Heat-preservation and heat-insulation composite cloth and preparation method thereof

A thermal insulation and fabric technology, which is applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problem of insufficient aerogel content, flying aerogel dust, hard aerogel composite materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

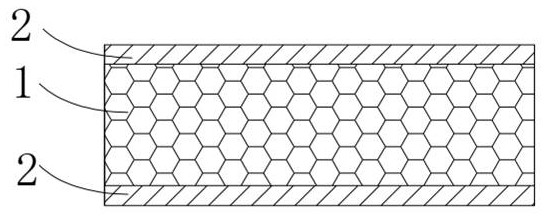

[0034] like figure 1 As shown, the present invention proposes a thermal insulation composite cloth, which includes a flexible base material layer 1 as a core layer, and a fabric layer 2 as a surface layer.

[0035] The flexible substrate layer 1 of the specific embodiment of the present application is a foamed sponge compounded with silica airgel.

[0036] A kind of thermal insulation composite fabric of the present application, which adopts open-pore structure foam sponge as the core base material, compared with the prior art that uses fiber material as the core base material, it is not only lighter, but also the composite fabric is softer and more comfortable; The foam sponge itself is porous and light. After compounding silica airgel, the airgel is combined in the pores of the foam sponge. Compared with the existing fiber material composite materials, the escape of airgel dust is greatly reduced. ; The mass proportion of silica airgel in the flexible substrate layer 1 is g...

Embodiment 2

[0048] This embodiment provides a method for preparing thermal insulation composite cloth, the preparation method comprising:

[0049] 1) Preparation: pad mesh cloth 3 on at least one side of the foam sponge;

[0050] 2) The foamed sponge lined with the mesh cloth 3 is prepared by a sol-gel method to obtain a foamed sponge filled with silica airgel;

[0051] 3) Take out the mesh cloth 3;

[0052] 4) Lay the upper fabric layer 2 on the surface of the foamed sponge compounded with silica airgel.

[0053] The applicant found that the foamed sponge itself is relatively thin, and its toughness is poor during the process of impregnating the foamed sponge coil with the sol, and it is easily deformed or even damaged. In order to improve, the present application pads mesh cloth 3 on at least one side of the foamed sponge as a support to hold the foamed sponge substrate. There is no double-sided mesh cloth, just a layer of mesh cloth to support the substrate during the production pro...

Embodiment 3

[0064] This embodiment provides another thermal insulation composite fabric and its preparation method.

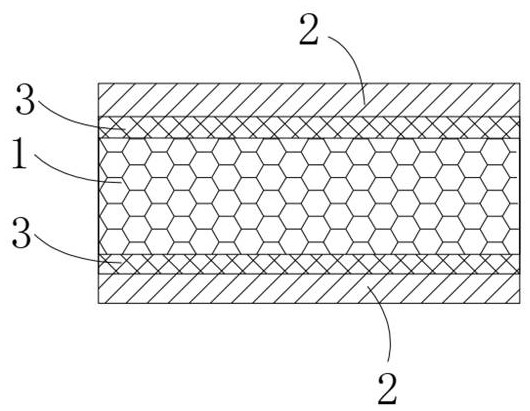

[0065] The thermal insulation composite fabric of the specific embodiment of the application, such as figure 2 As shown, the two sides of the foam sponge as the flexible base material layer 1 are pasted with mesh cloth 3 , and the mesh cloth 3 is located between the flexible base material layer 1 and the fabric layer 2 . The 3 layers of mesh cloth can be pasted on both sides of the foam sponge by hot-melt glue.

[0066] The thickness of the mesh cloth 3 is 0.05-0.3 mm, preferably 0.05-0.15 mm. Made of Polyester or Polyester material.

[0067] The thickness of the hot melt adhesive is 0.01-0.1mm, and the thickness is more preferably 0.01-0.03mm. The material of the hot melt adhesive is preferably polyurethane hot melt adhesive.

[0068] The preparation method of the thermal insulation composite cloth comprises:

[0069] 1) Preparation: Lay mesh cloth 3 on both sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com