Ultrathin soaking plate with high strength and light weight

A vapor chamber, lightweight technology, used in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., which can solve the problem of weakening material strength, warping and bending of vapor chambers, and affecting the thermal performance of products. and mechanical properties, to ensure the anti-deformation ability, improve the stability and firmness, and achieve the effect of good thickness uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

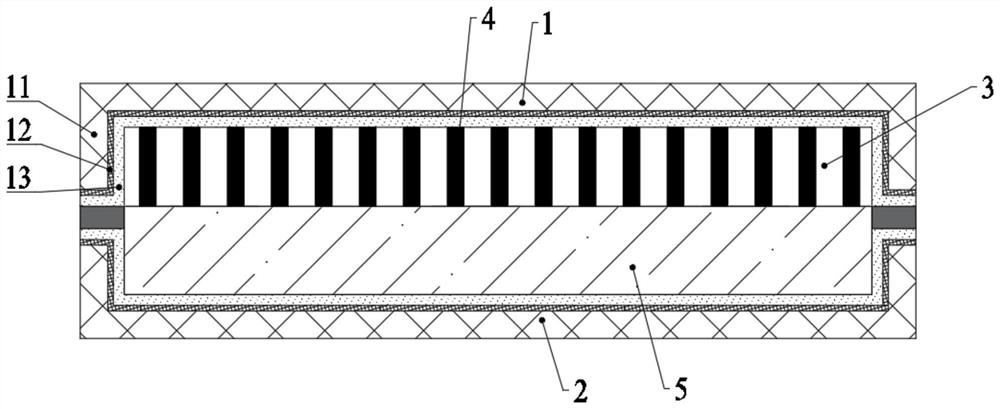

[0017] Such as figure 1 As shown, a high-strength and lightweight ultra-thin vapor chamber includes an upper cover plate 1 and a lower cover plate 2 that are sealed and connected around the periphery to form a sealed working medium cavity 3. The sealed working medium cavity 3 is in a vacuum state and filled with liquid The working medium, the upper cover 1 and the lower cover 2 are made of composite materials to form a high-strength and light-weight cavity wall. The lower surface of the upper cover 1 and the upper surface of the lower cover 2 are concave, and the upper cover A plurality of support columns 4 are arranged in an array on the concave surface of 1, and a liquid-absorbing core 5 is arranged on the concave surface of the lower cover plate 2.

[0018] The thickness of the upper cover plate 1 is 0.15 mm, and a support column with a height of 0.1 mm is etched inside. The wall surface material is a composite material, including a first material layer 11, a second materi...

Embodiment 2

[0026] A high-strength and light-weight ultra-thin vapor chamber, including an upper cover plate 1 and a lower cover plate 2 that are sealed and connected around the periphery to form a sealed working medium cavity 3, the sealed working medium cavity 3 is in a vacuum state, and is filled with a liquid working medium. Both the upper cover 1 and the lower cover 2 are made of composite materials to form a high-strength and light-weight cavity wall. The lower surface of the upper cover 1 and the upper surface of the lower cover 2 are both concave surfaces, and the arrays in the concave surface are arranged more A supporting column 4, the concave surface of the lower cover plate 2 is provided with a liquid-absorbing core 5.

[0027] The thickness of the upper cover plate 1 is 0.22mm, and the inner side is etched with a support column with a height of 0.18mm. Layer 13, wherein the first material layer 11 is high-strength light-weight stainless steel with a thickness of 60 microns; t...

Embodiment 3

[0035] A high-strength and light-weight ultra-thin vapor chamber, including an upper cover plate 1 and a lower cover plate 2 that are sealed and connected around the periphery to form a sealed working medium cavity 3, the sealed working medium cavity 3 is in a vacuum state, and is filled with a liquid working medium. The upper cover 1 and the lower cover 2 are both made of high-strength and lightweight composite materials, forming a high-strength and light-weight cavity wall. The lower surface of the upper cover 1 and the upper surface of the lower cover 2 are concave, and the concave A plurality of supporting columns 4 are arranged in an inner array, and a liquid-absorbing core 5 is provided on the concave surface of the lower cover plate 2 .

[0036] The thickness of the upper cover plate 1 is 0.35 mm, and the inner side is etched with a support column with a height of 0.23 mm. Layer 13, wherein the first material layer 11 is high-strength and lightweight stainless steel wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com