Chain belt type atmosphere brazing furnace for soft magnetic material production and processing

A soft magnetic material and chain belt technology, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of soft magnetic material strip blocks that cannot be turned over, high defective rate, and easy to produce scale, etc., to achieve Guarantee the effect of heat treatment, avoid scale, and evenly heat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

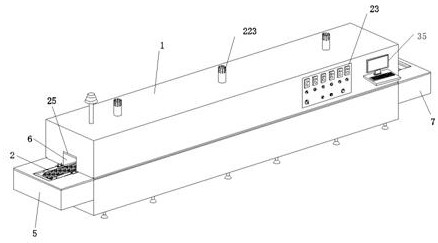

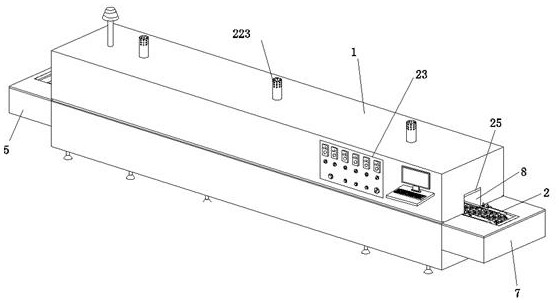

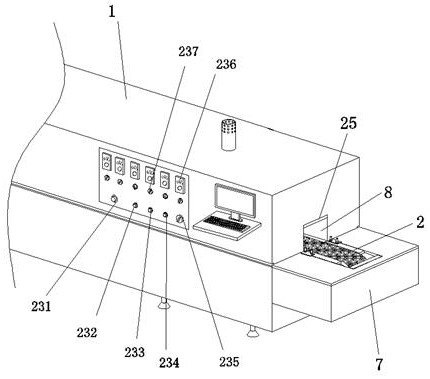

[0059] A chain-belt atmosphere brazing furnace for the production and processing of soft magnetic materials, such as figure 1 , figure 2 with Figure 5 As shown, it includes a heating furnace body 1, a mesh belt transmission structure 2, an electrical control system 3, and an ammonia decomposition protective gas supply structure 4. A loading platform 5 is fixedly installed at the left end of the heating furnace body 1, and the left side wall of the heating furnace body 1 is provided There is a feed port 6, a discharge table 7 is fixedly installed at the right end of the heating furnace body 1, a discharge port 8 is opened on the right side wall of the heating furnace body 1, and a conveyor is fixedly installed between the loading table 5 and the discharge table 7 A pair of L-shaped guide plates 10 are fixedly installed on the upper end surface of the transmission rack 9, and a mesh belt transmission structure 2 is installed on the transmission rack 9. The mesh belt transmission ...

Embodiment 2

[0066] On the basis of the first embodiment, the shape of the card slots 115 opened on the two turning plates 113 are different, such as Figure 15 As shown, the turning plate 113 is shaped like a cross as a whole.

[0067] When this embodiment is in use, the soft magnetic material strip-shaped block parts enter the card slot 115 under the transmission of the conveyor belt 201, and the stepping motor 112 will rotate 90 at the same time under the control of the electrical control system 3. °, so that the soft magnetic material strip-shaped block is turned over 90°, so that the surrounding surfaces of the soft magnetic material strip-shaped block will be sequentially turned over, so that the soft magnetic material strip-shaped block is heated more uniformly than in the first embodiment.

Embodiment 3

[0069] On the basis of the second embodiment, such as Figure 16 As shown, the entrance of the feed port 6 is provided with a pair of opposite laser sensors 24, the signal output end of the laser sensor 24 is electrically connected to the signal input end of the electrical control system 3, and the electrical control system 3 can control the turning structure 11 Operation.

[0070] When the words in this embodiment are used, the laser sensor 24 receives the signal from the soft magnetic material strip entering from the feed port 6, and the electrical control system 3 calculates the conveying speed of the conveying mesh belt 201, and then calculates the soft magnetic material When the bar reaches the inside of the card slot 115, the working time point inside the corresponding card slot 115 can then be controlled, which is more intelligent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com