Patents

Literature

62results about How to "Improves and stimulates lubricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

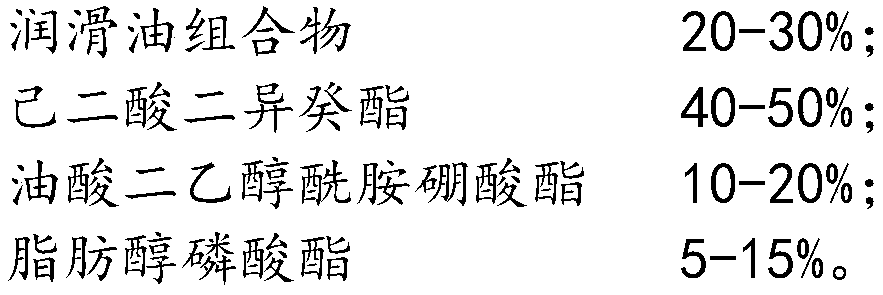

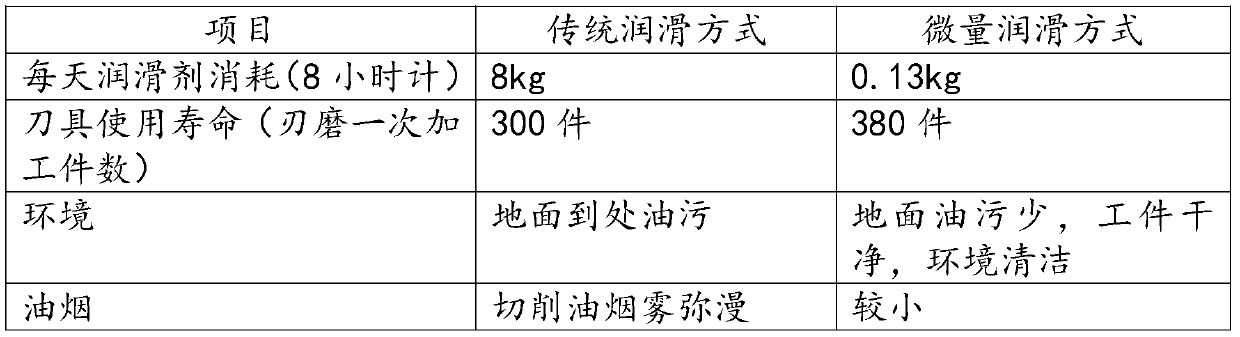

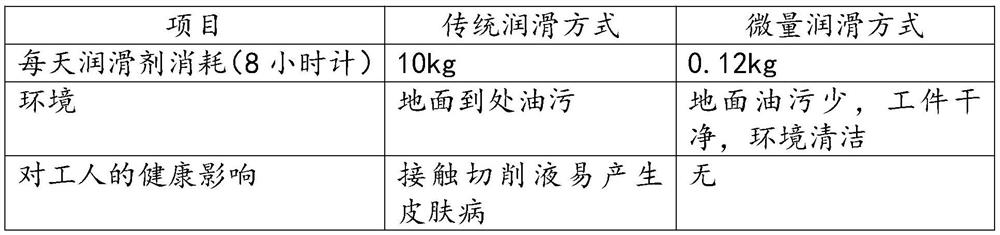

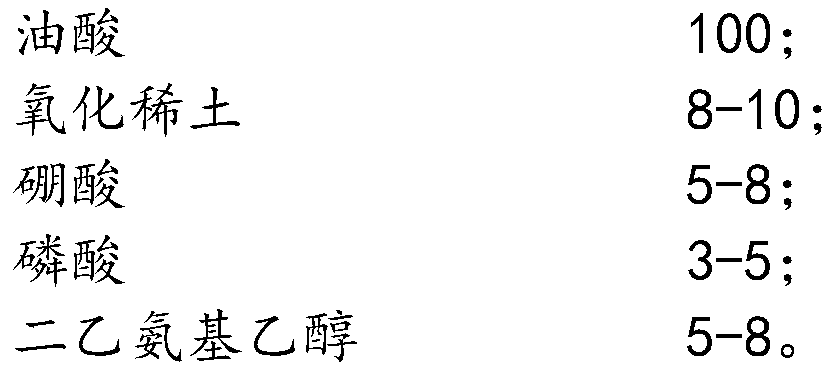

Lubricant composition, preparation method thereof and trace amount of cutting fluid prepared through composition

ActiveCN105695042AGood extreme pressure and anti-wear propertiesReduce usageAdditivesPolyesterSolubility

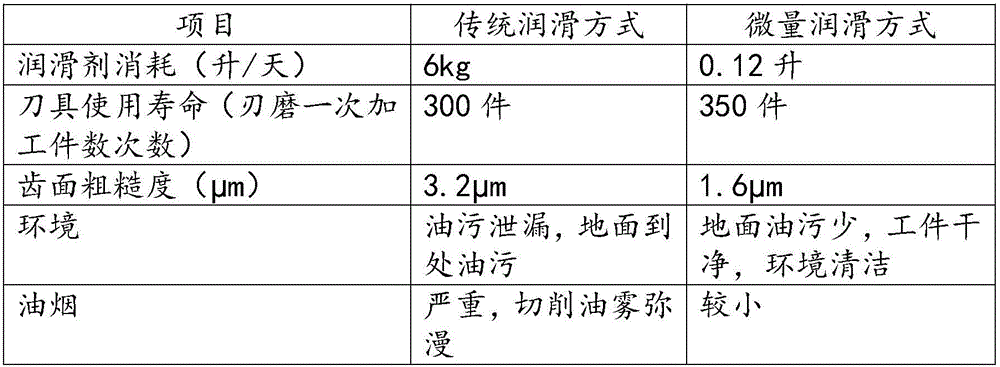

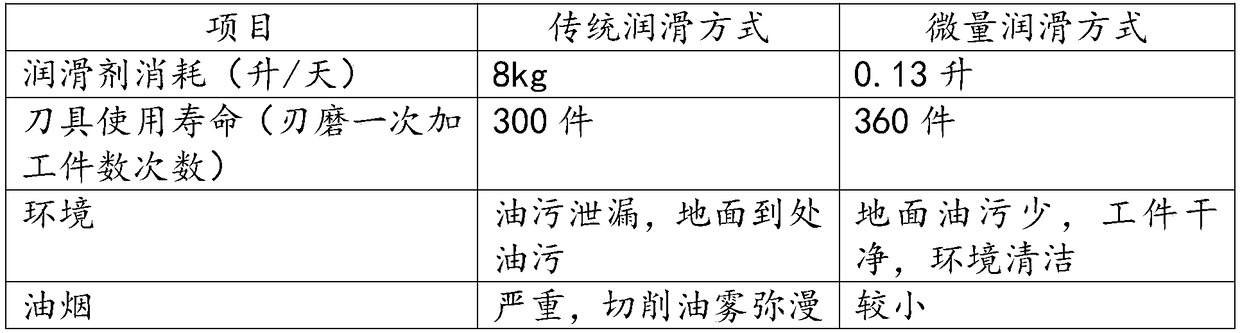

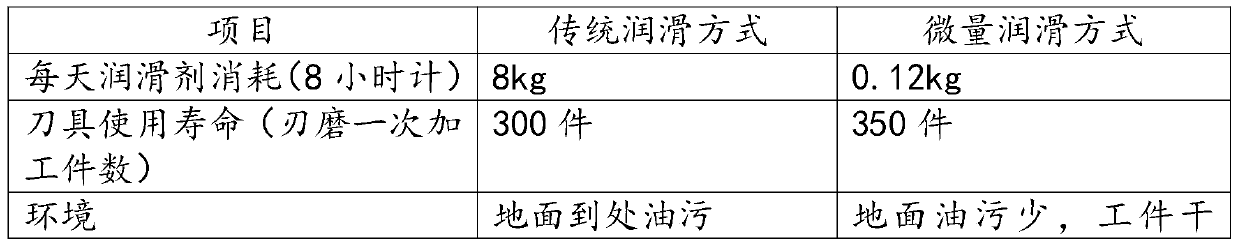

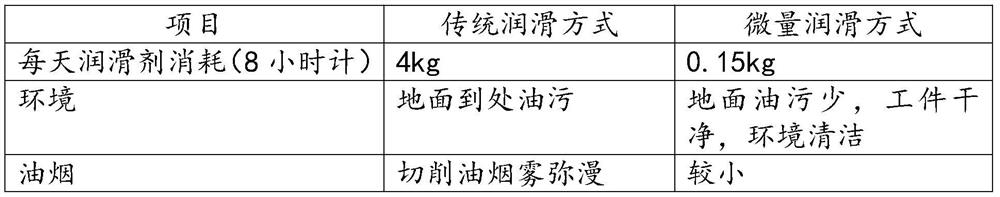

The invention provides a lubricant composition. The lubricant composition is characterized by being prepared from saccharose, dicarboxylic acid, fatty acid and polyethylene glycol with the mole ratio being 1:1-1.5:1-1.5:1-3. According to the lubricant composition, due to the fact that the synthesized polyester compound has multiple vacancy -OH, the lubricant composition can effectively adhere to the metal surface, has the excellent lubricity, good extreme pressure antiwear property and good water solubility, is the excellent surfactant, can completely or partially replace traditional extreme pressure anti-wear reagent comprising chlorine, sulphur and phosphorus to be used in a micro amount of cutting fluid, and the requirements of metal machining for lubrication cooling, extreme pressure wear resistance and rust prevention can be met through a micro amount of cutting fluid; the cutting liquid is used in cooperation with a micro lubricating device, the use amount of the cutting fluid can be reduced by 90% or above, and the effects of energy conservation, emission reduction and environmental protection are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Polysucrose fatty acid ester, preparation method thereof and application thereof to preparation of micro-scale lubricating oil

ActiveCN105732968AReduce usageImprove the lubrication effectLubricant compositionSucroseMetalworking

The invention provides polysucrose fatty acid ester which is characterized by comprising or being prepared from sucrose, dicarboxylic acid and fatty acid at a mole ratio of 1:(1-1.5):(1-2). Due to the rich vacancy-OH, the polysucrose fatty acid ester provided by the invention can be effectively adhered to surfaces of processed metals, is excellent in lubrication property, extreme pressure antiwear property and rusting resistance, and can completely or partially replace conventional extreme pressure antiwear agents used in micro-scale lubricating oil, and only the micro-scale lubricating oil can meet the requirements of lubrication cooling, extreme pressure antiwear property and rusting resistance in metal processing, and when the polysucrose fatty acid ester is used with a micro-scale lubricating device, the use amount of cutting fluid can be reduced by more than 95%, and remarkable effects of energy conservation, emission reduction and environmental protection can be achieved.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

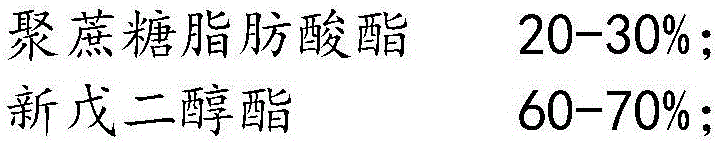

Phosphorus-boron-nitrogen-containing composition trace lubricating oil and preparation method thereof

