Ardealite-based cement setting retarder as well as preparation method and application thereof

A technology of cement retarder and phosphogypsum, which is applied in the field of cement retarder, can solve the problems of low content of phosphogypsum balls, low production efficiency and high production cost, and achieve improved chemical activity, improved production efficiency and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

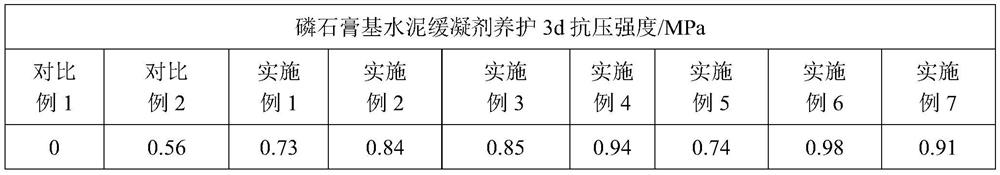

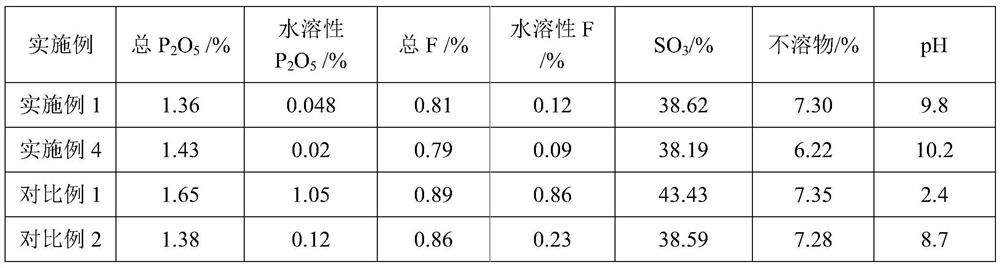

Examples

Embodiment 1

[0028] A phosphogypsum-based cement retarder, which is prepared by mixing 92% phosphogypsum, 5% slag powder, and 3% calcareous quicklime powder in mass percentage, adding water glass and continuing to stir until uniform, and forming into balls; water glass The dosage, converted into Na 2 The mass meter of O is 6% of the slag powder consumption. Among them, the attached water content of phosphogypsum is 17.2%; the CaO content in calcareous quicklime powder is ≥65%, and the sieve allowance of 90 μm is ≤7%; the slag powder is S75 grade slag powder; the modulus of water glass is 1.0.

[0029] The above-mentioned phosphogypsum-based cement retarder is specifically obtained by the following method:

[0030] 1) Mix phosphogypsum, slag powder, and calcareous quicklime powder evenly according to the above-mentioned component distribution ratio, then add water glass, continue stirring until uniform, and obtain the mixed material A;

[0031] 2) Use a disc ball forming machine to form t...

Embodiment 2

[0035] The difference between this embodiment and Example 1 is: the phosphogypsum-based cement retarder of this embodiment, by mass percentage, is mixed with 92% phosphogypsum, 5% slag powder, and 3% calcareous quicklime powder, and then added water The glass is continuously stirred until it is evenly formed into balls; the amount of water glass is converted into Na 2 In terms of the mass of O, it is 10% of the amount of slag powder; among them, the attached water content of phosphogypsum is 17.2%; the CaO content in calcareous quicklime powder is ≥65%, and the sieve allowance of 90 μm is ≤7%; the slag powder is S75 grade slag powder; the modulus of water glass is 1.0.

Embodiment 3

[0037] The difference between this embodiment and Example 1 is: the phosphogypsum-based cement retarder of this embodiment, by mass percentage, is mixed with 92% phosphogypsum, 5% slag powder, and 3% calcareous quicklime powder, and then added water The glass is continuously stirred until it is evenly formed into balls; the amount of water glass is converted into Na 2The mass meter of O is 6% of the slag powder consumption. Among them, the attached water content of phosphogypsum is 17.2%; the CaO content in calcareous quicklime powder is ≥65%, and the sieve allowance of 90 μm is ≤7%; the slag powder is S75 grade slag powder; the modulus of water glass is 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com