Steel wire rope lubricating grease composition and preparation method thereof

A technology of lubricating grease composition and steel wire rope, applied in lubricating composition, petroleum industry, etc., can solve problems such as poor wear resistance, unsatisfactory long-term operation, unsatisfactory low temperature performance, poor product stability, etc., and achieve excellent operability and Economical, meet the temperature and life requirements, highlight the effect of high and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

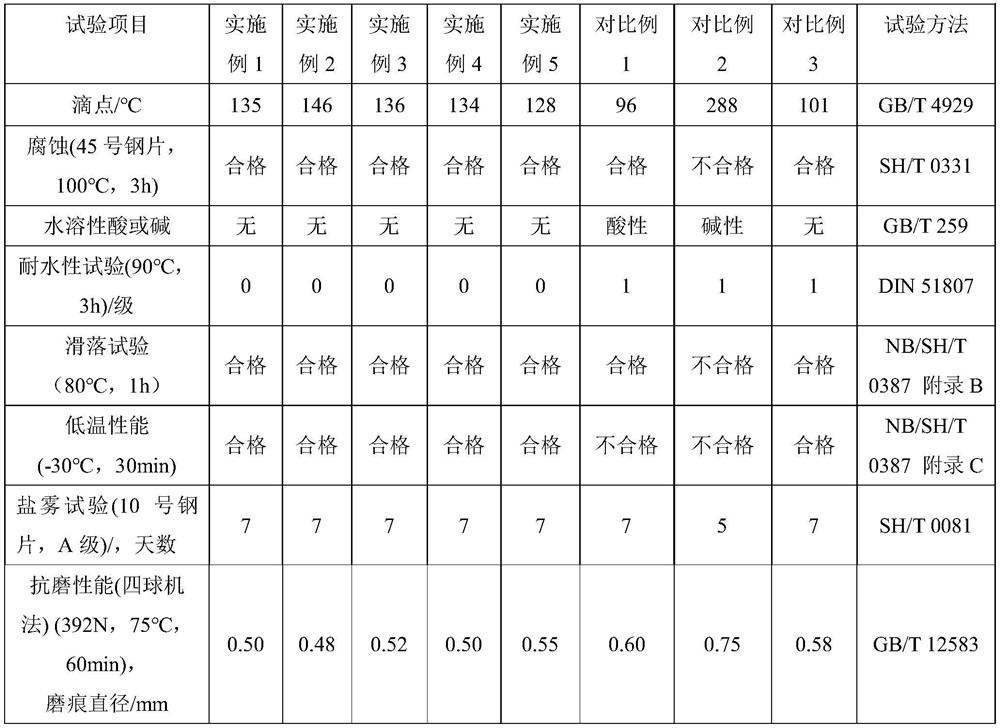

Examples

Embodiment 1

[0032] The preparation method of embodiment 1 steel wire rope grease composition

[0033] Each component is calculated by gross weight 100% in the present embodiment, is respectively as follows:

[0034] (1) Polyethylene wax: 10.5%; (2) Fatty acid: 4.6%; (3) Acetic acid: 0.8%; (4) Barium hydroxide octahydrate: 4.5%; (5) Polyisobutylene: 9.0%; (6) Extreme pressure agent: 1.5%; (7) base oil: 69.1%.

[0035] Add 94.9 grams of lauryl hydroxystearic acid, 15.8 grams of acetic acid and 1072.5 grams of paraffinic base oil 150BS into the reaction kettle, heat to 85°C, and slowly add 93.2 grams of barium hydroxide octahydrate. Heat to 90°C to start saponification, react for 60 minutes, and after saponification, raise the temperature to 125°C, add 357.5 grams of polyα-olefin synthetic oil base oil PAO40, 210.0 grams of polyethylene wax, and 180.0 grams of polyisobutylene. Continue to raise the temperature to 140°C, keep the temperature for 60 minutes and start to cool down. After the ...

Embodiment 2

[0036] The preparation method of embodiment 2 steel wire rope grease composition

[0037] Each component is calculated by gross weight 100% in the present embodiment, is respectively as follows:

[0038] (1) polyethylene wax: 8.0%; (2) fatty acid: 6.2%; (3) acetic acid: 1.0%; (4) octahydrate barium hydroxide: 5.9%; (5) polyisobutylene: 10.0%; (6) Extreme pressure agent: 2.0%; (7) base oil: 66.9%.

[0039] Add 161.0 grams of lauryl hydroxystearic acid, 24.8 grams of acetic acid and 1361.1 grams of paraffinic base oil 150BS into the reaction kettle, heat to 82°C, and slowly add 152.6 grams of barium hydroxide octahydrate. Heating to 95°C to start saponification, reacting for 90min, and then raising the temperature to 125°C after saponification, adding 388.9 grams of polyα-olefin synthetic oil base oil PAO40, 210.0 grams of polyethylene wax, and 250.0 grams of polyisobutylene. Continue to raise the temperature to 140°C, keep the temperature for 60 minutes and start to cool down...

Embodiment 3

[0040] The preparation method of embodiment 3 steel wire rope grease composition

[0041] Each component is calculated by gross weight 100% in the present embodiment, is respectively as follows:

[0042] (1) polyethylene wax: 12.0%; (2) fatty acid: 5.2%; (3) acetic acid: 0.7%; (4) octahydrate barium hydroxide: 4.7%; (5) polyisobutylene: 8.0%; (6) Extreme pressure agent: 1.0%; (7) base oil: 68.4%.

[0043] Add 156.9 grams of lauryl hydroxystearic acid, 29.1 grams of acetic acid and 1646.0 grams of paraffinic base oil 150BS into the reaction kettle, heat to 83°C, and slowly add 144.1 grams of barium hydroxide octahydrate. Heat to 100°C to start saponification, react for 75 minutes, and after saponification, heat up to 130°C, add 411.6 grams of polyα-olefin synthetic oil base oil PAO40, 360.0 grams of polyethylene wax, and 240.0 grams of polyisobutylene. Continue to raise the temperature to 135°C, keep the temperature for 40 minutes and start to cool down. After the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com