An Upper Die of Stamping Equipment Based on PLC Control

A stamping equipment and core mold technology, applied in the field of automation, can solve the problems of unfavorable staff health, harmful gas, high equipment cost, etc., and achieve the effect of reducing processing procedures, reducing harmful gas emissions, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

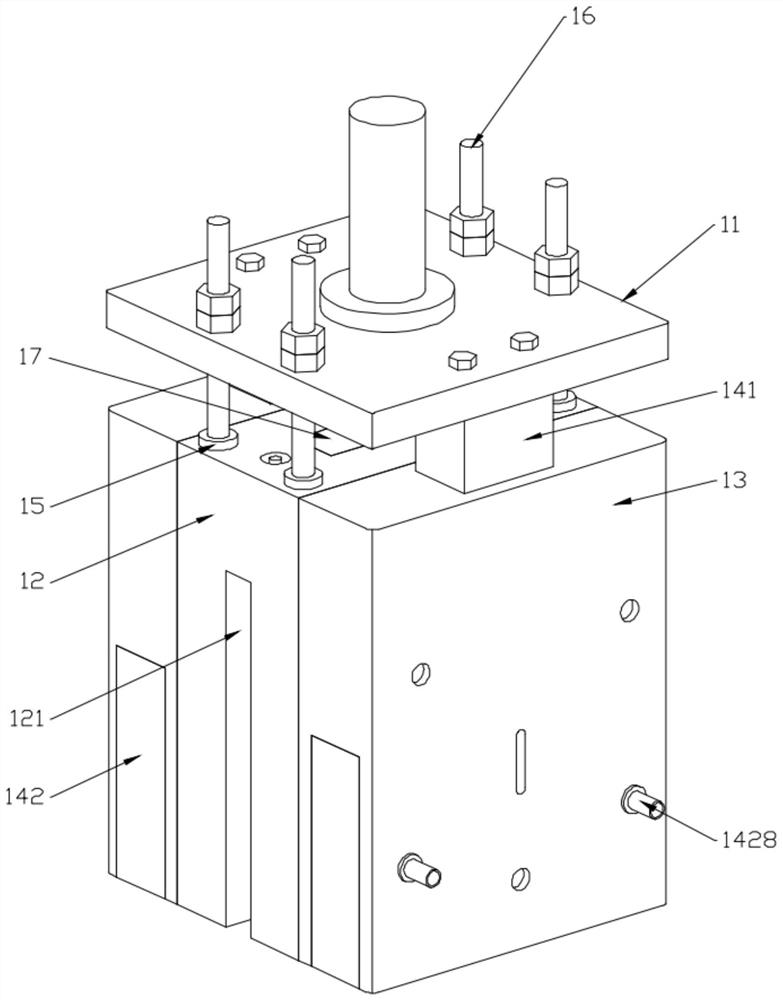

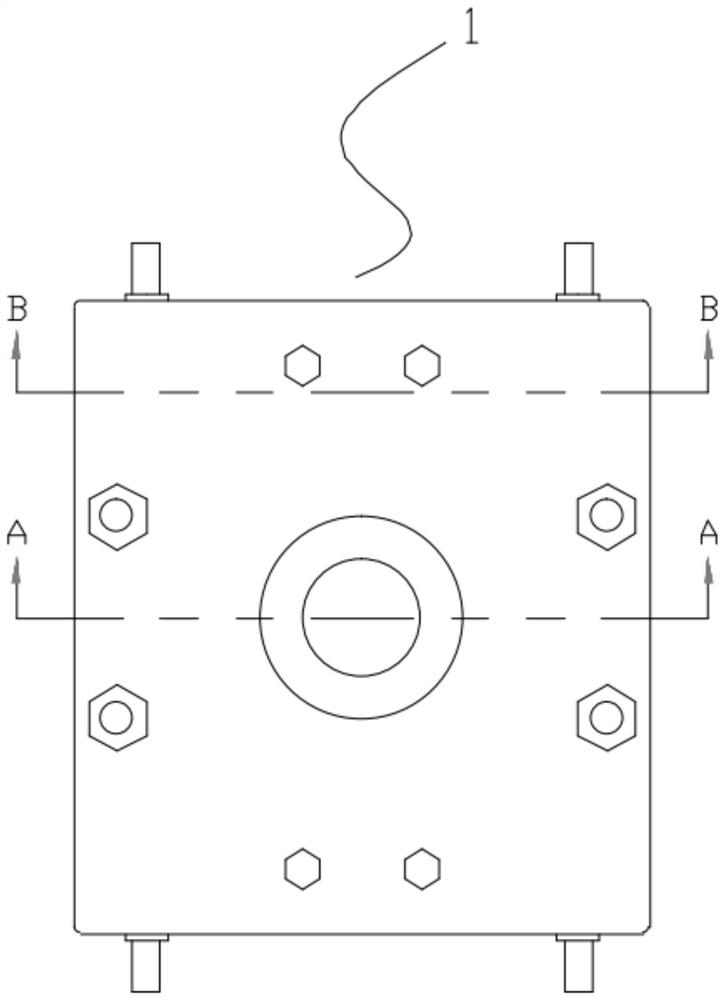

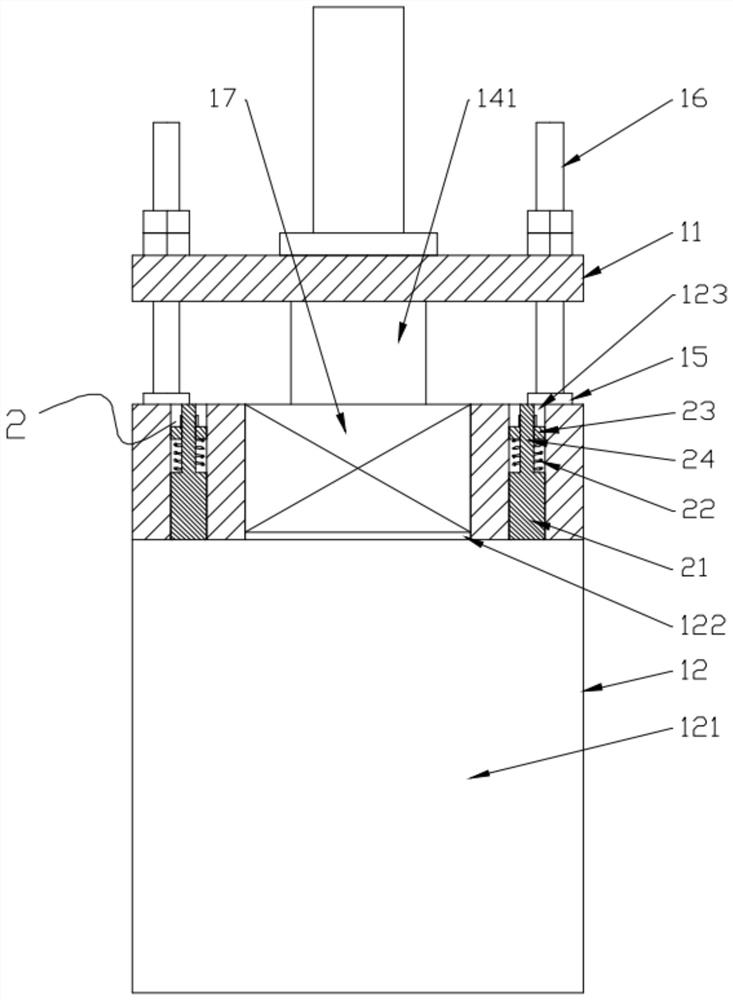

[0031] Such as Figures 1 to 12 As shown, an upper mold of a PLC-controlled stamping device includes an upper mode assembly 1 and a positive electrode conductive mechanism 4, the upper mode assembly 1 includes an upper template 11, a core mold 12, a side mold 13, and a support mechanism 14. The upper template 11 is coupled to the output of the hydraulic cylinder, and the finisher column 15 is fixed at the four corners of the upper end of the core die 12, and the upper end of the limit column 15 is fixed, and the upper template 11 slides. Connected to the guide post 16 and the lower end thereof is connected to the supporting mechanism 14, and the nut 16 is also connected to the upper template 11, which can drive the core die 12 in the upper mold plate 11, and the support me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com