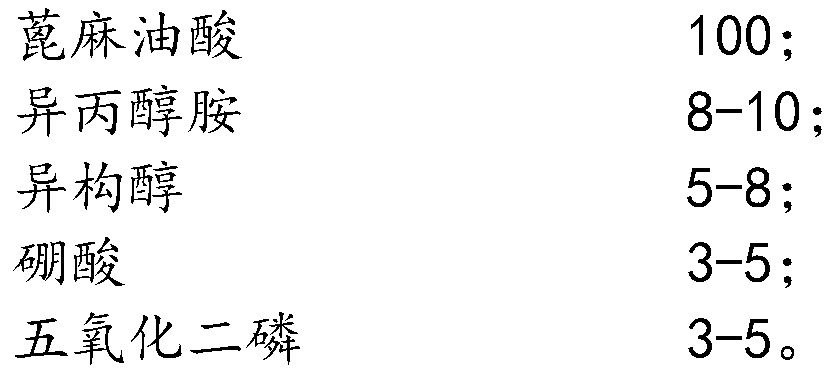

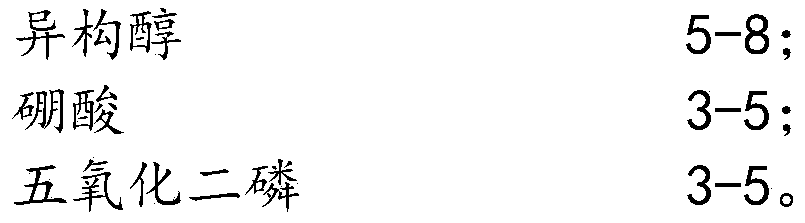

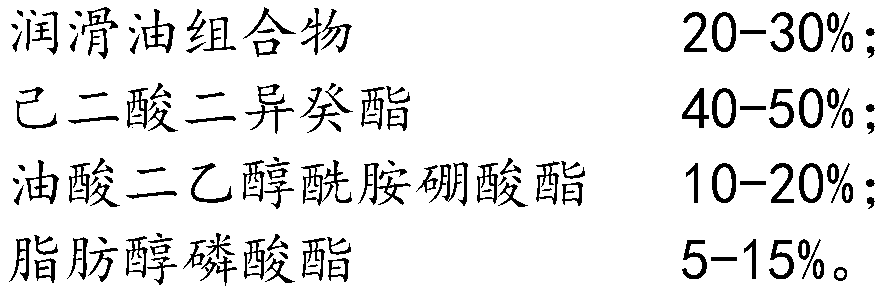

The invention provides a lubricating oil composition, which is characterized in that the lubricating oil composition provided by the invention is prepared from the following components (by weight): 100 parts of ricinoleic acid, 8-10 parts of isopropanolamine, 5-8 parts of isomeric alcohol, 3-5 parts of boric acid and 3-5 parts of phosphorus pentoxide. The lubricating oil composition prepared by adopting the preparation method is a B-P-N type friction modifier and an antirust agent, and is good in degradability. The invention also provides trace lubricating oil containing the above lubricatingoil composition, and the trace lubricating oil is characterized by being prepared from the following components (by weight): 10-20% of the lubricating oil composition, 70-80% of diisodecyl adipate and10-20% of polysucrose fatty acid ester. The trace lubricating oil prepared by the invention can meet the requirements of lubrication cooling, extreme pressure wear resistance and rust prevention in metal processing; and the use amount of a lubricant can be saved by more than 95% by matching with a minimal quantity lubricating device, and the effects of energy conservation, emission reduction andenvironmental protection are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Environment-refreshing lubricating oil and preparation method

ActiveCN112625782AImprove the lubrication effectEliminate odorLubricant compositionTrimethylolpropaneMethyl palmoxirate

The invention provides an environment-refreshing lubricating oil composition which is characterized by being prepared from terpilenol, malic acid and phosphorus pentoxide, and the molar ratio of terpilenol to malic acid is 2-2.1: 1. The weight of phosphorus pentoxide is 0.5-1% of the total weight of terpilenol and malic acid. The environment-refreshing lubricating oil composition prepared by adopting the preparation method is good in lubricating property and biodegradable, a small amount of decomposer terpilenol / alkene can refresh the environment and eliminate peculiar smell in the processing process, and the environment-refreshing lubricating oil composition also has certain extreme-pressure anti-wear property. The invention also provides environment-refreshing lubricating oil containing the environment-refreshing lubricating oil composition. The environment-refreshing lubricating oil is prepared from the following components in percentage by weight: 10-20% of the environment-refreshing lubricating oil composition; 65-75% of trimethylolpropane trioleate; and 10-20% of castor oil borate diethanolamine salt.

Owner:涵麟化学科技(上海)有限公司

Environment-friendly degradable minimal quantity lubricating oil and preparation method thereof

The invention provides lubricating oil composition. The lubricating oil composition is characterized by being prepared from sorbitol and dimer acid in a molar ratio of 1:2-3. The lubricating oil composition has relatively large molecular weight and good lubricity, extreme pressure antiwear property, antirust property and biodegradability, can completely or partially replace the traditional extremepressure antiwear agent containing chlorine, sulfur and phosphorus to be used in environment-friendly degradable minimal quantity lubricating oil, and a small amount of the environment-friendly degradable minimal quantity lubricating oil can meet the lubrication cooling, extreme pressure antiwear and antirust requirements of metal processing; by matching with a minimal quantity lubrication device, consumption of cutting oil can be saved by 95% or higher, and the effects of energy conservation, emission reduction and environmental protection are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

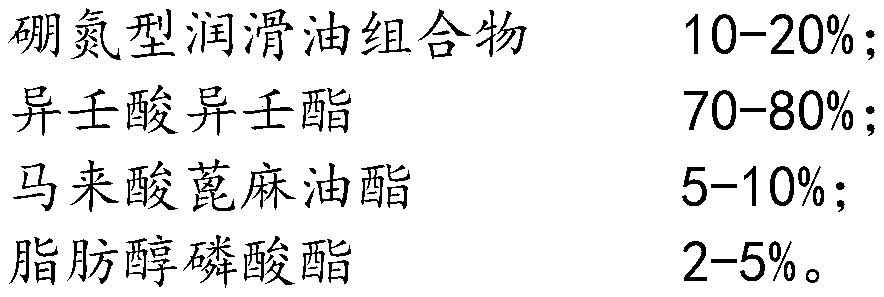

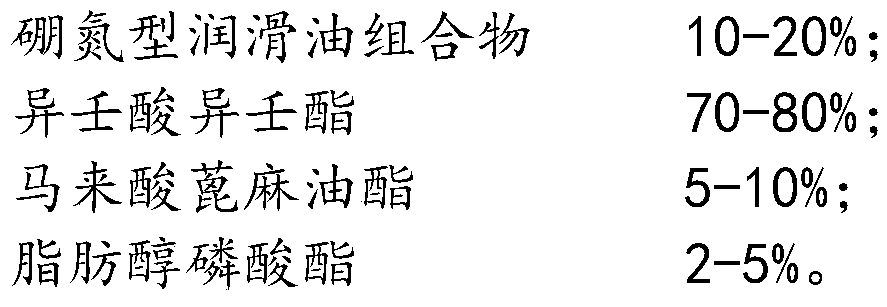

Boron-nitrogen type lubricating oil composition, preparation method thereof, and trace lubricating oil prepared from composition

ActiveCN110144254APromote degradationImprove the lubrication effectAdditivesPhosphateIsononyl Isononanoate

The invention provides a boron-nitrogen type lubricating oil composition, which is prepared from dimer acids, triethanolamine, and boric acid; wherein the mole ratio of dimer acids to triethanolamineis 0.5-1.5:1; and the mole ratio of triethanolamine to boric acid is 2-3:1. The prepared boron-nitrogen type lubricating oil composition can be used as a B-N type extreme pressure anti-wear agent andan antirust agent and has a good degradable property. The invention provides a trace lubricating oil prepared from the boron-nitrogen type lubricating oil composition. The trace lubricating oil also comprises iso-nonyl iso-nonanoate, castor oil maleate, aliphatic alcohol phosphate, and the like. The prepared trace lubricating oil can satisfy the requirements on the lubricating performance, coolingperformance, extreme pressure anti-wear performance, and antirust performance in metal processing. Under the assistance of a trace lubricating device, the using amount of the lubricating agent is reduced by 95% or more. The energy consumption and emission are reduced, and the environment protection effect is prominent.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Lubricating oil composition, preparing method thereof and near-dry processing lubricating oil prepared from composition

ActiveCN110205189AExtended service lifeHigh molecular weightLubricant compositionMetalworkingButenedioic acid

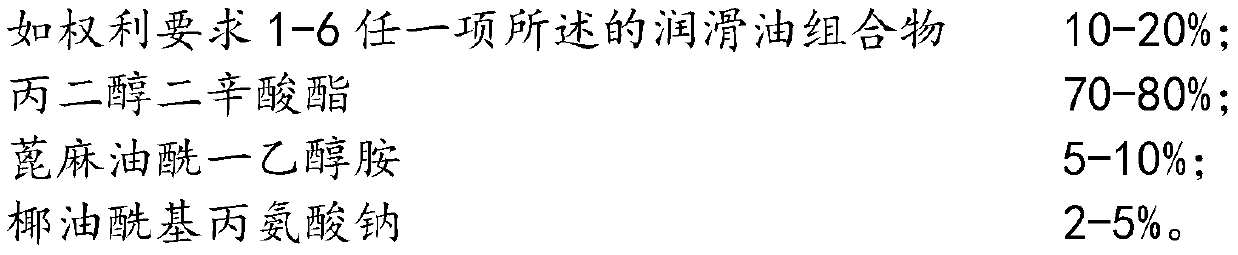

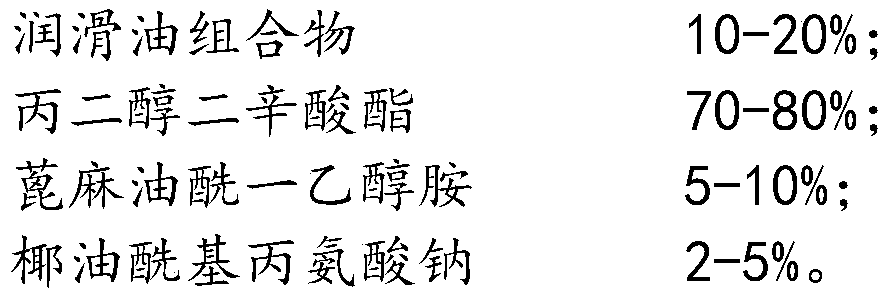

The invention provides a lubricating oil composition. The lubricating oil composition is characterized by being prepared from castor oil, butenedioic acid and rare earth oxide, wherein the mole ratioof the castor oil to the butenedioic acid is 1:1-1:1.5, and the rare earth oxide accounts for 0.1-0.5% of the weight of the composition, and is preferably one of lanthanum oxide and cerium oxide or amixture of the lanthanum oxide and cerium oxide. The invention provides a near-dry processing lubricating oil containing the lubricating oil composition. The near-dry processing lubricating oil is characterized by being prepared from, by weight, 10-20% of the lubricating oil composition, 70-80% of propylene glycol dicaprylate, 5-10% of ricinoleic acid-glycollic amide and 2-5% of sodium cocoyl alaninate. The near-dry processing lubricating oil prepared from the lubricating oil composition can meet the requirements of metal processing for lubricating cooling, extreme-pressure wear resistance andrust prevention. When the near-dry processing lubricating oil is used in cooperation with a near-dry cutting lubricating device, the use quantity of a lubricant can be saved by 95% or above, and theeffects of energy conservation and emission reduction and environmental protection are significant.

Owner:上海贝能环保科技有限公司

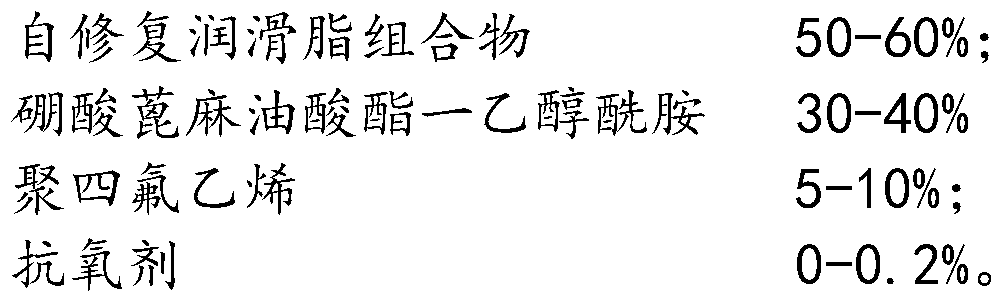

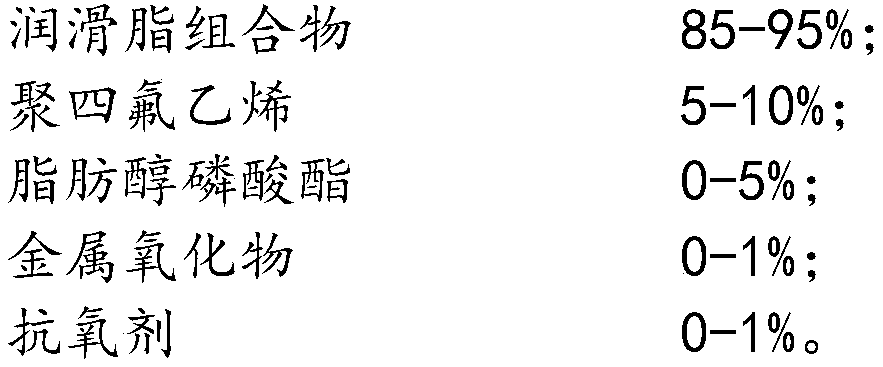

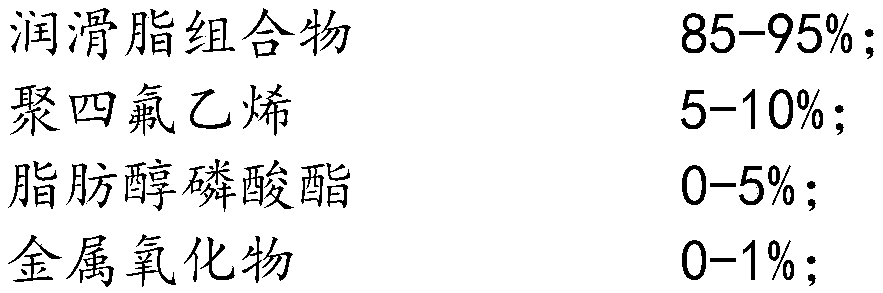

Environment-friendly self-repairing lubricating grease and preparation method thereof

