Cut resistant glove material and cut resistant gloves and manufacturing method thereof

A manufacturing method and glove technology, which can be applied to gloves, protective clothing, textiles, and papermaking, and can solve problems such as low surface hardness and heat distortion temperature, reduced comfort of cut-resistant gloves, and easy entanglement of yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

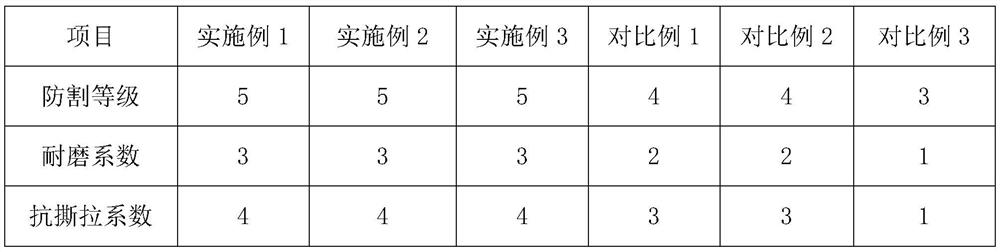

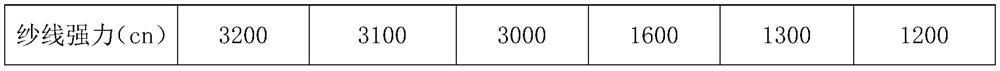

Examples

Embodiment 1

[0030] A kind of anti-cut glove, manufacturing method, comprises the following steps:

[0031] Step 1. Take the aramid yarn; impregnate the aramid yarn and the pretreatment solution according to the weight ratio of 2:1, take it out after 20 minutes, dehydrate and dry it; the composition of the pretreatment solution is: 1000g water contains 15g viscose Attachment Dow Corning Z-6121, 40g polymer synthetic lubricant SELBANAUN-T, 20g penetrant YZ-1109.

[0032] Step 2. Weigh 60g of toughening plasticizer, 110g of water-based polyurethane solution, and 800g of potassium dichromate, and mix the above solutions into a modification solution; keep the temperature at 55°C, and dip the aramid yarn after pretreatment in In the modification solution, 10 g of water-based polyurethane solution is used for every 1 g of aramid yarn, and the modification time is 20 minutes; the modified aramid yarn is washed with distilled water and then dried to obtain the modified aramid yarn; The toughening...

Embodiment 2

[0035] A kind of anti-cut glove, manufacturing method, comprises the following steps:

[0036] Step 1. Take the aramid yarn; impregnate the aramid yarn and the pre-treatment solution at a ratio of 3:1 by weight, take it out after 20 minutes, dehydrate and dry it; the composition of the pre-treatment solution is: 1000g of water contains 20g of viscose Attachment Dow Corning Z-6121, 50g polymer synthetic lubricant SELBANAUN-T, 60g penetrant YZ-1109.

[0037] Step 2. Weigh 80g of toughening plasticizer, 100g of water-based polyurethane solution, and 800g of potassium dichromate, and mix the above solutions into a modification solution; keep the temperature at 55°C, and dip the aramid yarn after pretreatment in In the modification solution, 10 g of water-based polyurethane solution is used for every 1 g of aramid yarn, and the modification time is 20 minutes; the modified aramid yarn is washed with distilled water and then dried to obtain the modified aramid yarn; The toughening ...

Embodiment 3

[0040] A kind of anti-cut glove, manufacturing method, comprises the following steps:

[0041] Step 1. Take the aramid yarn; impregnate the aramid yarn and the pre-treatment solution at a ratio of 3:1 by weight, take it out after 25 minutes, dehydrate and dry it; the composition of the pre-treatment solution is: 1000g of water contains 20g of viscose Attachment Dow Corning Z-6121, 40g polymer synthetic lubricant SELBANAUN-T, 70g penetrant YZ-1109.

[0042] Step 2. Weigh 90g of toughening plasticizer, 90g of water-based polyurethane solution, and 780g of potassium dichromate, and mix the above solutions into a modification solution; keep the temperature at 50°C, and dip the aramid yarn after pretreatment in In the modification solution, 10 g of water-based polyurethane solution is used for every 1 g of aramid yarn, and the modification time is 20 minutes; the modified aramid yarn is washed with distilled water and then dried to obtain the modified aramid yarn; The toughening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com