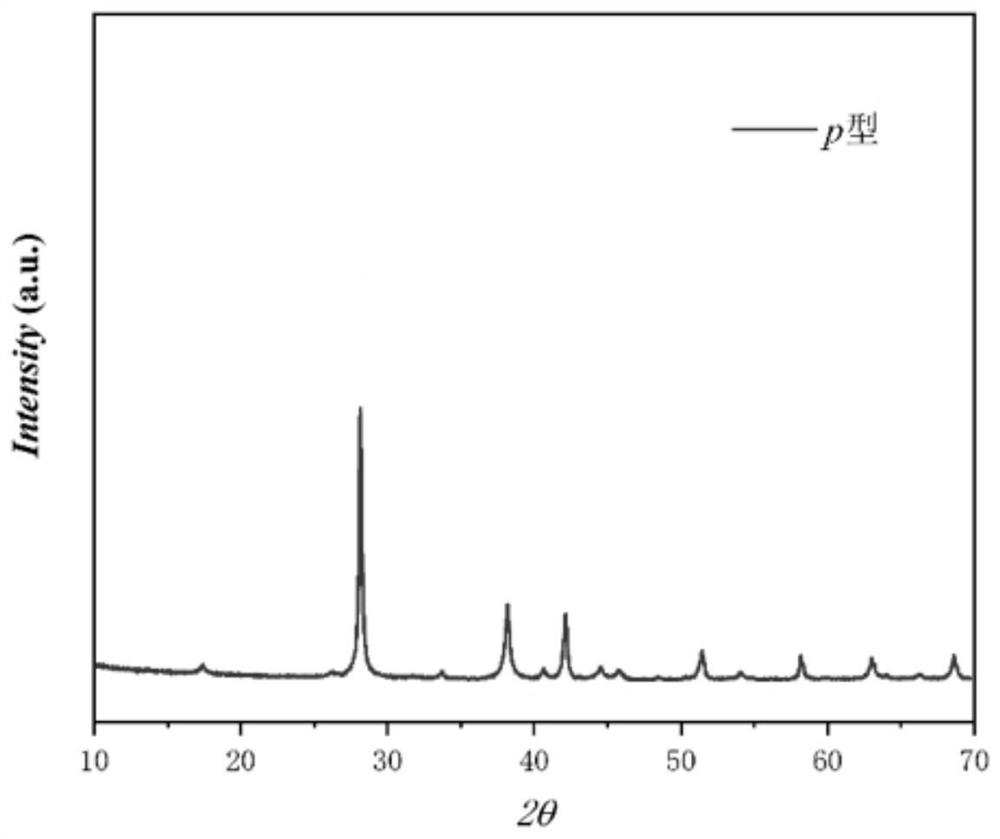

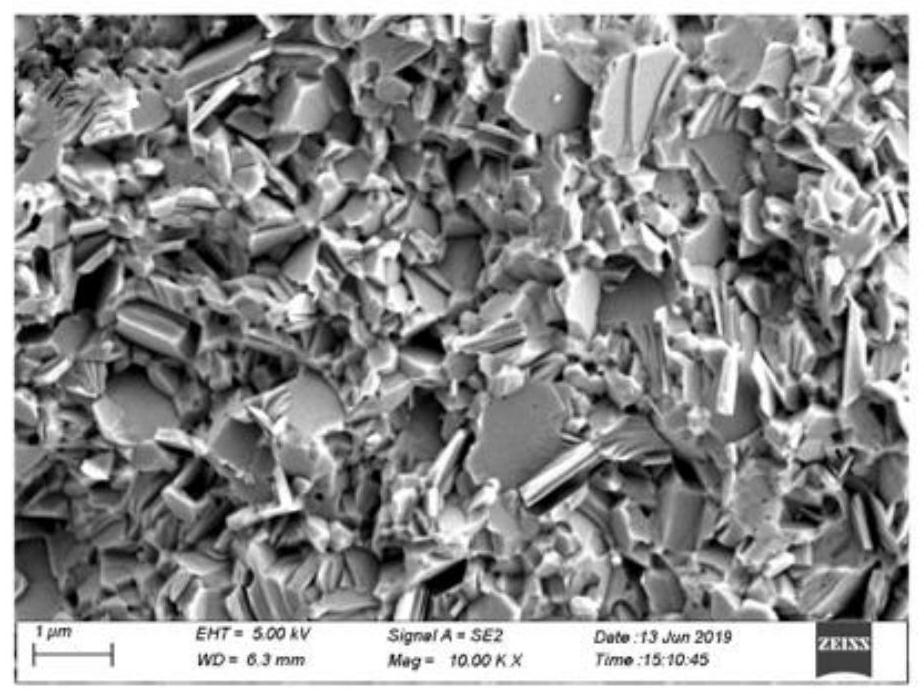

A kind of p-type bismuth telluride thermoelectric material and preparation method thereof

