Thermogravimetric analysis method for evaluating burning smoke of agilawood

A technology of thermogravimetric analysis and thermogravimetric analyzer, applied in the field of analysis and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of thermogravimetric analysis method that is used for the evaluation of agarwood burning smoke, comprises the following steps:

[0039] Step 1, cut 3g of Hainan artificial agarwood into small pieces, put it into a pulverizer and crush it into powder, and use it as a sample after sieving;

[0040] Step 2, weigh the sample and put 200mg in the crucible of the thermogravimetric analyzer, close the furnace body, put the furnace body of the automatic droplet continuous microextraction device, the extract solution of the automatic droplet continuous microextraction device is ethanol, and the carrier gas is nitrogen, The flow rate is 500mL / min;

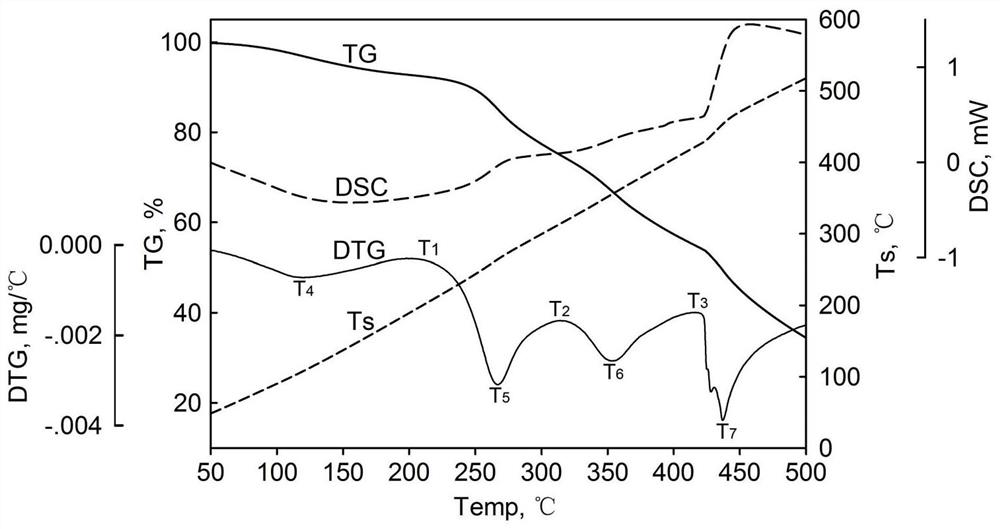

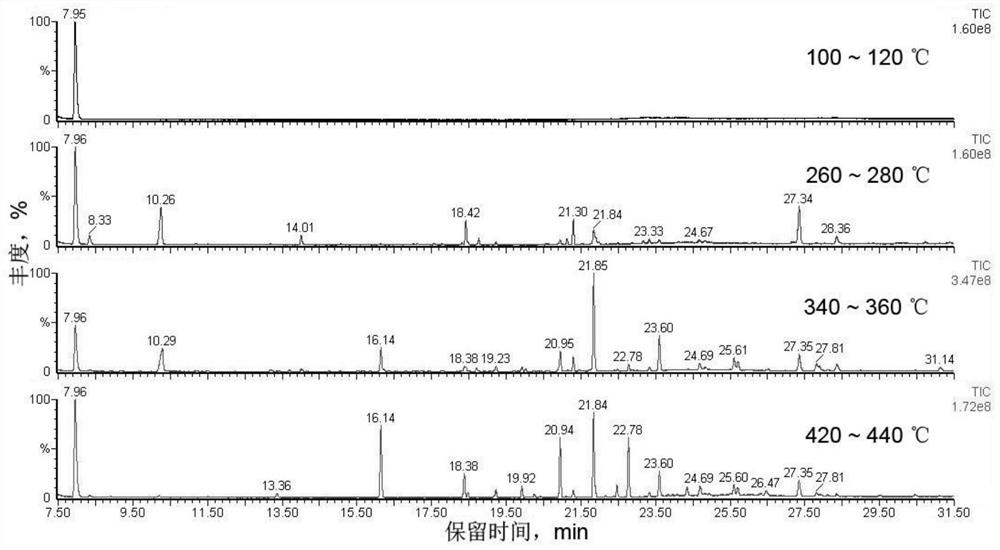

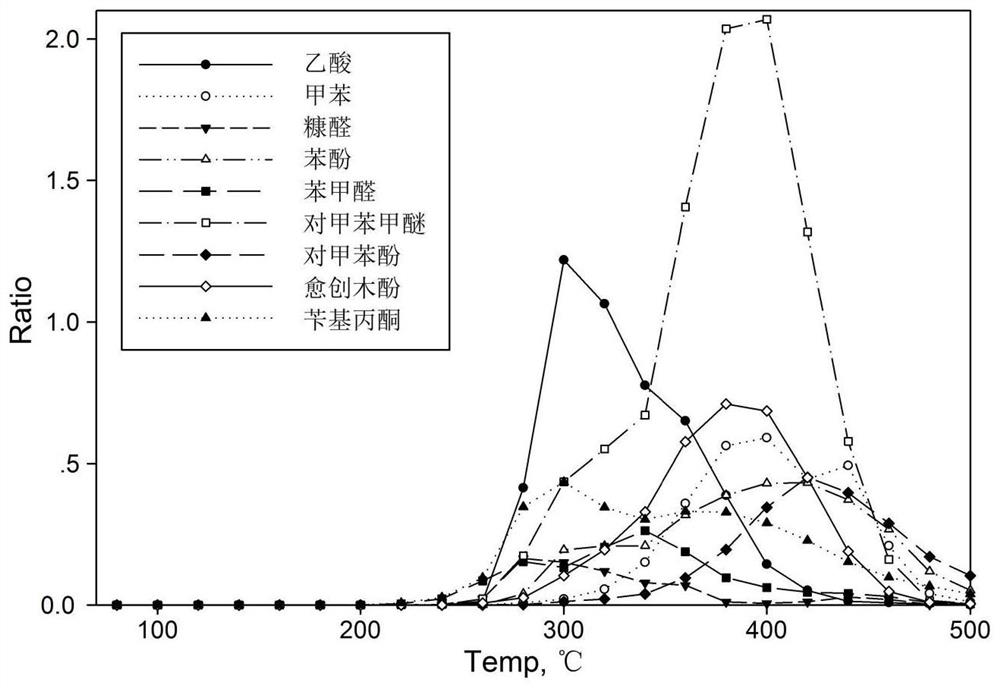

[0041] Step 3: Start the thermogravimetric analyzer, set the heating program to heat from room temperature to 600°C and keep it for 10 minutes, set the heating rate to 20°C / min, set the carrier gas to air, and the flow rate to 200mL / min, and start testing after the system is stable for 10 minutes And record the thermal analysi...

Embodiment 2

[0047] A thermogravimetric analysis method for the evaluation of agarwood burning smoke, comprising the following steps:

[0048] Step 1, cut 2g of Qinan agarwood into small pieces, put it in a pulverizer and crush it into powder, and sieve it as a sample for later use;

