Conductive heating type drum dryer

A drum dryer, conduction heating technology, applied in dryers, non-progressive dryers, drying, etc., can solve the problems of not getting heat exchange heating, input and discharge, and heat conduction heating, etc., to achieve increased High conduction speed, improved utilization rate, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

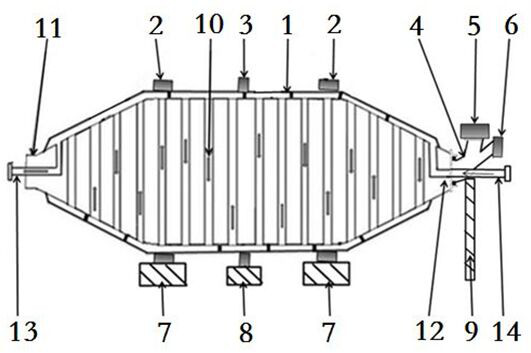

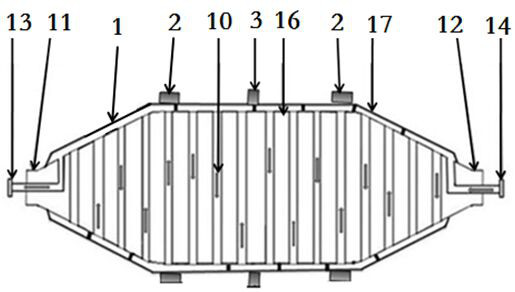

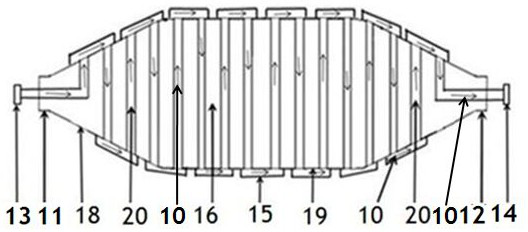

[0054] Such as figure 1 The conduction heating drum dryer shown includes a drum drying chamber 1 , a raceway 2 , a gear ring 3 , a three-way joint device 4 , an air shutoff device 5 , an exhaust device 6 , a supporting wheel 7 and a driving device 8 .

[0055] The drum drying bin 1 has an inlet 12 and an outlet 11 .

[0056] The outer diameter of the drum drying bin 1 is 1800 mm; the length of the drum drying bin 1 is 6800 mm.

[0057] The gear ring 3 and raceway 2 are installed on the bin body of the drum drying bin 1, and the gear ring 3, raceway 2 and the bin body of the drum drying bin 1 are connected and fixed as one.

[0058] The supporting roller 7 is fixedly installed on the ground, and the supporting roller 7 supports the raceway 2 of the drum drying chamber 1 .

[0059] The driving device 8 is a motor. The driving wheel of the driving device 8 occludes and drives the gear teeth of the gear ring 3 on the fixed drum drying bin 1, and the gear ring 3 drives the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com