ActiveCN110257141AGood extreme pressure and anti-wear propertiesGood chemical stabilityLubricant compositionPolytetrafluoroethyleneAntioxidant

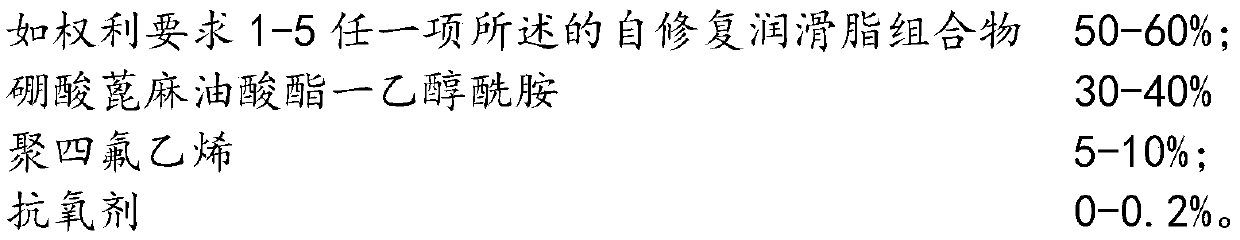

The invention provides a self-repairing lubricating grease composition, which is characterized by comprising castor oil and butenedioic acid, and the molar ratio of castor oil to butenedioic acid is 1:1-1.5. The self-repairing lubricating grease composition also comprises a rare earth oxide, wherein the rare earth oxide accounts for 0.1-0.5 wt% of the components. The self-repairing lubricating grease composition has a complex cross-linked structure, relatively large molecular weight and good lubricity and extreme pressure wear resistance; wherein the rare earth oxide not only can be used as a catalyst in the reaction process, but also exists in the composition in the form of organic neodymium, can form an iron-neodymium compound with certain magnetism with metal iron in the use process, and can automatically fill and repair tiny cracks on the surface of a friction pair. The invention further discloses the environment-friendly self-repairing lubricating grease prepared from the self-repairing lubricating grease composition, boric acid ricinoleate monoethanolamide, polytetrafluoroethylene, an antioxidant and the like.

Owner:上海源育节能环保科技有限公司

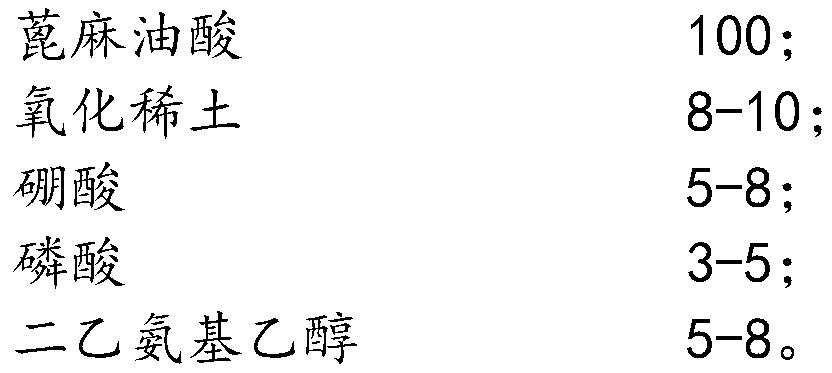

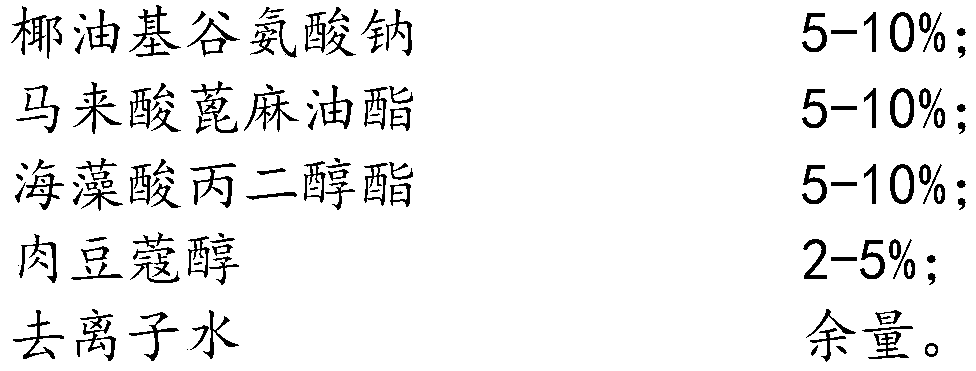

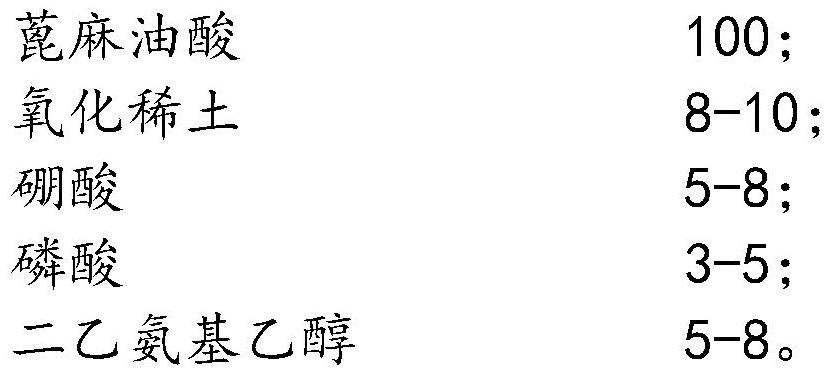

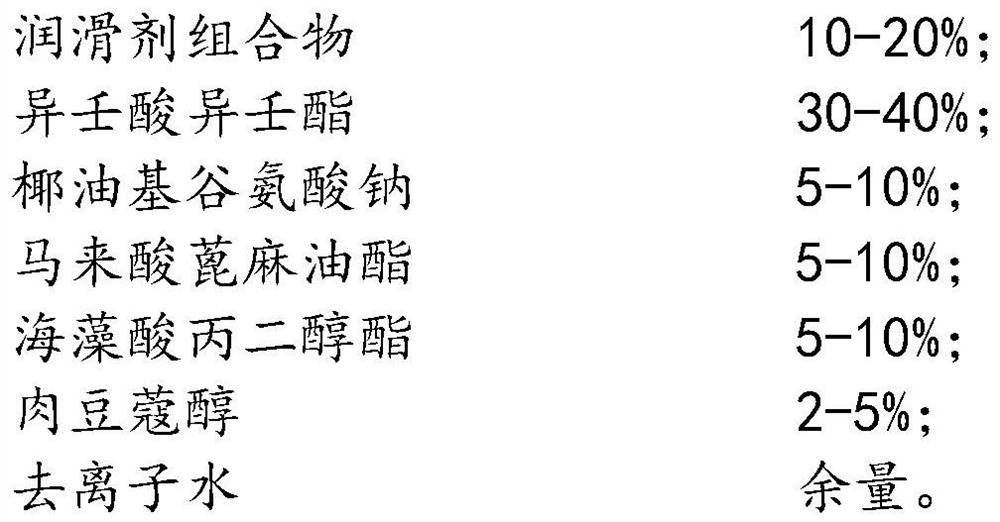

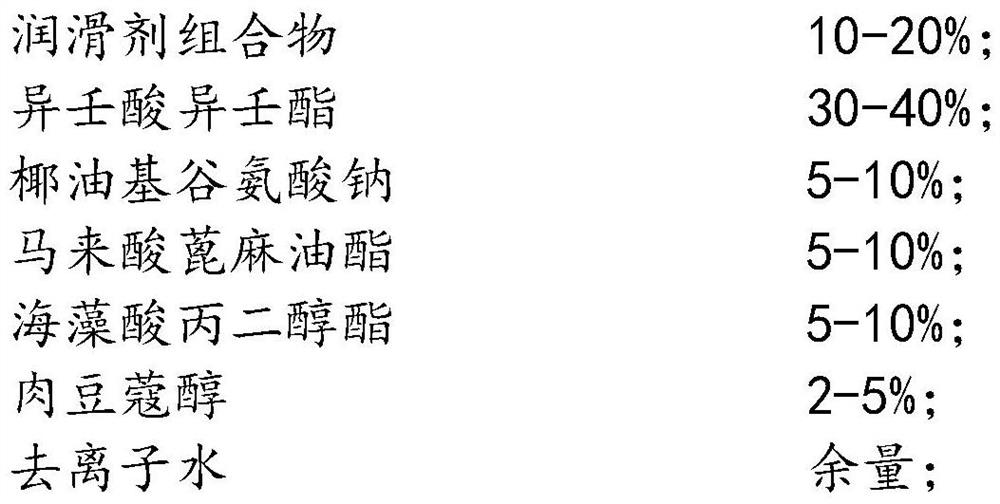

Lubricant composition and preparation method thereof and preparation of trace lubricant by composition

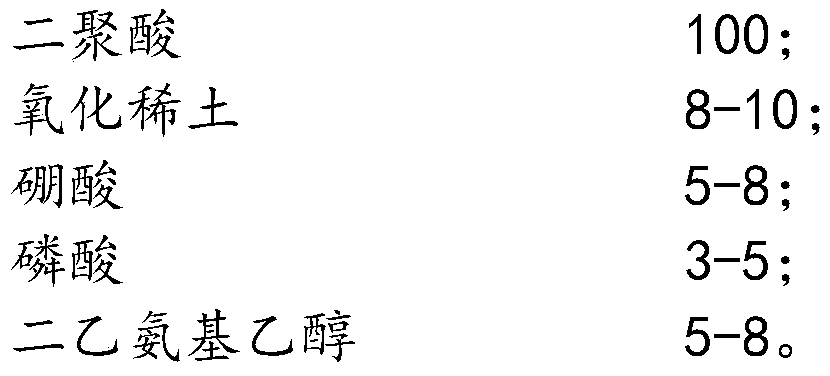

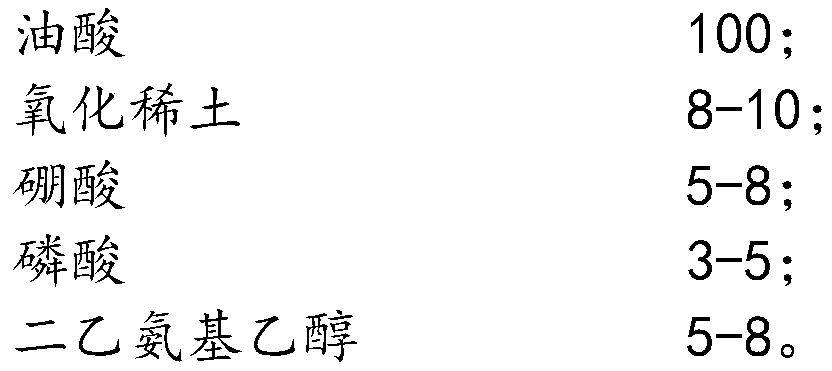

The invention provides a lubricant composition. The lubricant composition is characterized in that the lubricant composition prepared from the components in parts by weight: 100 parts of ricinoleic acid, 8-10 parts of rare earth oxide, 5-8 parts of boric acid, 3-5 parts of phosphoric acid, and 5-8 parts of diethylaminoethanol. The prepared lubricant composition is a boron-phosphorus-rare earth friction modifier, an anti-rust agent, and is also a good surfactant due to the fact that the ricinoleic acid has the characteristics of -OH, -COOH and unsaturated bonds, C long chain and the like. The invention further provides preparation of trace lubricant by using the lubricant composition. The preparation is characterized in that the lubricant composition further includes the components such asisodecyl isodecanoate, sodium cocoyl glutamate, maleic acid ricinoleate, propylene glycol alginate, and myristyl alcohol; the trace lubricant prepared by the lubricant composition can meet the requirements for lubrication cooling, extreme pressure abrasion resistance and rust prevention of metal processing; and the use amount of the lubricant can be saved more than 90% used with a trace lubrication device.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

