Wet pre-separation process for copper-containing magnetite ore

A magnetite ore, wet-type technology, applied in the field of wet-type pre-selection of copper-containing magnetite ore, can solve problems such as waste of resources, achieve the effects of reducing the amount of grinding, enriching copper elements, and saving the cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

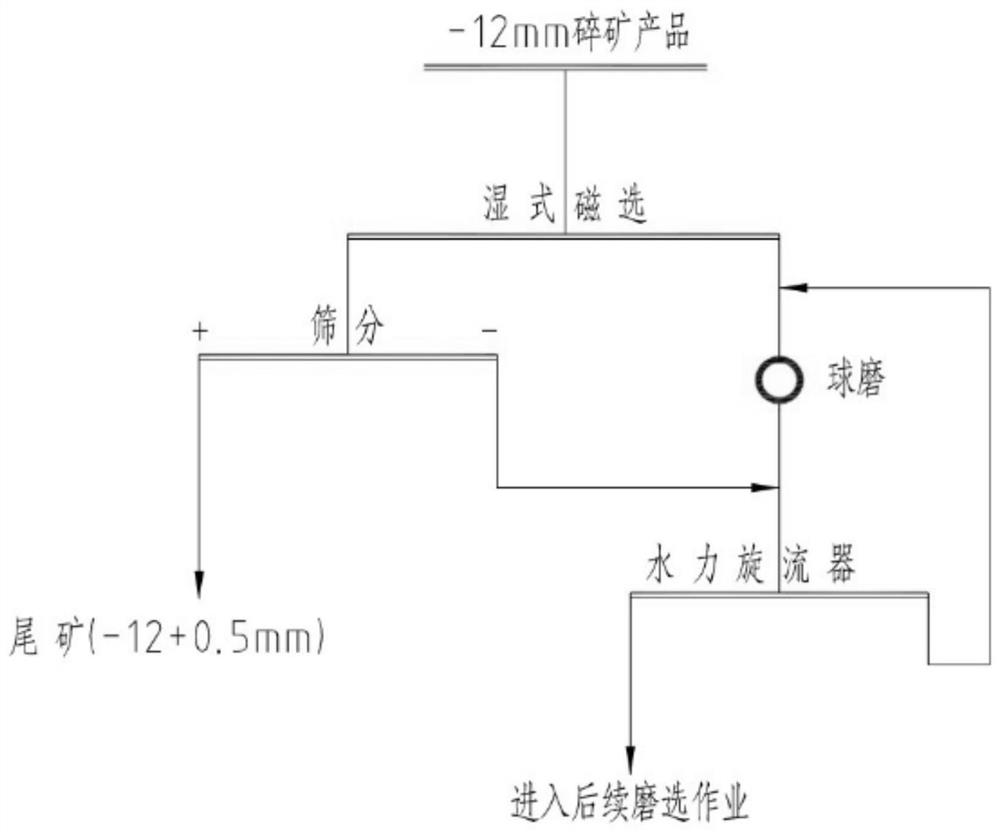

[0029] like figure 1 Shown, the iron ore of the present embodiment, the TFe grade of iron ore raw ore is 38.45%, the occupancy ratio of magnetic iron in the ore is 81.33%, and copper element content is 0.053%, and the pre-selection process is as follows:

[0030] 1. Crushing: The raw ore is crushed by the three-stage one closed-circuit crushing process, and the particle size of the crushed product is -12mm (that is, a mesh screen with a 12mm sieve), and the under-sieve is copper magnetite ore particles;

[0031] 2. Wet coarse particle separation and ball milling: perform wet magnetic separation on the screened copper magnetite ore particles, the magnetic field strength is 0.45T, the ore concentration is 35%, and the yield of magnetic separation tailings is 23.97%. (TFe content 11.78%, Cu0.10%); Obtain magnetic separation concentrate TFe grade is 46.86%; The concentrate product after magnetic separation is put into ball mill ball mill;

[0032] 3. Screening of tailings product...

Embodiment 2

[0036] like figure 1 As shown, the copper-containing magnetite ore of the present embodiment has a TFe grade of 25.32%, a magnetic iron occupancy rate of 77.85% in the ore, and a copper element content of 0.058%. The pre-selection process is as follows:

[0037] 1. Crushing: The raw ore is crushed by the three-stage one closed-circuit crushing process, and the particle size of the crushed product is -12mm (that is, a mesh screen with a 12mm sieve), and the under-sieve is copper magnetite ore particles;

[0038]2. Wet coarse particle separation and ball milling: perform wet magnetic separation on the screened copper magnetite ore particles, the magnetic field strength is 0.48T, the ore concentration is 35%, and the yield of magnetic separation tailings is 37.59%. (TFe content 10.81%, Cu0.098%); Obtaining magnetic separation concentrate TFe grade is 34.06%; The product on the sieve after the concentrate product screening after magnetic separation is given into ball mill ball mil...

Embodiment 3

[0043] like figure 1 As shown, the copper-containing magnetite ore of the present embodiment has a TFe grade of 30.66%, a magnetic iron occupancy rate of 65.85% in the ore, and a copper element content of 0.12%. The pre-selection process is as follows:

[0044] 1. Crushing: The raw ore is crushed by the three-stage one closed-circuit crushing process, and the particle size of the crushed product is -12mm (that is, a mesh screen with a 12mm sieve), and the under-sieve is copper magnetite ore particles;

[0045] 2. Wet coarse particle separation and ball mill: Wet magnetic separation is carried out on the screened copper magnetite ore particles. The magnetic separator adopts internal magnetic separation and downstream magnetic separator with a magnetic field strength of 0.5T and an ore concentration of 40. %, the yield of the magnetic separation tailings product was 30.35% (TFe content 8.87%, Cu 0.138%); the obtained magnetic separation concentrate TFe grade was 35.36%; The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com