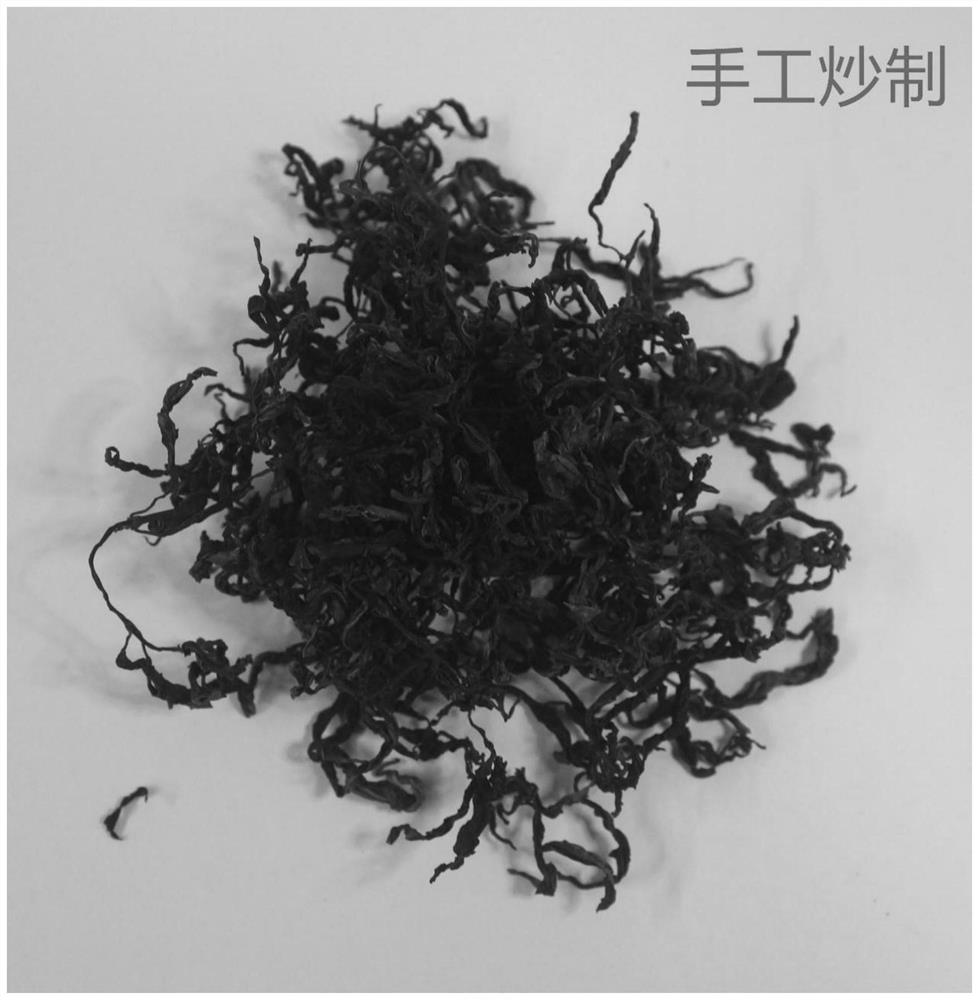

Method for mechanically frying clerodendranthus spicatus

A kidney tea and stir-frying technology, applied in the field of mechanically-frying kidney tea, can solve the problems of low efficiency of manual production, difficulty in adapting to large-scale production, and low product stability, and achieves fast production speed and improved stability. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for frying kidney tea by applying machinery, comprising the following steps:

[0035] (1) Picking: Pick clean leaves that are free from moth-eaten and non-withered yellow, and place them in a ventilated container to spread out to dry. Picking is to pick the clean leaves together with the petiole, pick the buds and the first leaf together, and pick the leaves below. The stems are not included, and the old leaves within 10cm from the ground are not picked, and the picking is carried out on non-rainy days;

[0036] (2) Softening: Scatter the kidney tea leaves in a sealed container and blow hot air inward from the bottom of the container. Blow the kidney tea leaves and heat them until they soften to a moisture content of 70%. Several air inlets are set at the bottom of the sealed container , several air outlets are set on the top, the time for blowing hot air is 20 minutes, and the temperature of blowing hot air is 50°C;

[0037] (3) Finishing: put the softened ki...

Embodiment 2

[0046] A method for frying kidney tea by applying machinery, comprising the following steps:

[0047](1) Picking: Pick clean leaves that are free from moth-eaten and non-withered yellow, and place them in a ventilated container to spread out to dry. Picking is to pick the clean leaves together with the petiole, pick the buds and the first leaf together, and pick the leaves below. The stems are not included, and the old leaves within 10cm from the ground are not picked, and the picking is carried out on non-rainy days;

[0048] (2) Softening: Scatter the kidney tea leaves in a sealed container and blow hot air inward from the bottom of the container. Blow the kidney tea leaves and heat them until they soften to a moisture content of 80%. Several air inlets are set at the bottom of the sealed container , several air outlets are set on the top, the time for blowing hot air is 40min, and the temperature of blowing hot air is 50°C;

[0049] (3) Finishing: put the softened kidney t...

Embodiment 3

[0058] A method for frying kidney tea by applying machinery, comprising the following steps:

[0059] (1) Picking: Pick clean leaves that are free from moth-eaten and non-withered yellow, and place them in a ventilated container to spread out to dry. Picking is to pick the clean leaves together with the petiole, pick the buds and the first leaf together, and pick the leaves below. The stems are not included, and the old leaves within 10cm from the ground are not picked, and the picking is carried out on non-rainy days;

[0060] (2) Softening: Scatter the kidney tea leaves in a sealed container and blow hot air inward from the bottom of the container. Blow the kidney tea leaves and heat them until they soften to a moisture content of 75%. Several air inlets are set at the bottom of the sealed container , several air outlets are set on the top, the time for blowing hot air is 30 minutes, and the temperature of blowing hot air is 60°C;

[0061] (3) Finishing: put the softened ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com