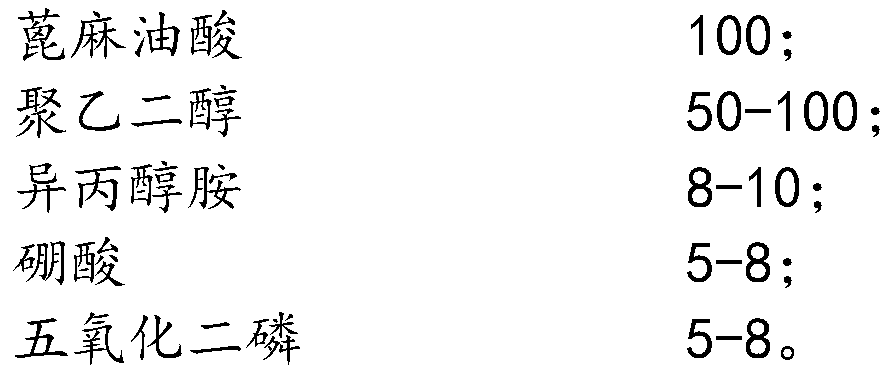

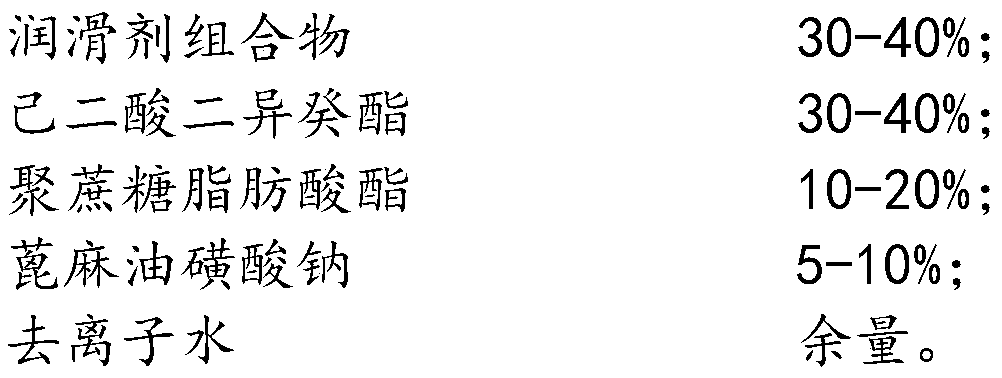

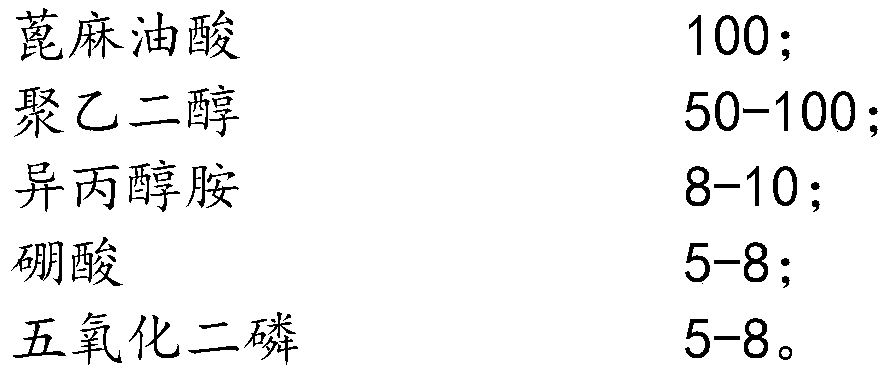

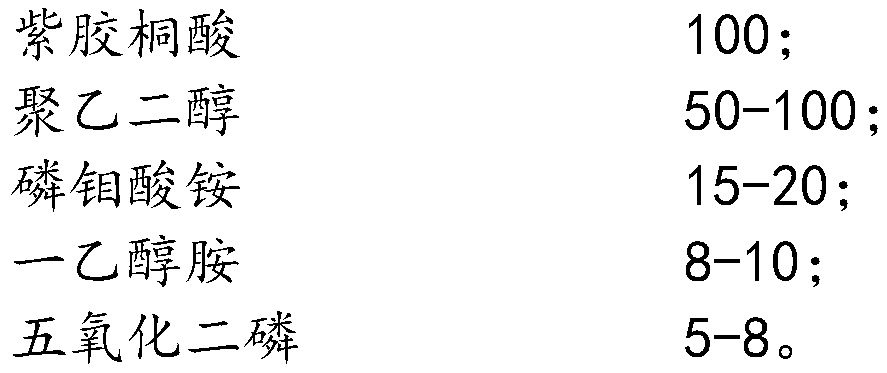

Phosphorus-boron-nitrogen-containing lubricating composition minimal quantity lubricant and preparation method thereof

PendingCN111040828AImprove the lubrication effectPromote degradationAdditivesActive agentPolyethylene glycol

The invention provides a lubricant composition. The lubricant composition is prepared from, by weight, 100 parts of ricinoleic acid, 50-100 parts of polyethylene glycol, 8-10 parts of isopropanolamine, 5-8 parts of boric acid and 5-8 parts of phosphorus pentoxide. The lubricant composition prepared in the invention is a B-P-N type friction modifier and an antirust agent, and is also a good surfactant. The invention also provides a minimal quantity lubricant prepared from the lubricant composition. The minimal quantity lubricant is characterized by also containing diisodecyl adipate, polysucrose fatty acid ester, castor oil sodium sulfonate, deionized water and other components. The minimal quantity lubricant prepared in the invention can meet the requirements of lubrication cooling, extreme pressure wear resistance and rust prevention in metal processing; and the usage amount of the lubricant can be saved by 90% or more when the lubricant is matched with a minimal quantity lubricationdevice.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

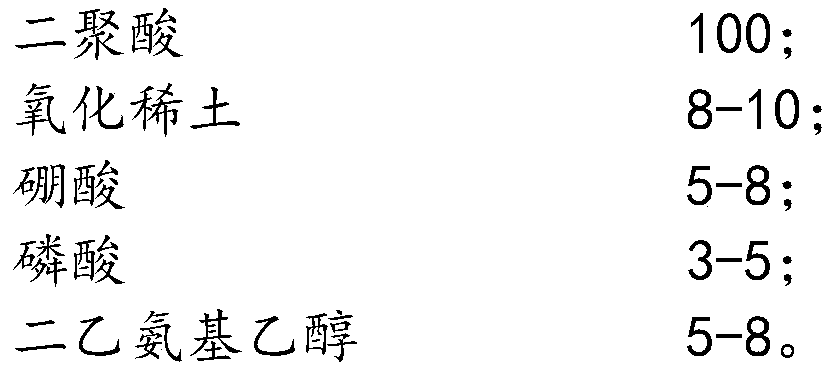

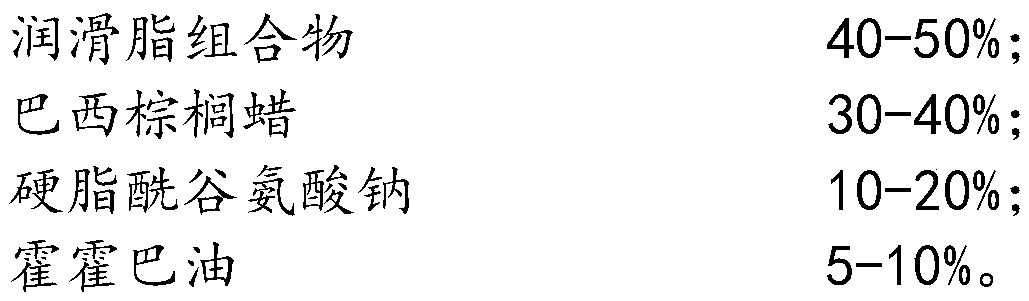

Repairable lubricating grease and preparation method thereof

ActiveCN110373249AImprove the lubrication effectImprove rust resistanceAdditivesPhosphoric acidRare earth

The invention provides a lubricating grease composition. The lubricating grease composition s characterized in that the lubricating grease composition is formed by preparing dimer acid, rare earth oxide, boric acid, phosphoric acid and diethylaminoethanol, and the lubricating grease composition is prepared from the components in parts by weight: 100 parts of the dimer acid, 8-10 parts of the rareearth oxide, 5-8 parts of boric acid, 3-5 parts of phosphoric acid and 5-8 parts of the diethylaminoethanol. The invention further provides repairable lubricating grease. The repairable lubricating grease is prepared from the following components in percentage by weight: 40-50% of a lubricating grease composition, 30-40% of carnauba wax, 10-20 % of sodium stearoyl glutamate and 5-10% of jojoba oil. The lubricating grease composition is a boron-phosphorus-rare earth friction modifier, has the effect of repairing abrasion of the metal surface and has good lubricity, rust resistance and biodegradability; the carnauba wax has a high good melting point, good lubricity and degradability; the sodium stearoyl glutamate is a good organic thickener and surfactant to promote biodegradation of other components; and the jojoba oil is a good degradable lubricant.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

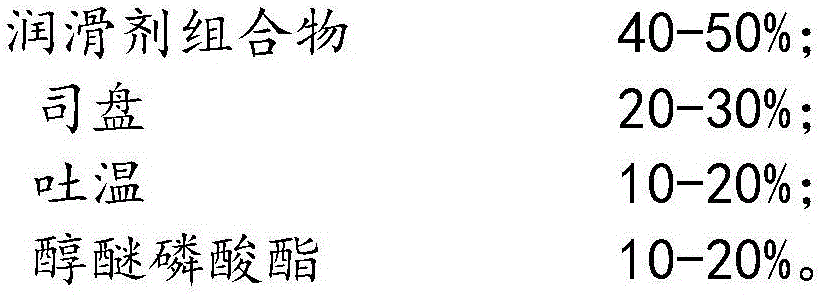

Environment-friendly trace lubricant and preparation method thereof

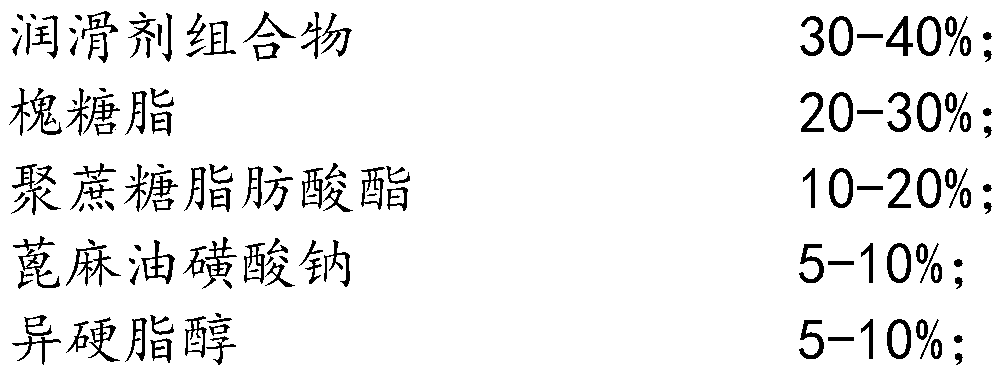

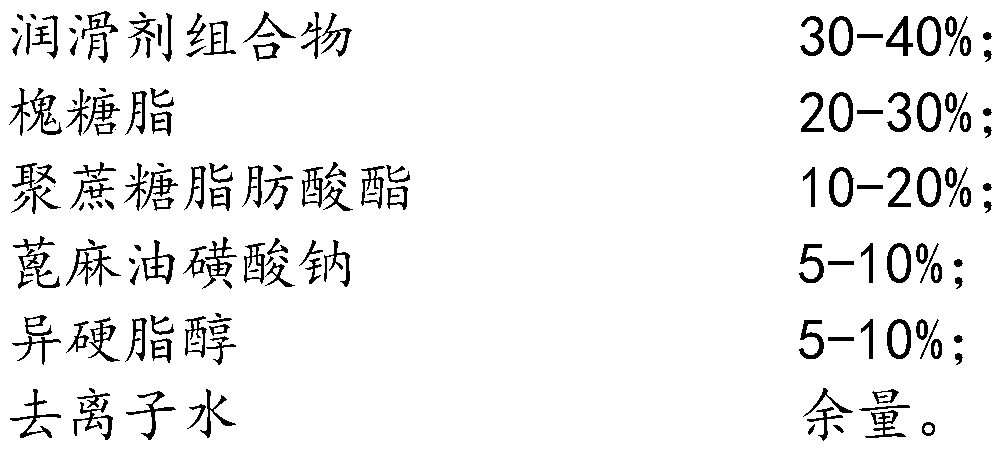

ActiveCN111154542AImprove the lubrication effectPromote degradationLubricant compositionSucroseIsostearyl alcohol

The invention provides a lubricant composition which is characterized by being prepared from lac eleostearic acid and fatty acid, wherein the molar ratio of the lac eleostearic acid to the fatty acidis 1:(1-2). The prepared lubricant composition is lac eleostearic acid fatty acid ester, is a good nonionic surfactant and lubricant, and has good lubricating performance; meanwhile, the biodegradability is good, and the environment-friendly effect is achieved. The invention also provides a trace lubricant prepared from the lubricant composition, and the trace lubricant is characterized by being prepared from the following components in percentage by weight: 30-40% of the lubricant composition, 20-30% of sophorolipid, 10-20% of polysucrose fatty acid ester, 5-10% of castor oil sodium sulfonate, 5-10% of isostearyl alcohol, and the balance being deionized water. The prepared trace lubricant can meet the requirements of lubrication cooling, extreme pressure wear resistance and rust prevention in metal processing; and the usage amount of the lubricant can be saved by 90% or more when the trace lubricant is matched with a minimal quantity lubrication device.

