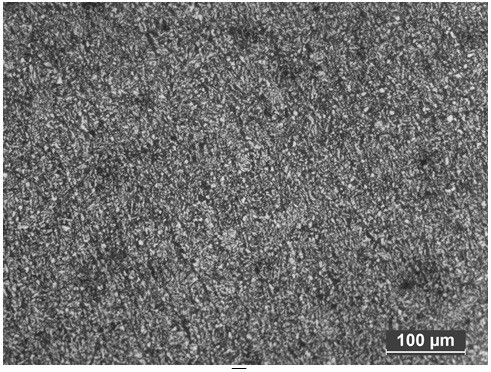

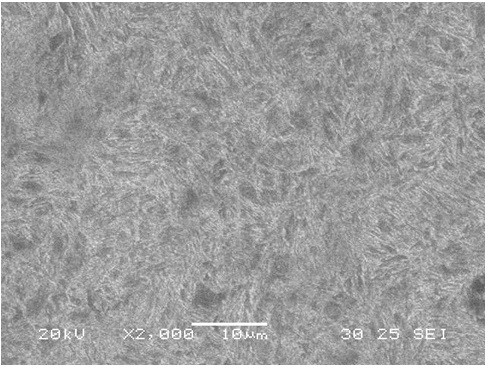

Embodiment 1

[0041] Example 1 The chemical composition and weight percentage of the wire rod are listed in Table 1. The wire rod preparation process is: bloom heating → billet opening → slow cooling → hot rolling billet heating → controlled rolling → controlled cooling → finished product Wire rod, bloom heating process, the steel billet is heated to 1230 ℃, the holding time is 380min, and the residual oxygen content of the heating furnace is 1.2%. In the hot-rolled slab heating process, the slab is heated to 1100°C, the holding time is 101min, and the residual oxygen in the heating furnace is 4.0%. The rolling process is controlled, the finishing rolling temperature is 910°C, and the spinning temperature is 779°C. Control the cooling process. After spinning, the wire rod is cooled by air blowing at 1.0°C / s to 558°C, and then enters the running channel covered with a heat preservation cover for slow cooling, and the slow cooling time is 40 minutes. The specification of hot-rolled wire rod ...

Embodiment 2

[0043] Example 2 The chemical composition and weight percentage of the wire rod are listed in Table 1. The wire rod preparation process is: bloom heating → billet opening → slow cooling → hot rolling billet heating → controlled rolling → controlled cooling → finished product Wire rod, bloom heating process, the steel billet is heated to 1249 ℃, the holding time is 340min, and the residual oxygen content of the heating furnace is 2.1%. In the hot-rolled slab heating process, the slab is heated to 1121°C, the holding time is 106 minutes, and the residual oxygen in the heating furnace is 2.1%. The rolling process is controlled, the finishing rolling temperature is 921°C, and the spinning temperature is 750°C. Control the cooling process. After spinning, the wire rod is cooled by air blowing, and cooled to 550°C at 1.4°C / s, and then enters the running channel covered with a heat preservation cover for slow cooling, and the slow cooling time is 33 minutes. The specification of hot...

Embodiment 3

[0045] Example 3 The chemical composition and weight percentage of the wire rod are listed in Table 1. The wire rod preparation process is: bloom heating → billet opening → slow cooling → hot rolling billet heating → controlled rolling → controlled cooling → finished product Wire rod, bloom heating process, the steel billet is heated to 1260 ℃, the holding time is 361min, and the residual oxygen content of the heating furnace is 2.5%. In the hot-rolled slab heating process, the slab is heated to 1128°C, the holding time is 96 minutes, and the residual oxygen content of the heating furnace is 3.1%. The rolling process is controlled, the finishing rolling temperature is 931°C, and the spinning temperature is 769°C. Control the cooling process. After spinning, the wire rod is cooled by air blowing, and cooled to 566°C at 1.8°C / s, and then enters the running channel covered with a heat preservation cover for slow cooling, and the slow cooling time is 25 minutes. The specification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com