Anti-wear lubricant composition, preparation method thereof and trace lubricant prepared from the composition

A technology of anti-wear lubricants and micro lubricants, applied in the field of lubrication, can solve the problems of environmentally unfriendly sulfur and chlorine-containing additives, environmental impact, large amount of lubricant usage, etc., and achieve remarkable environmental protection effects and strong ductility Excellent elasticity and anti-friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 191.14 g (1 mol) of aminotriacetic acid, 716.52 g (2.4 mol) of isoeicosanol, 250 g of polyethylene glycol (PEG1000), and 20 g of phosphotungstic acid and place them in the reaction kettle, stir and heat to 180 ° C, and fully react for 5 hour, the reaction process is decompressed and drained twice, and after the reaction is completed, the water is decompressed to remove water; that is, an anti-wear lubricant composition.

[0035] The above-prepared anti-wear lubricant composition and water are mixed uniformly in a weight ratio of 1:2, and the mixture can be used in a micro-lubrication device.

Embodiment 2

[0037] Weigh aminotriacetic acid 191.14g (1mol), isooctanol 325.58g (2.5mol), polyethylene glycol (PEG200) 98g, phosphotungstic acid 10g and place in the reactor, stir and heat to 180 ℃, fully react for 6 hours , the reaction process is decompressed and drained twice, and after the reaction is completed, the water is decompressed to remove water; that is, an anti-wear lubricant composition.

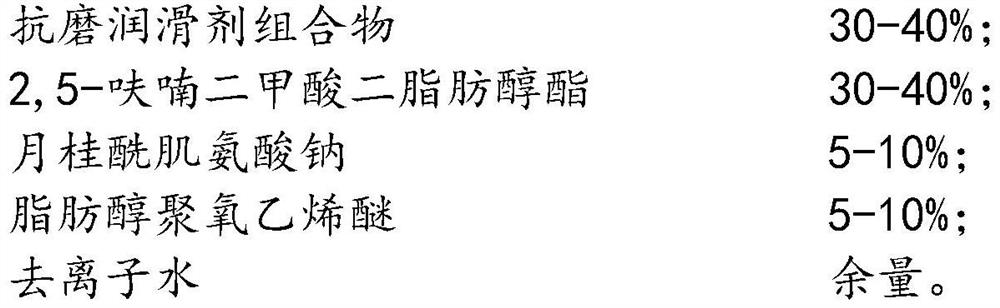

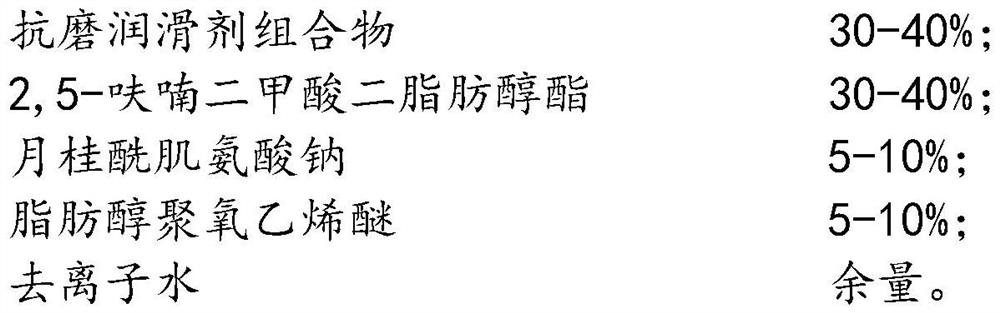

[0038] Weigh 400 g of anti-wear lubricant composition, 300 g of diisooctyl 2,5-furandicarboxylate, 100 g of sodium lauroyl sarcosinate, 50 g of fatty alcohol polyoxyethylene ether (AEO-12), and 150 g of deionized water. It is a micro-lubricant when mixed at room temperature until translucent.

[0039] The preparation method of above-mentioned 2,5-furandicarboxylic acid diisooctyl ester:

[0040] 156.09g (1mol) of 2,5-furandicarboxylic acid, 286.51g (2.2mol) of isooctanol and 8g of dilute sulfuric acid (10%) were added to the reaction kettle, and the reaction was carried out at a reaction...

Embodiment 3

[0042] Weigh aminotriacetic acid 191.14g (1mol), isodecyl alcohol 316.56g (2mol), polyethylene glycol (PEG400) 150g, phosphotungstic acid 7g and place in the reactor, stir and heat to 200 ℃, fully react for 5 hours, During the reaction process, the water is decompressed and drained once, and after the reaction is completed, the water is decompressed to remove water; that is, an anti-wear lubricant composition.

[0043] Weigh 300 g of anti-wear lubricant composition, 400 g of diisodecyl 2,5-furandicarboxylate, 50 g of sodium lauroyl sarcosinate, 100 g of fatty alcohol polyoxyethylene ether (AEO-10), and 150 g of deionized water. It is a micro-lubricant when mixed and stirred at room temperature until transparent.

[0044] The preparation method of above-mentioned 2,5-furandicarboxylic acid diisodecyl ester: add 2,5-furandicarboxylic acid 156.09g (1mol), isodecyl alcohol 316.56g (2mol), 2g phosphotungstic acid in the The reaction is carried out at a reaction temperature of 180°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com