Owner:上海贝能环保科技有限公司

Environment-friendly high temperature grease and preparation method thereof

ActiveCN109439387AHigh molecular weightImprove the lubrication effectAdditivesGlucose polymersD-Glucose

The invention provides lubricating oil composition. The composition is prepared from glucose and dimer acid. The preparation method comprises the following steps: glucose and dimer acid are weighed inproportion, added to a reaction kettle respectively, stirred and heated to 180-240 DEG C for sufficient reaction for 8-12 hours; water is drained 3-4 times under reduced pressure during and after the reaction, and grease composition is obtained. The grease composition can be directly used as environment-friendly high temperature grease. The grease composition has relatively large molecular weight and good lubricity, extreme pressure wear resistance, antirust property and biodegradability.

Owner:山东耐博润滑科技有限公司

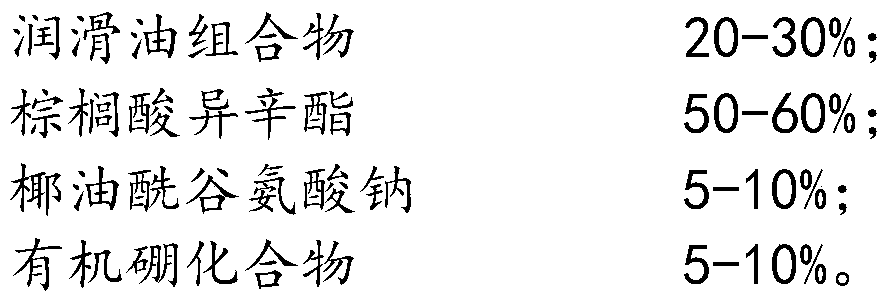

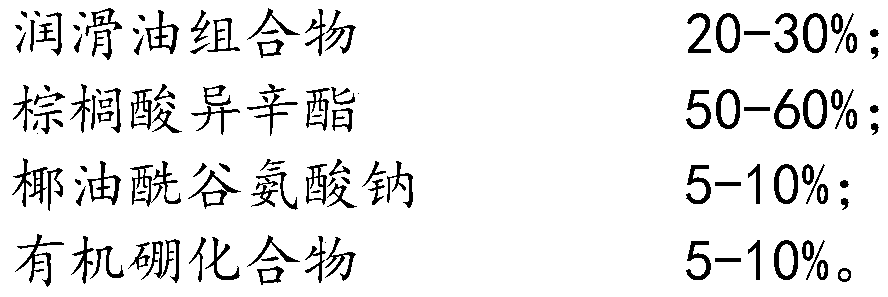

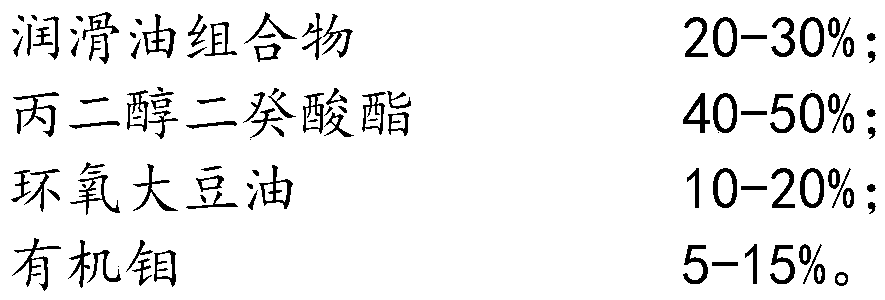

Lubrication oil composition, preparation method of lubrication oil composition and trace quantity lubrication oil prepared by adopting lubrication oil composition

InactiveCN109943390AImprove the lubrication effectPromote degradationAdditivesOctyl palmitateOrganoboron compounds

The invention provides a lubrication oil composition. The lubrication oil composition is characterized by being prepared from fatty alcohol and citric acid, wherein the molar ratio of the fatty alcohol to the citric acid is (1.5-2.5):1. The lubrication oil composition prepared by adopting a preparation method is good in lubricity and biodegradability. The invention provides a trace quantity lubrication oil prepared by adopting the lubrication oil composition. The trace quantity lubrication oil is prepared from the lubrication oil composition, iso-octyl palmitate, sodium cocoyl glutamate, an organoboron compound and other components, and can meet the requirements of metal processing for lubrication cooling, extreme pressure wear resistance and rust prevention; in cooperation with a trace quantity lubrication device for using, the using amount of the lubrication agent can be saved by 95% or above, and the effects of energy conservation, emission reduction and environment protection are significant.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Environmentally-friendly micro cutting fluid and preparation method thereof

ActiveCN109609246AImprove the lubrication effectGood extreme pressure and anti-wear propertiesAdditivesSolubilityPolyester

The invention provides a lubricant composition. The lubricant composition is prepared from the following raw materials: sorbitol, dimer acid and polyethylene glycol, wherein the molar ratio of the above-mentioned sorbitol to the dimer acid to the polyethylene glycol is 1: (2-3): (1-3). By adoption of the lubricant composition prepared by using the method provided by the invention, a synthetic polyester compound has excellent lubricity, good extreme pressure anti-wear properties and excellent water solubility, is also an excellent surfactant, and can completely or partially replace a traditional extreme pressure anti-wear agent containing chlorine, sulfur and phosphorus to be used in an environmentally-friendly micro cutting fluid, so a small amount of the environmentally-friendly micro cutting fluid can meet the requirements of lubrication cooling, extreme pressure wear resistance and rust prevention in metal processing; and by combination of the environmentally-friendly micro cuttingfluid with a micro lubrication device for application, the usage amount of the cutting fluid can be saved by 90% or above, and the effects of energy conservation, emission reduction and environmentalprotection are significant.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Environment-friendly minimal quantity lubricant and preparation method thereof

ActiveCN109810750AGood extreme pressure and anti-wear propertiesGood water solubilityAdditivesSolubilityPhosphate

The invention provides a lubricant composition. The lubricant composition is characterized by comprising chitosan phosphate and an amine salt compound; and chitosan phosphate and the amine salt compound are prepared from chitosan and phosphoric acid, wherein the weight ratio of chitosan to phosphoric acid is (2 to 3) to 1. According to the prepared lubricant composition, since the synthesized chitosan phosphate and amine salt compound are a P-N type extreme pressure antiwear agent, the prepared lubricant composition has an excellent extreme pressure antiwear property and good water solubility,and can all or partially replace a traditional extreme pressure antiwear agent containing chlorine, sulfur and phosphorus to be used in environment-friendly micro-cutting fluid, and a small amount ofenvironment-friendly micro-cutting fluid can meet the lubrication cooling, extreme pressure anti-wear and anti-rust requirements of metal machining. The lubricant composition can save the use amountof the cutting fluid by more than 90%, and has remarkable energy saving and emission reduction and environmental protection effects by being matched with a minimal quantity lubrication device for use.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

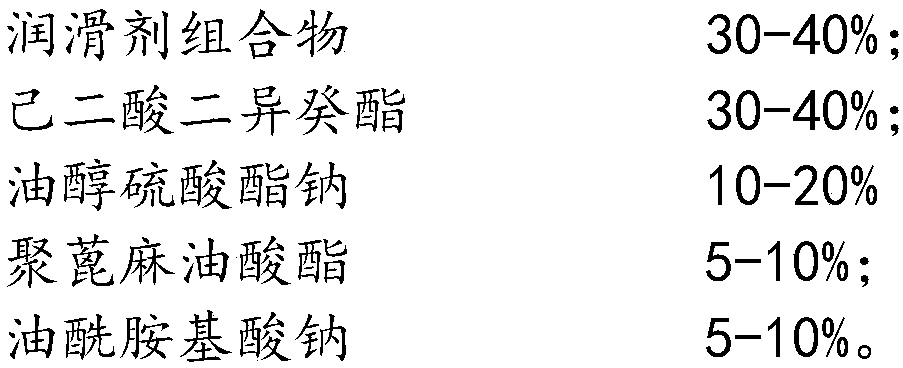

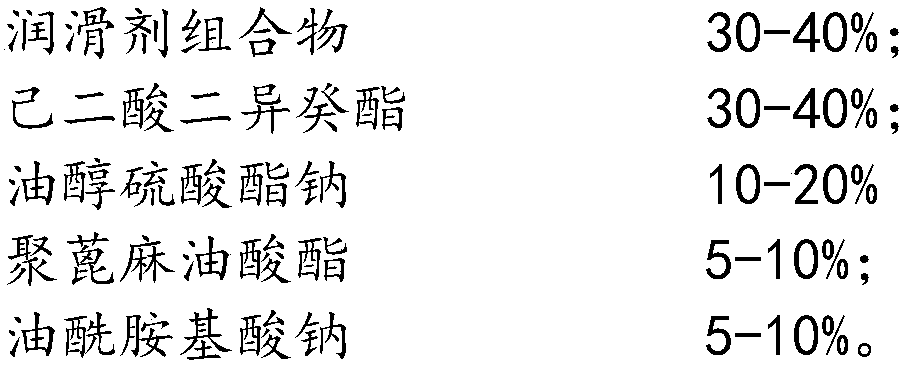

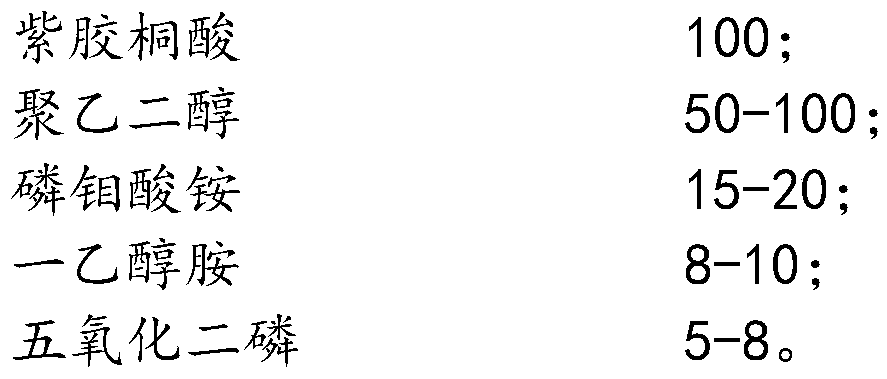

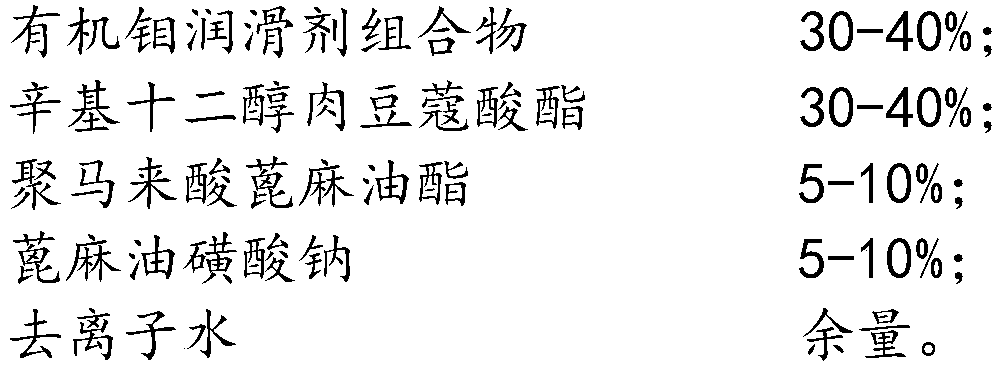

Organic molybdenum lubricant composition trace lubricant and preparation method thereof

