High-ductility optical hardened film and preparation method thereof

A ductile and hardened film technology, applied in coatings, polyurea/polyurethane coatings, etc., to prevent scratches, excellent molding effect, and good molding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

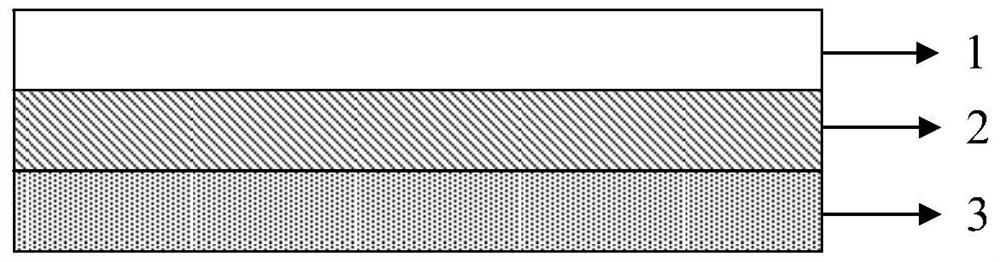

[0052] A highly ductile optical hardening film such as figure 1 As shown, it includes a high ductility hardened layer 1 , an undercoat layer 2 and a base layer 3 stacked sequentially from top to bottom.

[0053] In terms of mass percentage, the high-extensibility hardening layer 1 includes 30% of hexafunctional urethane acrylate oligomer (with better flexibility and hardness, as the main film-forming substance), methyl isobutyl ketone 63 %, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide 4%, leveling agent siloxane modified perfluoropolyether polymer (adjusting the performance after film formation) 3%.

[0054] In terms of mass percentage, the primer layer 2 includes 25% of trifunctional urethane acrylate oligomer, 69% of methyl isobutyl ketone, and 6% of 1-hydroxycyclohexyl phenyl ketone.

[0055] The substrate layer 3 is a transparent base film layer.

[0056] The transparent substrate layer 3 of the protective film provided in this embodiment has a special structure and mo...

Embodiment 2

[0065] This embodiment is basically the same as Embodiment 1, the difference is:

[0066] In terms of mass percentage, the high ductility hardening layer 1 includes 38% of hexafunctional urethane acrylate oligomer, 55% of methyl isobutyl ketone, 2,4,6-trimethylbenzoyl - Diphenylphosphine oxide 5%, leveling agent silicone modified perfluoropolyether polymer 2%.

[0067] In terms of mass percentage, the primer layer 2 includes 40% of trifunctional urethane acrylate oligomer, 53% of methyl isobutyl ketone, and 7% of 1-hydroxycyclohexyl phenyl ketone.

[0068] The preparation method of a high ductility optical hardening protective film as described above is basically the same as that of Example 1, the difference is that:

[0069] In the first coating step, the rotation speed of the coating roller is 7-8m / min, the feeding speed of the substrate is 10m / min, the oven temperature is 120°C, the curing time is 2min, and the UV curing energy is 200- 250mJ / cm 2 , the coating thickness ...

Embodiment 3

[0072] This embodiment is basically the same as Embodiment 1, the difference is:

[0073] In terms of mass percentage, the high ductility hardened layer 1 includes 43% of hexafunctional urethane acrylate oligomer, 47% of methyl isobutyl ketone, 2,4,6-trimethylbenzoyl - Diphenylphosphine oxide 5%, leveling agent silicone modified perfluoropolyether polymer 5%.

[0074] In terms of mass percentage, the primer layer 2 includes 55% of trifunctional polyurethane acrylate oligomer, 41% of methyl isobutyl ketone, and 4% of 1-hydroxycyclohexyl phenyl ketone.

[0075] The preparation method of a high ductility optical hardening protective film as described above is basically the same as that of Example 1, the difference is that:

[0076] In the first coating step, the rotation speed of the coating roller is about 10m / min, the feeding speed of the substrate is 12m / min, the oven temperature is 120°C, the curing time is 2min, and the UV curing energy is 200-250mJ / cm 2 , the coating th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com