Manufacturing method of non-woven fabric material for paper diapers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

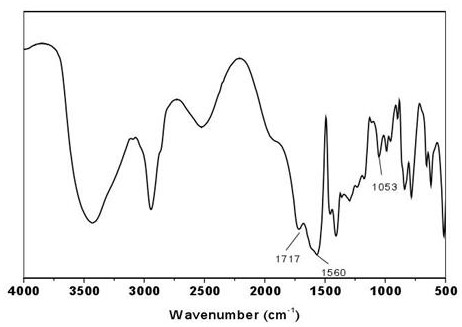

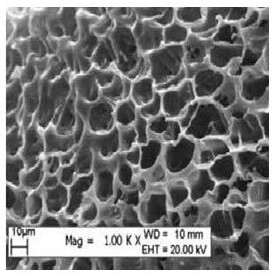

Image

Examples

preparation example Construction

[0031] A preparation method of a non-woven fabric material for paper diapers, comprising the following steps:

[0032] (1) Add methyl cellulose to the reaction kettle, then add deionized water, heat to 50-55°C, keep stirring for 30 minutes, then add maleic anhydride and graphene, continue stirring for 10-15 minutes, then add Catalyst, stirred and reacted for 2 hours, then washed with acetone and clear water successively, and dried to obtain the intermediate;

[0033] Methylcellulose:

[0034] Appearance off-white fibrous to rice powder;

[0035] Gel temperature (2% aqueous solution) 50~55℃;

[0036] Methoxyl content 26%~33%;

[0037] Water insoluble matter ≤2.0%;

[0038] Degree of substitution (DS) 1.3~2.0;

[0039] Moisture ≤5.0%;

[0040] Viscosity (20℃, 2% aqueous solution) 15~4000mPa·s;

[0041] maleic anhydride:

[0042] Chemical formula C 4 h 2 o 3

[0043] Molar mass 98.06 g / mol;

[0044] Appearance White crystals with a sour taste;

[0045] Density 1.48 ...

Embodiment 1

[0069] A preparation method of a non-woven fabric material for paper diapers, comprising the following steps:

[0070] (1) Add methyl cellulose to the reaction kettle, then add deionized water, heat to 50°C, keep stirring for 30 minutes, then add maleic anhydride and graphene, continue stirring for 10 minutes, then add catalyst, and stir the reaction 2 hours, then washed with acetone and water in sequence, and dried to obtain an intermediate, the mixing mass ratio of methyl cellulose and deionized water was 1:5. The mass ratio of maleic anhydride to graphene and methyl cellulose is 1:0.3:35. Described catalyzer is pyridine; Described catalyzer addition and maleic anhydride mass ratio are 1:4;

[0071] (2) Add polypropylene resin, stearate, and nanofillers to a high-speed mixer for mixing, and then add them to an extruder for extrusion granulation to obtain a preliminary masterbatch; the polypropylene resin, stearin The mass ratio of acid salt and nano filler is 85:5:6. The ...

Embodiment 2

[0075] A preparation method of a non-woven fabric material for paper diapers, comprising the following steps:

[0076] (1) Add methyl cellulose to the reaction kettle, then add deionized water, heat to 55°C, keep stirring for 30 minutes, then add maleic anhydride and graphene, continue stirring for 15 minutes, then add catalyst, and stir for reaction 2 hours, and then successively wash with acetone and clear water, and dry to obtain an intermediate, the mixing mass ratio of methyl cellulose and deionized water is 1:6. The mass ratio of maleic anhydride to graphene and methyl cellulose is 2:0.5:40. Described catalyzer is pyridine; Described catalyzer addition and maleic anhydride mass ratio are 1:5;

[0077] (2) Add polypropylene resin, stearate, and nanofillers to a high-speed mixer for mixing, and then add them to an extruder for extrusion granulation to obtain a preliminary masterbatch; the polypropylene resin, stearin The mass ratio of salt and nano filler is 90:7:8. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com