The invention provides an organic molybdenum lubricant composition which is characterized by being prepared from the following components in parts by weight: 100 parts of aleutric acid; 50-100 parts of polyethylene glycol; 15-20 parts of ammonium phosphomolybdate; 8-10 parts of monoethanolamine and 5-8 parts of phosphorus pentoxide. The organic molybdenum lubricant composition prepared by the invention is an extreme pressure and antiwear additive containing Mo-P-S-N, has excellent antifriction performance and is also a good surfactant. A trace lubricant containing the organic molybdenum lubricant composition is prepared from the following components in percentage by weight: 30 to 40 percent of the organic molybdenum lubricant composition; 30-40% of octyldodecyl myristate; 5-10% of castor oil polymaleate; 5-10% of sodium sulfonated castor oil and balance of deionized water. The micro lubricant prepared by the invention can meet the requirements of lubrication and cooling, extreme pressure and wear resistance and rust prevention in metal processing; and more than 90% of the lubricant can be saved when used with a micro lubricating device.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

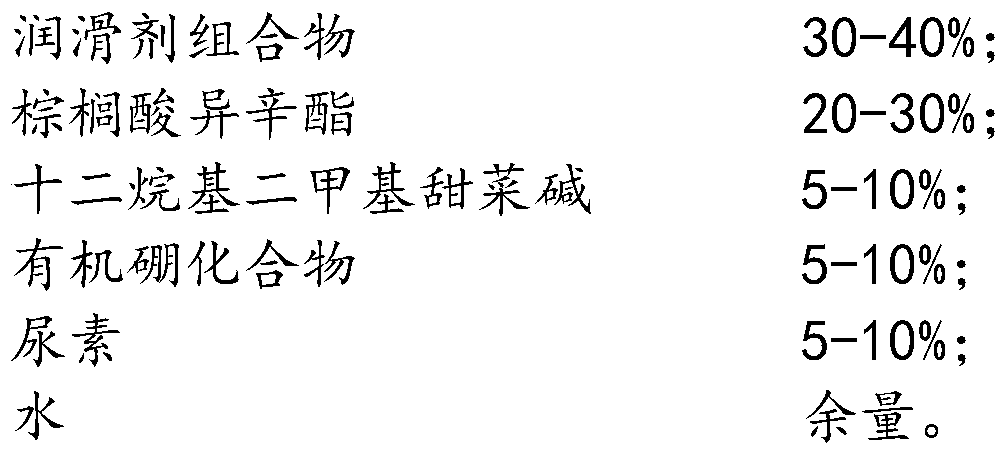

Lubricant composition and preparation method thereof and trace lubricant prepared from lubricant composition

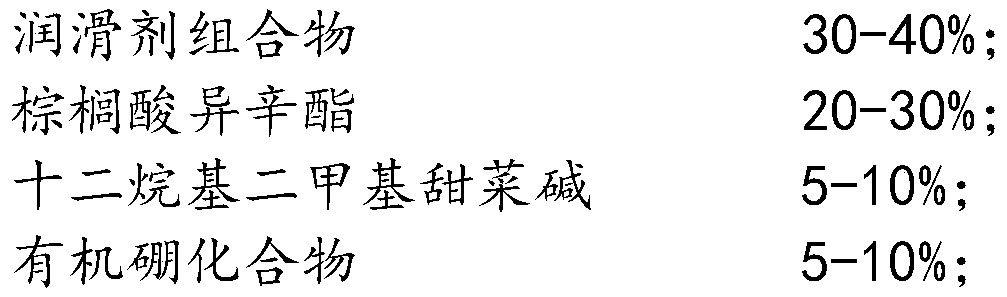

InactiveCN109913302AImprove the lubrication effectGood water solubilityLubricant compositionSolubilityBetaine

The invention provides a lubricant composition which is characterized by being prepared from fatty alcohol, citric acid and polyethylene glycol, wherein the mole ratio of the fatty alcohol to the citric acid is (1-2):1; the weight ratio of the fatty alcohol to the polyethylene glycol is 100:(30-50). The lubrication composition provided by the invention is good in lubricating property and water solubility. The invention further provides a trace lubricant prepared from the lubricant composition. The trace lubricant is characterized by comprising components such as iso-octyl palmitate, dodecyl dimethyl betaine, an organoboron compound, urea and water. The trace lubricant provided by the invention is capable of meeting requirements of metallic processing on lubrication cooling, extreme pressure wearing resistance and rust prevention, and cooperating with a trace lubrication device, the consumption amount of the lubricant can be reduced by 90% or greater, and very remarkable effects of energy conservation, emission reduction and environment protection can be achieved.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

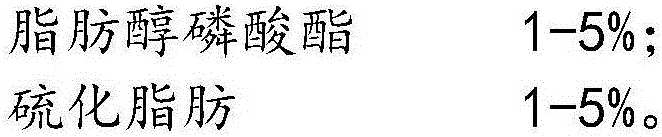

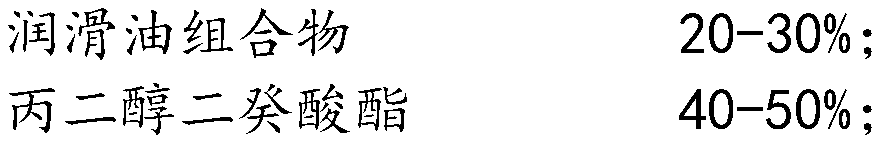

Wear-resistant trace lubricating oil and preparation method thereof

PendingCN111925857AGood anti-frictionImprove the lubrication effectLubricant compositionFuranAlcohol

The invention provides an antiwear lubricating oil composition which is characterized by being prepared from nitrilotriacetic acid, fatty alcohol and phosphotungstic acid, and the molar ratio of nitrilotriacetic acid to fatty alcohol is 1: (2.5-3). The weight of the phosphotungstic acid is 1-2% of the total weight of the nitrilotriacetic acid and the fatty alcohol. The antiwear lubricating oil composition is a P-W-N-containing extreme-pressure antiwear additive, has excellent antifriction performance, and can completely or partially replace S and Cl extreme-pressure antiwear agents having adverse effects on the environment. The invention further provides antiwear trace lubricating oil containing the antiwear lubricating oil composition, and the antiwear trace lubricating oil is characterized by being prepared from the following components in percentage by weight: 50-60% of the antiwear lubricating oil composition; and 40 to 50% of 2, 5-furandicarboxylic acid dialiphatic alcohol ester.The antiwear trace lubricating oil prepared by the invention can meet the requirements of lubrication cooling, extreme pressure wear resistance and rust prevention in metal processing; and the use amount of a lubricant can be saved by more than 95% by matching with a minimal quantity lubricating device, and the effects of energy conservation, emission reduction and environmental protection are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Degradable trace lubricating oil and preparation method thereof

ActiveCN109810761AGood extreme pressure and anti-wear propertiesImprove rust resistanceLubricant compositionPhosphoric acidFatty acid

The invention provides a lubricating oil composition. The lubricating oil composition is characterized by being prepared from chitosan and phosphoric acid, wherein the weight ratio of chitosan to phosphoric acid is (2.5-3.5) to 1; and the lubricating oil composition further contains fatty acid of which the amount is 1-1.5 times the weight of the chitosan. The prepared lubricating oil composition has a good extreme pressure anti-wear property and good anti-rust performance and biodegradability, and can completely or partially replace a traditional anti-wear reagent at extreme pressure containing chlorine, sulfur and phosphorus in the degradable trace lubricating oil, and a small amount of degradable trace lubricating oil can meet the lubrication cooling, extreme pressure anti-wear and anti-rust requirements of metal machining; and with the use of a micro-lubrication device, the use amount of cutting fluid can be saved by more than 95%, and the effects of energy conservation and emissionreduction and environmental protection are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

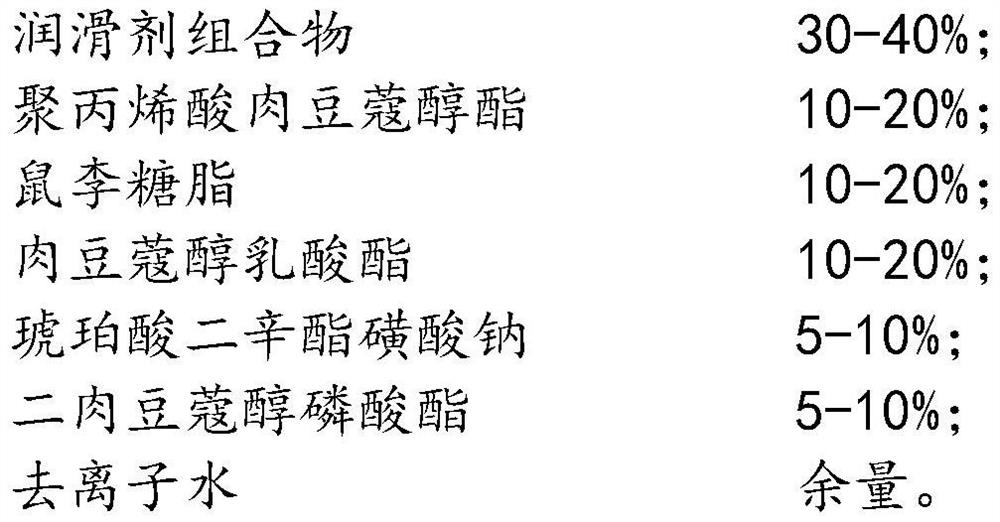

Lubricating oil composition and preparation method thereof and micro lubricating oil prepared thereby

ActiveCN110331027AEffective Modified LifespanPromote degradationLubricant compositionRare earthPhosphoric acid

The invention provides a lubricating oil composition which is characterized by being prepared from the following components in parts by weight: 100 parts of oleic acid, 8-10 parts of rare earth oxide,5-8 parts of boric acid, 3-5 parts of phosphoric acid and 5-8 parts of diethylaminoethanol. The lubricating oil composition prepared by the invention is a boron-phosphorus-rare earth type friction improver and an antirust agent, can modify service life of a tool effectively in metal machining, and is good in degradability. The invention also provides micro lubricating oil containing the lubricating oil composition. The micro lubricating oil is characterized by being prepared from the following components in percent by weight: 5-10% of the lubricating oil composition, 70-80% of isononyl isononanoate and 10-20% of polymethylacrylic fatty alcohol ester. The micro lubricating oil prepared by the invention can meet the lubricating and cooling, extreme pressure wear-resisting and antirusting demands of metal machining. Matched with a micro lubricating device in use, the use level of a lubricant can be saved by over 95%. The effects of energy conservation and emission reduction and environmental protection are obvious.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

