MEMS-based multi-stationary-phase micro packed column structure and preparation method thereof

A technology of packed column and stationary phase, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of inconvenient portable instrument application, large pre-column pressure required for testing, and burden of carrier gas system, etc. Achieving the effect of being beneficial to portable applications, realizing multi-functionality, and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

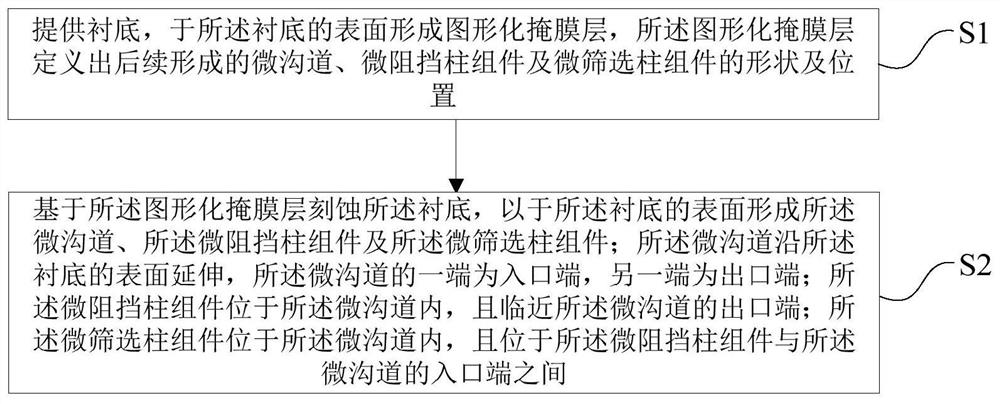

[0053] see figure 1 , the present invention provides a kind of preparation method based on MEMS (Microelectro Mechanical Systems, microelectromechanical system) multi-stationary-phase micro-packed column structure, the preparation method of described MEMS-based multi-stationary-phase micro-packed column structure can comprise the steps:

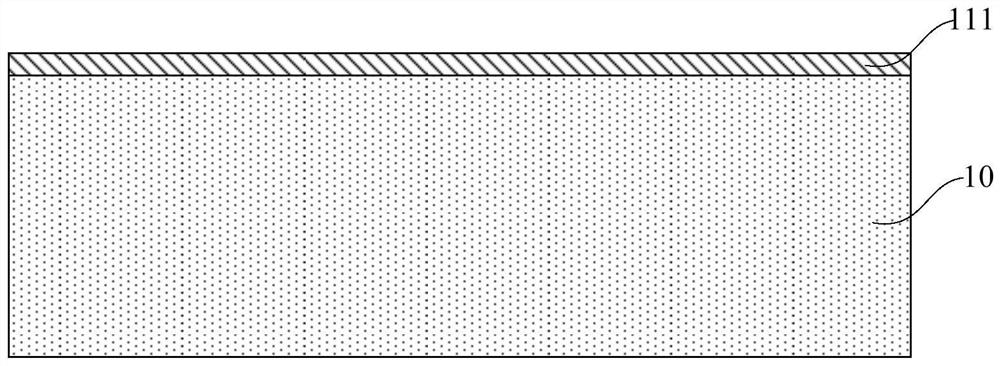

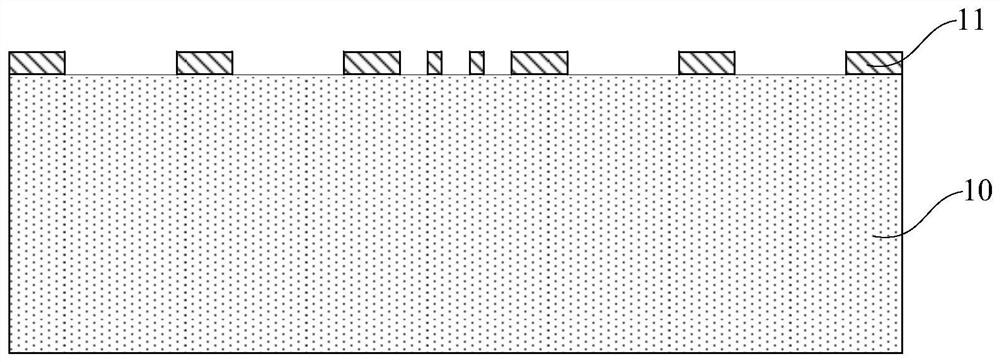

[0054] 1) providing a substrate, forming a patterned mask layer on the surface of the substrate, and the patterned mask layer defines the shape and position of the subsequently formed microchannel, micro barrier column assembly and micro screening column assembly;

[0055] 2) etching the substrate based on the patterned mask layer, so as to form the micro channel, the micro barrier pillar assembly and at least one micro screening pillar assembly on the surface of the substrate; The micro channel extends along the surface of the substrate, one end of the micro channel is an inlet end, and the other end is an outlet end; the micro blocking colu...

Embodiment 2

[0094] Please combine Figure 1 to Figure 8 refer to Figure 9 to Figure 10 , the present invention also provides a method for preparing a MEMS-based multi-stationary-phase micro-packed column structure. The preparation methods of the multi-stationary-phase micro-packed column structure of MEMS are roughly different, and the difference between the two is that in Embodiment 1, the number of prepared micro-screening column components 14 can be one, such as Figure 4 and Figure 5 Shown; And in the present embodiment, the quantity of described micro-screening column assembly 14 of preparation can be a plurality of, as Figure 9 and Figure 10 as shown, Figure 9 and Figure 10 The number of prepared micro-screening column assemblies 14 is three as an example, but in actual examples, the number of prepared micro-screening column assemblies 14 is not limited to this, and can also be two or four , five, six or even more and so on. A plurality of the micro-screening column ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com