Biogas engineering biogas slurry solid-liquid separation system and control mode

A solid-liquid separation and biogas slurry technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the difficulties in meeting the requirements of multiple biogas slurry treatment methods, failure of solid-liquid separation system operation, complex control methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

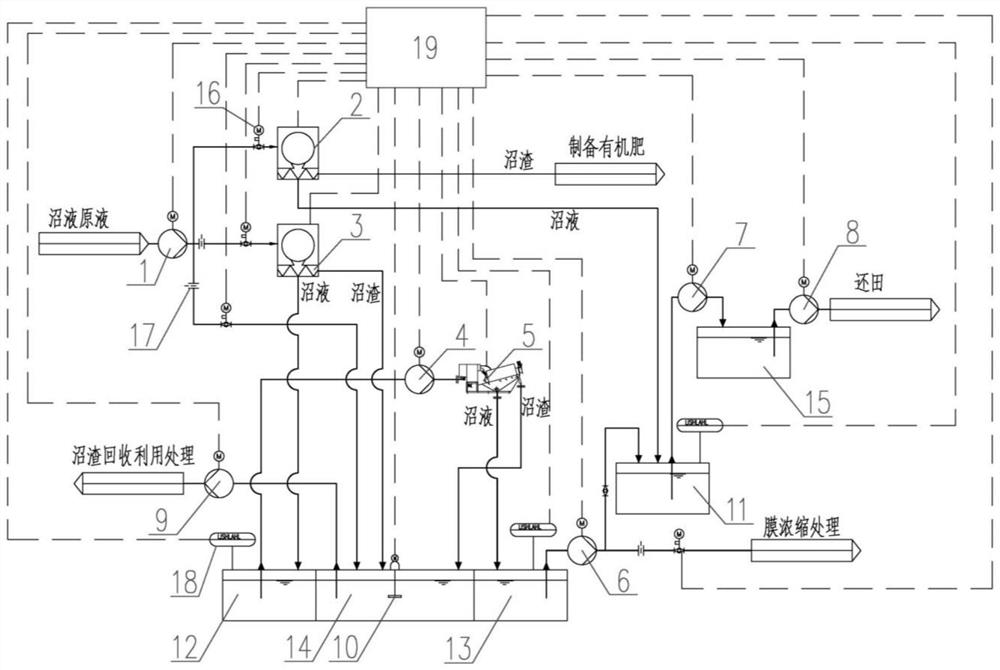

[0026] Example 1 of the present application provides a solid-liquid separation system for biogas slurry in biogas projects. The main solid-liquid separation devices are drum screw dehydrators and stacked screw dehydrators. Drum screw dehydrators are cheap and have average separation efficiency. The efficiency is high, but the price is also high; by selecting these two solid-liquid separation devices, it is economical and reasonable, and meets the requirements of this solid-liquid separation system and diversified biogas slurry treatment.

[0027] The solid-liquid separation system of the biogas project biogas slurry mainly consists of an anaerobic discharge pump 1, a first drum screw dehydrator 2, a second drum screw dehydrator 3, a second biogas slurry buffer tank delivery pump 4, and a screw stack dehydrator. Machine 5, third biogas slurry buffer tank delivery pump 6, biogas slurry delivery pump 7, field return pump 8, biogas residue buffer tank discharge pump 9, biogas resid...

Embodiment 2

[0045] Embodiment 2 of the present application provides a control method for the biogas slurry solid-liquid separation system in a biogas project. The raw liquid of the biogas slurry is divided into three paths after passing through the anaerobic discharge pump 1, as follows:

[0046] The first path is transported to the first drum screw dehydrator 2 through the regulating valve 16 for solid-liquid separation, and the separated biogas residue is processed through the belt conveyor to prepare organic fertilizer, and the biogas slurry flows into the first biogas slurry buffer pool 11 by itself.

[0047] The second path is transported to the second drum screw dehydrator 3 through the throttling orifice 17 and the regulating valve 16 for solid-liquid separation, the separated biogas residue enters the biogas residue buffer pool 14, and the biogas slurry enters the second biogas slurry buffer pool 12 by gravity. Under the control of the liquid level gauge 18, the biogas slurry in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com