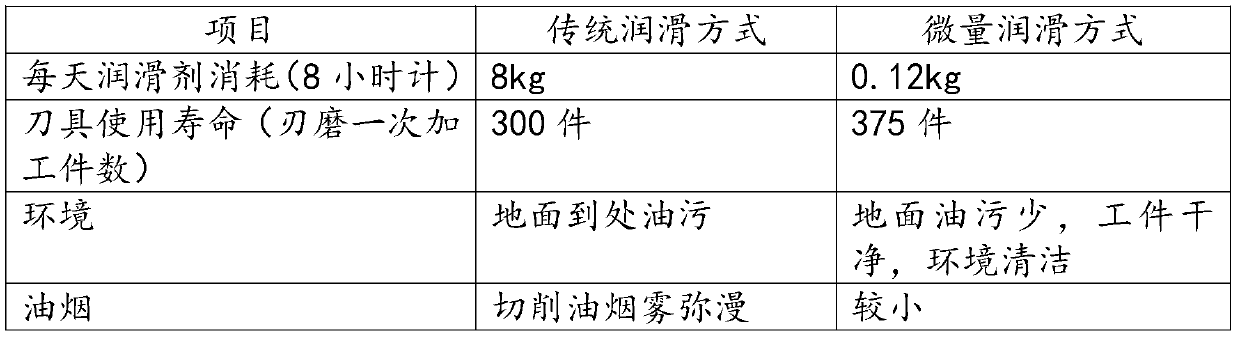

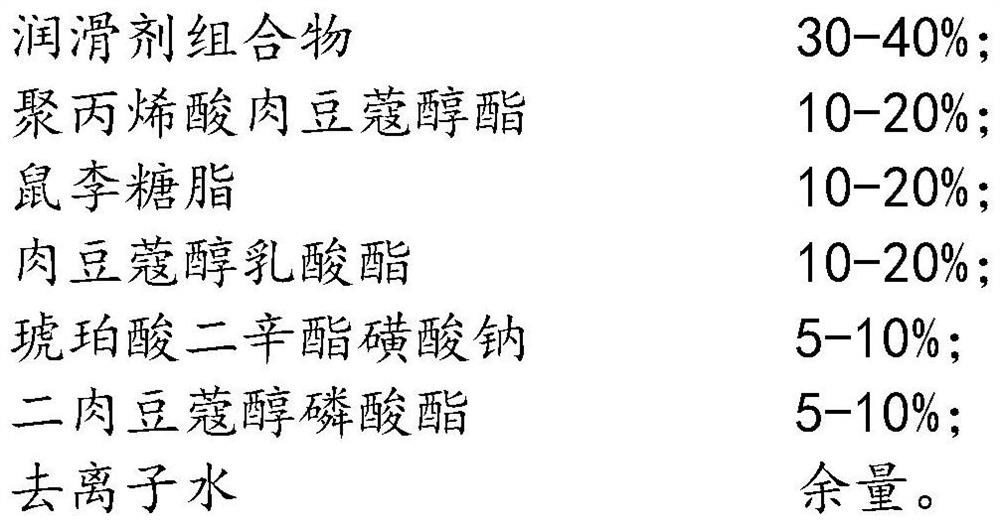

Bio-based environment-friendly trace lubricant and preparation method thereof

ActiveCN112812878AImprove the lubrication effectPromote degradationLubricant compositionPhosphoric Acid EstersPtru catalyst

The invention provides a lubricant composition which is characterized in that the lubricant composition is prepared from konjac polysaccharide and myristic acid; the weight ratio of the konjac polysaccharide to the myristic acid is: 100 parts ofkonjac polysaccharide; and 100-120 parts of myristic acid. The preparation method comprises the following steps: adding konjac polysaccharide and myristic acid into a reaction kettle, adding a catalyst, and reacting for 3-5 hours at the temperature of 180-220 DEG C under the protection of nitrogen; removing moisture under reduced pressure in the reaction process; obtaining the konjac polysaccharide myristate. The konjac polysaccharide myristate is a good nonionic surfactant and lubricant, and has good lubricating performance; meanwhile, the biodegradability is good, and the environment-friendly effect is achieved. The invention also provides a bio-based environment-friendly trace lubricant containing the lubricant composition. The bio-based environment-friendly trace lubricant is prepared from the following components: the lubricant composition, polyacrylic acid myristyl alcohol ester, rhamnolipid, myristyl alcohol lactate, sodium dioctyl sulfosuccinate, di-myristyl alcohol phosphate and deionized water.

Owner:上海贝能环保科技有限公司

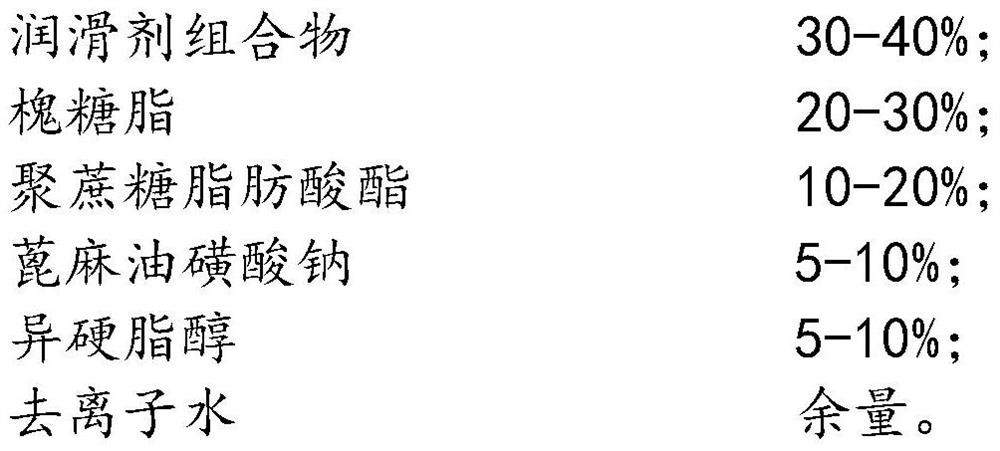

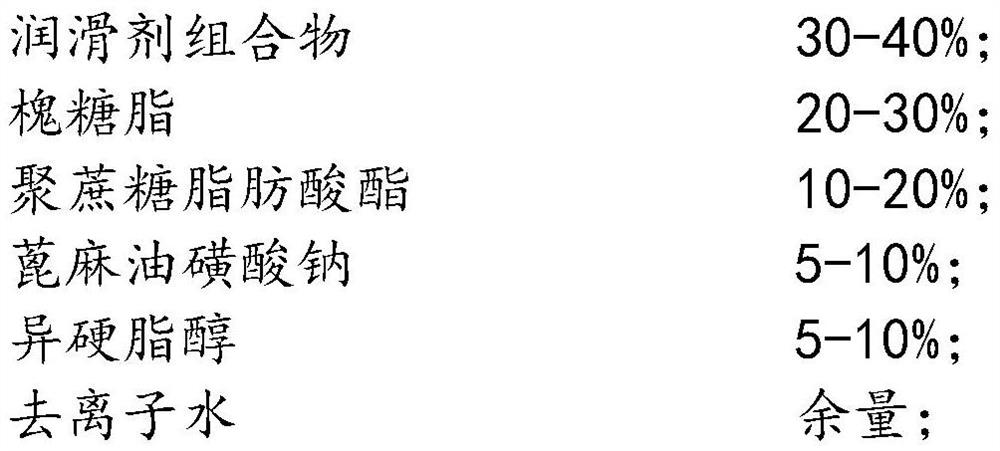

A kind of environment-friendly trace lubricant and preparation method thereof

ActiveCN111154542BImprove the lubrication effectPromote degradationLubricant compositionSucroseIsostearyl alcohol

A lubricant composition provided by the present invention is characterized in that, it is prepared from lac jatrophic acid and fatty acid; the molar ratio of lac jatrophic acid and fatty acid is 1:1-2. The lubricant composition prepared by adopting the invention is a kind of fatty acid ester of lactoic acid, is a good non-ionic surfactant and lubricant, and has good lubricating performance; at the same time, it has good biodegradability and is friendly to the environment. The present invention also provides a lubricant composition to prepare a micro-lubricant, which is characterized in that it is prepared from the following components in weight percentage: lubricant composition 30-40%; sophorolipid 20-30%; polysucrose fat Ester 10‑20%; Sodium castor oil sulfonate 5‑10%; Isostearyl alcohol 5‑10%; Deionized water balance. The micro-quantity lubricant prepared by the invention can meet the lubricating cooling, extreme pressure anti-wear and anti-rust requirements of metal processing; when used with a micro-quantity lubrication device, the amount of lubricant used can be saved by more than 90%.

Owner:上海贝能环保科技有限公司

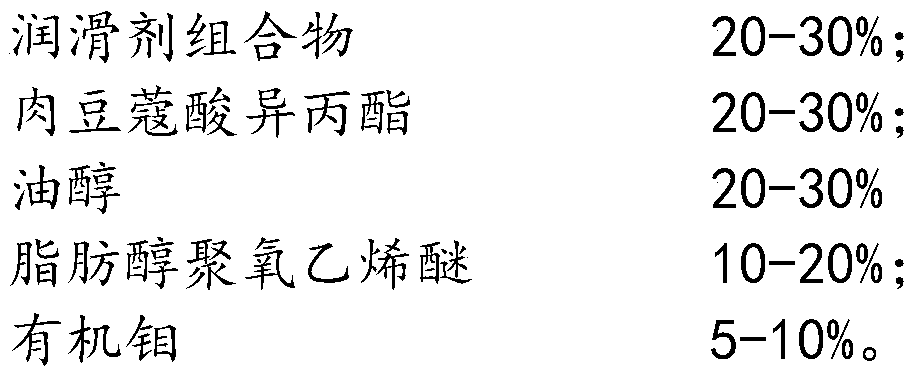

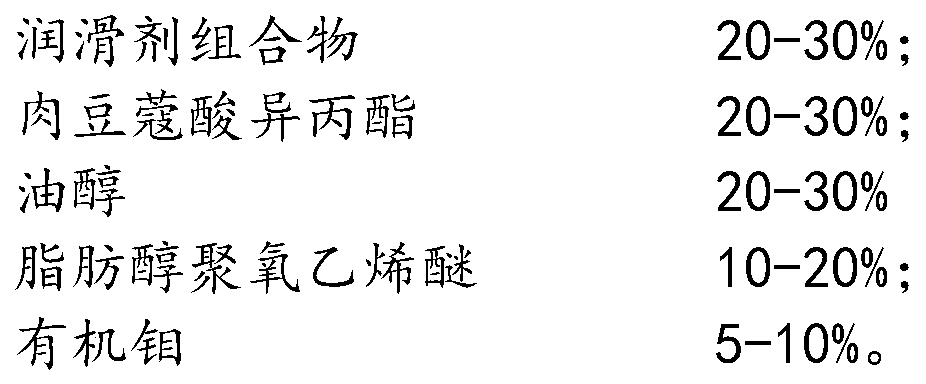

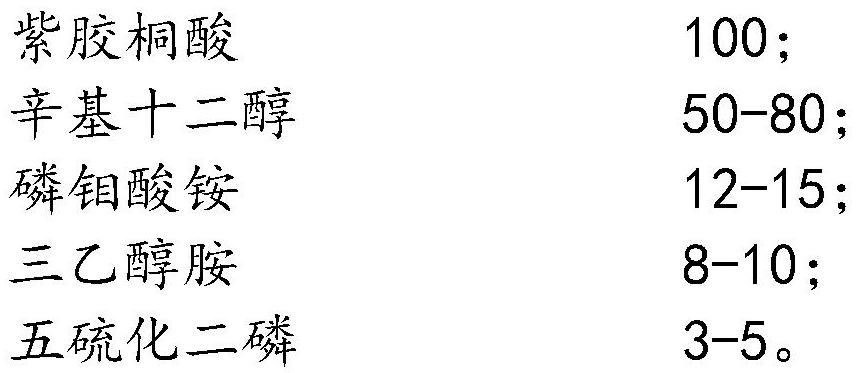

Organic molybdenum trace lubricating oil and preparation method thereof

ActiveCN111484888BGood anti-frictionImprove the lubrication effectAdditivesPhosphorus pentasulfideAmmonium phosphomolybdate

The invention provides an organic molybdenum lubricating oil composition, which is characterized in that, it is prepared by comprising eleostearic acid, ammonium phosphomolybdate, triethanolamine, octyldodecanol, and phosphorus pentasulfide, and the weight parts of the components are The number ratio is: eleostearic acid 100; octyldodecanol 50-80; ammonium phosphomolybdate 12-15; triethanolamine 8-10; phosphorus pentasulfide 3-5. The organic molybdenum lubricating oil composition prepared by the invention is an extreme pressure anti-wear additive containing Mo-P-S-N, and has excellent anti-friction performance. The present invention also provides an organic molybdenum trace lubricating oil containing the above organic molybdenum lubricating oil composition. Isooctyl ester 65-75%; polyricinoleate maleate 10-20%. The organic molybdenum trace lubricating oil prepared by the invention can meet the requirements of lubricating cooling, extreme pressure, anti-wear and rust prevention in metal processing; when used in conjunction with the trace lubrication device, the consumption of lubricant can be saved by more than 95%, and the effect of energy saving, emission reduction and environmental protection is achieved. Significantly.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

