Continuous preparation process of nickel-based butadiene rubber and rare earth-based butadiene rubber

A butadiene rubber and preparation process technology, which is applied in the field of continuous preparation process of nickel-based butadiene rubber and rare earth-based butadiene rubber, can solve the problems of consuming a lot of time, manpower and material resources, and achieve the effect of not affecting the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

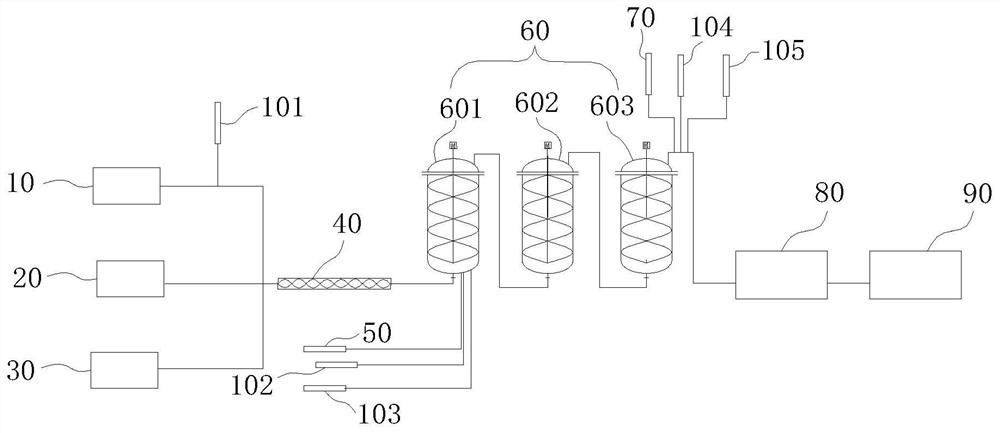

Method used

Image

Examples

Embodiment 1

[0062] Neodymium neodecanoate, diethylaluminum hydride, sesquiethylaluminum chloride and tetrahydrofuran were mixed in a molar ratio of 1:25:3:3 to obtain a rare earth catalyst, and aged at 50°C for 4 hours. Simultaneously, butadiene monomer and solvent are made into described butyl oil by refining unit, wherein, the introduction amount of butadiene monomer is 7.1m 3 / h, the amount of solvent introduced is 28m 3 / h, the concentration of butyl oil is 125.4g / L, the concentration of oxygenated compound in the control butyl oil is 8mg / kg, stop butadiene carrying water, control the water value in butyl oil to 25ppm.

[0063] Stop introducing the nickel-based catalyst, and with the introduction of 12L / h, the aged liquid of the rare-earth catalyst (Nd / butadiene monomer molar ratio is 1.0×10 -4 ) and butyl oil and 16L / h (0.03% of the mass of butadiene monomer) stabilizer mixed in a static mixer and enter the first polymerization tank. After about 2 hours, add the terminator of 113.6...

Embodiment 2

[0065] In this embodiment, on the basis of Example 1, the butadiene monomer and solvent are made into the butadiene monomer through a refining unit, wherein the introduction amount of the butadiene monomer is 8.8m 3 / h, the amount of solvent introduced is 28m 3 / h, the concentration of butyl oil is 148.3g / L, the concentration of oxygenated compounds in the control butyl oil is 8mg / kg, butadiene enters the water tank, and the control water value is 40ppm.

[0066] Stop the introduction of rare earth catalyst aging solution, stabilizer, molecular weight regulator, glue line terminator and viscosity reducer at the end of polymerization, and mix nickel and aluminum agents with butyl oil in a static mixer after aging. In the first polymerization kettle, the boron agent (boron agent diluent oil 1000L / h) is introduced into the first polymerization kettle separately, and the molar ratio of Ni, Al and B in the nickel-based catalyst is 0.9:0.31:0.9. After about 2 hours, 109 L / h (0.2% o...

Embodiment 3

[0068] In this embodiment, on the basis of Example 2, the introduction of nickel-based catalysts is stopped, and the introduction of butadiene monomer is reduced to 7.1m 3 / h, the concentration of butyl oil is 125.4g / L, the concentration of oxygenated compound in the control butyl oil is 8mg / kg, stop butadiene carrying water, control the water value in butyl oil to 25ppm. With the introduction amount of 12L / h, the aged liquid of rare earth catalyst (Nd / butadiene monomer molar ratio is 1.0×10 -4 ) is introduced, mixed with butyl oil and 16L / h (0.03% of the mass of butadiene monomer) stabilizer in a static mixer and then enters the first polymerization tank. After about 2 hours, add the terminator of 113.6L / h (2% of the mass of butadiene monomer) and the antioxidant of 88L / h (0.2% of the mass of butadiene monomer) at the outlet line of the polymerization end kettle , 24.7L / h (0.5% of the mass of butadiene monomer) viscosity reducer. According to the Mooney adjustment of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com