[0049] Step 2: Weigh the sample and place 100 mg in the crucible of the thermogravimetric analyzer, close the furnace body and place the furnace body of the automatic droplet continuous microextraction device. The extraction liquid of the automatic droplet continuous microextraction device is ethanol, the carrier gas is nitrogen, and the flow rate is nitrogen. is 900mL / min;

[0050] Step 3, start the thermogravimetric analyzer, set the heating program to heat from room temperature to 600 °C and keep it for 10 min, set the heating rate to 20 °C / min, set the carrier gas to dry air, and set the flow rate to 100 mL / min. Wait for the system to stabilize for 15 min. Detect and record thermal analysis curves;

[0...

Embodiment 3

[0056] A thermogravimetric analysis method for the evaluation of agarwood burning smoke, comprising the following steps:

[0057] Step 1, cut 3g of Hainan artificial agarwood agarwood into small pieces, put it in a pulverizer and crush it into powder, and sieve it as a sample for later use;

[0058] Step 2: Weigh the sample and place 5 mg in the crucible of the thermogravimetric analyzer, close the furnace body and place the furnace body of the automatic droplet continuous microextraction device. The extraction liquid of the automatic droplet continuous microextraction device is ether, the carrier gas is nitrogen, and the flow rate is is 100mL / min;

[0059] Step 3, start the thermogravimetric analyzer, set the heating program to heat from room temperature to 500 °C and keep it for 60 min, set the heating rate to 5 °C / min, set the carrier gas to nitrogen, and set the flow rate to 10 mL / min, and start the detection after the system is stable for 10 min. And record the thermal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com