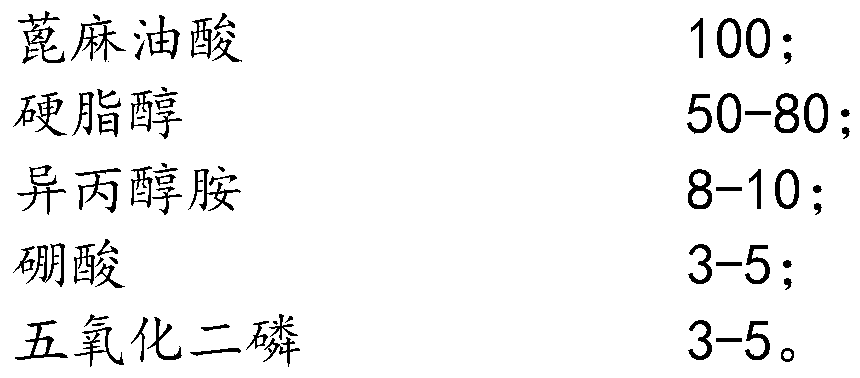

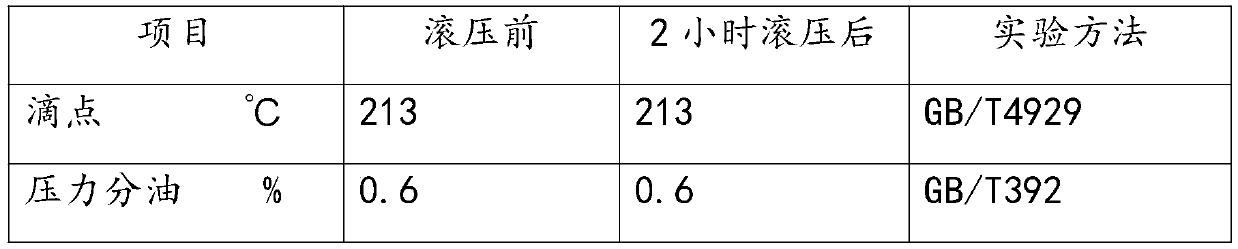

High-temperature environment-friendly lubricating grease and preparation method thereof

PendingCN111040859AGood Pasty Physical FormExcellent ThickenerLubricant compositionSucroseFriction modifier

The invention provides a lubricating grease composition which is characterized by being prepared from the following components (by weight): 100 parts of ricinoleic acid, 50-80 parts of stearyl alcohol, 8-10 parts of isopropanolamine, 3-5 parts of boric acid, and 3-5 parts of phosphorus pentoxide. The invention also provides high-temperature environment-friendly lubricating grease which is characterized by being prepared from the following components (by weight): 40-60% of the lubricating grease composition and 40-60% of polysucrose fatty acid ester. The lubricating grease composition preparedby adopting the preparation method is a B-P-N type friction modifier and an antirust agent, is an excellent thickening agent, is good in degradability, and can ensure that the paste physical form of the lubricating grease is good. The polysucrose fatty acid ester has good lubricity, excellent biodegradability and good friction resistance, and can completely or partially replace S and Cl extreme-pressure anti-wear agents which have adverse effects on the environment.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

High temperature resistant lubricant and preparation method thereof

ActiveCN109825345BHigh molecular weightImprove the lubrication effectAdditivesPolymer scienceDimer acid

The invention provides a lubricating oil composition, which is characterized in that it contains chitosan dimer ester amine compounds; the chitosan dimer ester amine compounds are prepared from chitosan and dimer acid into; wherein the weight ratio of chitosan and dimer acid is 1:3‑4. The present invention also provides a preparation method of the above-mentioned chitosan dimer ester amine compound: weigh chitosan and dimer acid in proportion and add them to the reaction kettle respectively, stir and heat to 180-240°C, fully react for 8-12 Hours, during the reaction and after the reaction, the water is decompressed and discharged 3-4 times, which is a chitosan dimer ester amine compound, and this chitosan dimer ester amine compound can be directly used as a high temperature resistant Grease is used. The high-temperature-resistant lubricating grease prepared by the invention has good lubricity, extreme-pressure anti-wear property, anti-rust property and biodegradability.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

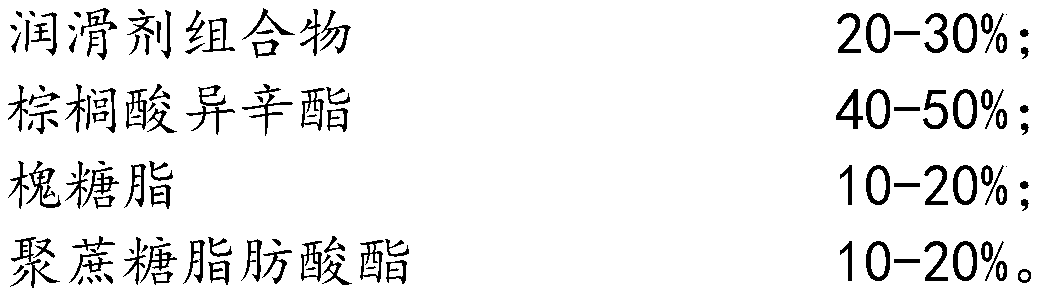

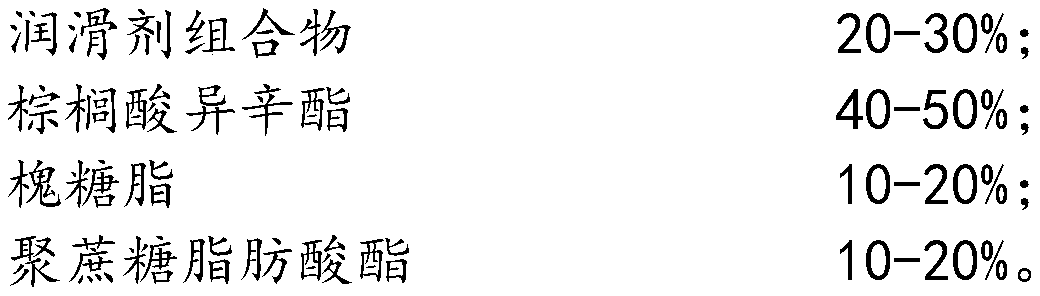

Quasi-dry lubricant and preparation method thereof

ActiveCN111303963AImprove the lubrication effectImprove bindingAdditivesSucroseAmmonium paratungstate

The invention provides a lubricant composition. The lubricant composition is characterized by being prepared from aleutric acid, phosphorus pentoxide and ammonium paratungstate. The weight parts of aleutric acid, phosphorus pentoxide and ammonium paratungstate are 100 parts, 10 to 15 parts, and 5-10 parts, respectively. The prepared lubricant composition is an anti-wear extreme-pressure organic tungsten additive containing P-W-N, three -OH in the molecular structure of the aleutric acid is beneficial for an esterification reaction of the aleutric acid with phosphorus pentoxide, and -COOH in the molecular structure of the aleutric acid is easy to be combined with -WO3- in ammonium paratungstate so as to generate organotungsten compounds. Tests prove that the service life of a cutter can beeffectively prolonged when the lubricant composition is used for quasi-dry lubrication of the cutter. A quasi-dry lubricant containing the lubricant composition is characterized by being prepared fromthe following components in percentage by weight: 20-30% of the lubricant composition, 40 to 50% of isooctyl palmitate, 10 to 20% of sophorolipid and 10-20% of polysucrose fatty acid ester.

Owner:上海贝能环保科技有限公司

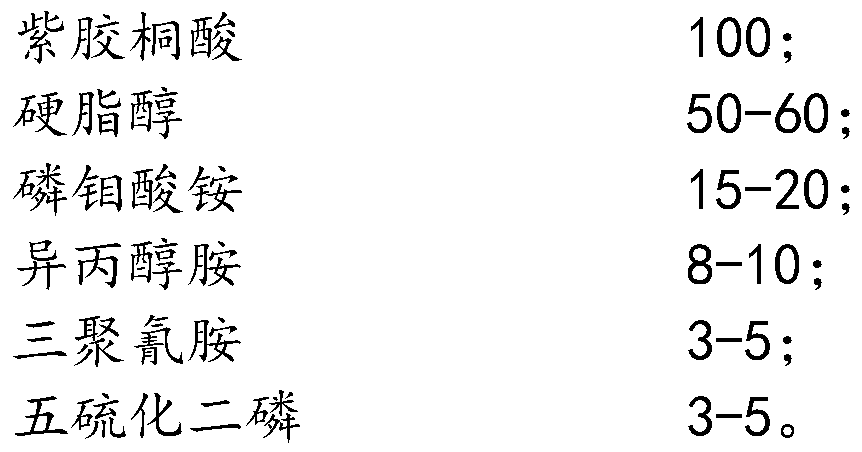

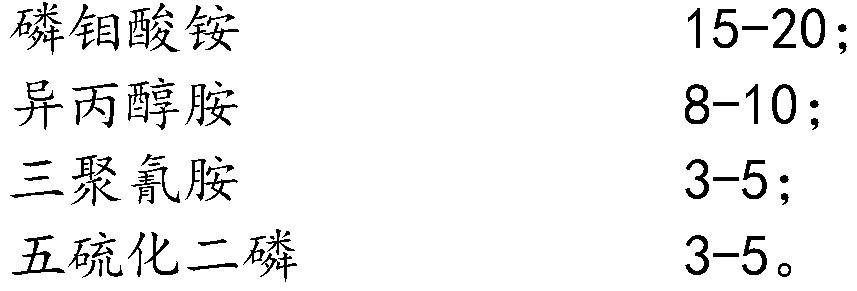

Organic molybdenum high-temperature lubricating grease and preparation method thereof

ActiveCN111394154AGood anti-frictionPaste physical form is goodAdditivesAmmonium molybdateStearyl alcohol

The invention provides an organic molybdenum lubricating grease composition which is characterized by being prepared from the following components shellac eleostearic acid, ammonium phosphomolybdate,melamine, stearyl alcohol, isopropanolamine and phosphorus pentasulfide. The parts by weight of the components are 100 parts of shellac eleostearic acid; 50-60 parts of stearyl alcohol; 15-20 parts ofammonium phosphomolybdate; 8-10 parts of isopropanolamine; 3-5 parts of melamine; and 3-5 parts of phosphorus pentasulfide. The invention further provides organic molybdenum high-temperature lubricating grease containing the organic molybdenum lubricating grease composition, and the organic molybdenum high-temperature lubricating grease is characterized by being prepared from the following components in percentage by weight: 50-60% of the organic molybdenum lubricating grease composition; 30-40% of polymaleic castor oil ester; and 5-15% of molybdenum disulfide. The organic molybdenum lubricating grease composition prepared by adopting the preparation method is an extreme-pressure anti-wear additive containing Mo-P-N-S and excellent in anti-friction performance and can ensure that the paste physical form of the lubricating grease is good. The prepared organic molybdenum high-temperature lubricating grease is applied to lubrication of bearings, guide rails and other parts, and the service life of the bearings and the guide rails is prolonged.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Lubricant composition, method for its preparation and preparation of microlubricant by the combination

ActiveCN110373250BImprove the lubrication effectPromote degradationAdditivesMonosodium glutamateO-Phosphoric Acid

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

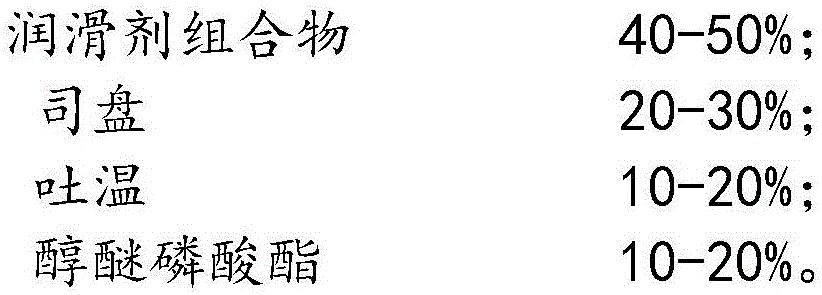

Anti-wear lubricating grease and preparation method thereof

InactiveCN111849588APaste physical form is goodGood anti-frictionAdditivesPolymer scienceFatty alcohol

The invention provides an anti-wear lubricating grease composition which is characterized by being prepared from nitrilotriacetic acid, neopentyl glycol, fatty alcohol and phosphotungstic acid, and the molar ratio of nitrilotriacetic acid to neopentyl glycol is 1: (1-1.5); the molar ratio of nitrilotriacetic acid to fatty alcohol is 1: (0.5-1); the weight ratio of phosphotungstic acid is 1-2% of the total weight of nitrilotriacetic acid, neopentyl glycol and fatty alcohol. The invention also provides an anti-wear lubricating grease containing the anti-wear lubricating grease composition, and the anti-wear lubricating grease is characterized by being prepared from the following components in percentage by weight: 40-50% of the anti-wear lubricating grease composition; 40-50% of poly (2, 5-furandicarboxylic acid) neopentyl glycol ester; and 5-15% of disulfide. The anti-wear lubricating grease composition prepared by the invention is an extreme pressure anti-wear additive containing P-W-N, has excellent antifriction performance, and can ensure that the paste physical form of the lubricating grease is good. The prepared anti-wear lubricating grease is applied to lubrication of bearings, guide rails and other parts, and the service life of the bearings and the guide rails is prolonged.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com