A thermoelectric material, bismuth telluride technology, applied in the direction of thermoelectric device node lead-out materials, etc., can solve the problems of reduced carrier mobility, reduced lattice thermal conductivity, and limited increase in ZT value, and achieves an easy-to-control composition points, high production efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare the nominal composition as Bi 0.4 Sb 1.6 Te 3 P-type bismuth telluride thermoelectric material:

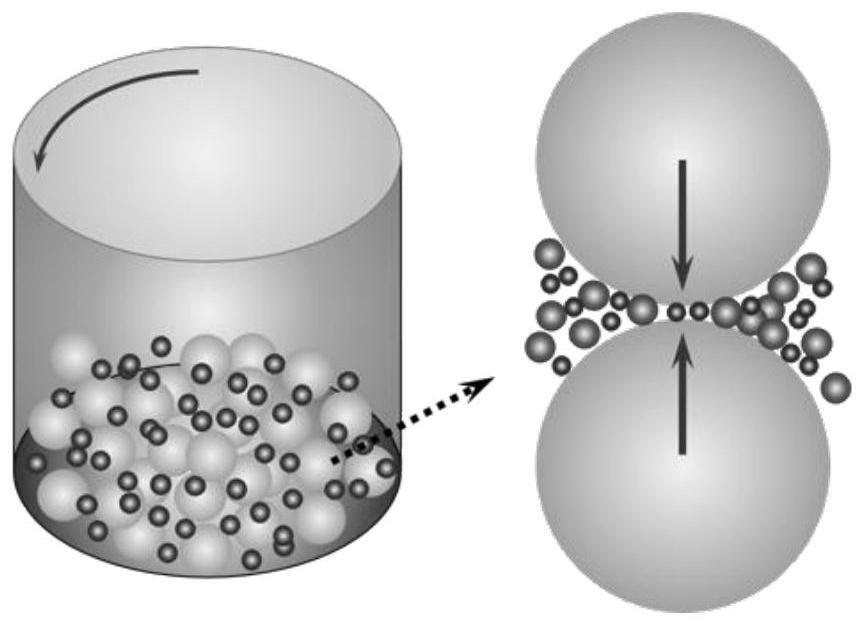

[0037](1) Using Bi and Sb with a particle size of 400 mesh and a purity of 99.99%, Te elemental powder with a particle size of 400 mesh and a purity of 99.999% as raw materials, the mass fractions of Bi, Si and Te are 12.6421wt%, 29.4701wt %, 57.8877wt% by weighing ingredients. The above-mentioned raw materials are packed in a stainless steel ball mill jar, and the stainless steel ball mill jar is placed in an Ar-protected glove box;

[0038] (2) Take out the stainless steel ball milling tank with the material loaded from the glove box, fill the ball milling tank with 5% H 2 Ar-H 2 mixed gas;

[0039] (3) Put the ball mill jar into a planetary ball mill for ball milling, each jar of ball mill raw material 15g, the ball-to-material ratio is 20:1. First mix the original powder for 1 hour under the condition of 100rmp / min. After the original powder is mixed even...

Embodiment 2

[0044] Prepare the nominal composition as Bi 0.4 Sb 1.6 Te 3 P-type bismuth telluride thermoelectric material:

[0045] (1) Using Bi and Sb with a particle size of 400 mesh and a purity of 99.99%, Te elemental powder with a particle size of 400 mesh and a purity of 99.999% as raw materials, the mass fractions of Bi, Si and Te are 12.6421wt%, 29.4701wt %, 57.8877wt% by weighing the ingredients, the above-mentioned raw materials are packed in the stainless steel ball mill tank, and the stainless steel ball ink tank is placed in the glove box protected by Ar gas;

[0046] (2) Take out the stainless steel ball milling tank with the material loaded from the glove box, fill the ball milling tank with 5% H 2 Ar-H 2 mixed gas;

[0047] (3) Put the ball mill jar into a planetary ball mill for ball milling, each jar of ball mill raw material 15g, the ball-to-material ratio is 20:1. First mix the original powder for 3 hours under the condition of 100rmp / min. After the original powd...

Embodiment 3

[0052] Prepare the nominal composition as Bi 0.4 Sb 1.6 Te 3 P-type bismuth telluride thermoelectric material:

[0053] (1) Using Bi and Sb with a particle size of 400 mesh and a purity of 99.99%, Te elemental powder with a particle size of 400 mesh and a purity of 99.999% as raw materials, the mass fractions of Bi, Si and Te are 12.6421wt%, 29.4701wt %, 57.8877wt% by weighing the ingredients, the above-mentioned raw materials are packed in the stainless steel ball mill tank, and the stainless steel ball ink tank is placed in the glove box protected by Ar gas;

[0054] (2) Take out the stainless steel ball milling tank with the material loaded from the glove box, fill the ball milling tank with 5% H 2 Ar-H 2 mixed gas;

[0055] (3) Put the ball mill jar into a planetary ball mill for ball milling, each jar of ball mill raw material 15g, the ball-to-material ratio is 20:1. First mix the original powder under the condition of 300rmp / min for 1h. After the original powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com